Smart coatings epitomize extraordinary films endowed with predetermined attributes that grant them the faculty to diligently perceive and deftly retort to a panoply of environmental and extrinsic instigations. Additionally, the ‘smart coating’ terminology alludes to the intrinsic prowess of coatings to keenly apprehend their milieu and adeptly comport themselves in consonance with said stimuli. Broadly, the riposte exhibited by these smart coatings is contingent upon a catalyst furnished by the ambient surroundings, encompassing modulations in temperature, humidity, luminosity, chemical or biological impetuses, and the rigors of mechanical duress.

Smart coatings, emblematic of ingenuity, reveal the propensity to harmonize with alterations in the microcosmic realm. Moreover, these coatings proffer abundant latent utilities, including safeguarding against corrosive processes and augmenting ornamental allure. Additionally, they facilitate the creation of functionally graded materials.

Brief Overview Of Smart Coatings

Smart coatings have a wide range of potential applications due to their ability to sense and respond to changes in their environment. Here are some potential applications:

- Corrosion protection: The coatings can protect metal surfaces from corrosion by sensing and responding to environmental changes that could lead to corrosion.

- Decoration: These coatings can be used for decorative purposes, such as changing color in response to changes in temperature or light

- Functionally graded materials: They can be used to create functionally graded materials, which have different properties in different areas of the material

- Smart windows: Such coatings can be used to create windows that can change their transparency in response to changes in light or temperature

- Heat mirrors: Smart coatings can be used to create heat mirrors, which reflect heat while allowing light to pass through

- Overlay coatings: Smart coatings can be used as overlay coatings to provide additional functionality to existing materials, such as self-healing properties

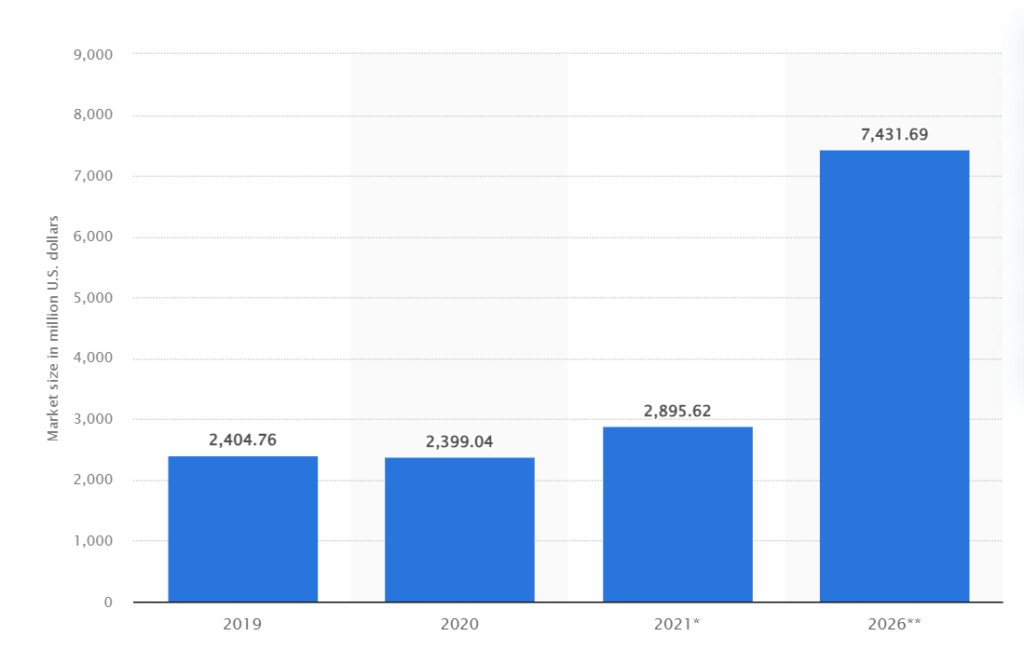

Image: Market size of smart coatings worldwide from 2019 to 2026

In 2021, the worldwide smart coatings market was valued at approximately $2.9 billion, marking a notable 21 percent surge from the preceding year’s valuation of around $2.4 billion. This vigorous growth trajectory is anticipated to persist, with projections indicating that the smart coatings sector will ascend to roughly $7.43 billion by 2026. This projection signifies an impressive surge of about 156 percent compared to the valuation estimated in 2021.

How Smart Coatings Respond To External Stimuli?

Smart coatings respond to external stimuli using various mechanisms and materials to sense and react to environmental changes. Here is an explanation of how smart coatings respond to external stimuli:

- Stimuli-responsive materials: Smart coatings can be designed and prepared by incorporating stimuli-responsive materials, such as light, pH, pressure, temperature, and more. These materials have unique elements that change when exposed to specific stimuli.

- Trigger from the external environment: In general, the response of smart coatings requires a trigger from the external environment. This trigger can be a change in temperature, humidity, light, chemical or biological stimuli, or mechanical stress. Once the trigger is detected, the smart coating initiates a response.

- Spontaneous response: Smart coatings are designed to respond spontaneously to changes in the microenvironment. This means they can react quickly and autonomously to the specific stimulus they are programmed to detect.

- Strategic design: Smart coatings can be strategically designed to respond to internal or external stimuli. This involves carefully selecting and incorporating specific materials and structures into the coating to achieve the desired response.

Different Types Of Triggers That Can Activate Smart Coatings

Various kinds of stimuli can activate smart coatings. Here are some examples:

- Temperature: Changes in temperature can trigger smart coatings. For example, a smart coating on a window could become more opaque as the temperature rises to block out excess sunlight.

- Humidity: Changes in humidity can also trigger smart coatings. For example, a smart coating on a metal surface could respond to changes in humidity to prevent corrosion.

- Light: Smart coatings can be designed to respond to changes in light. For example, a smart coating on a car could change color in response to changes in light, making it more visible at night.

- Chemical stimuli: They can be triggered by chemical stimuli. For example, a smart coating on a medical device could respond to changes in pH to release a drug.

- Biological stimuli: These coatings can also be triggered by biological stimuli. For example, a smart coating on a medical implant could respond to changes in the body to promote healing.

- Mechanical stress: Smart coatings can be triggered by mechanical stress. For example, a smart coating on a bridge could respond to changes in stress to prevent cracking.

Applications

Smart coatings have a wide range of potential applications due to their ability to sense and respond to changes in their environment. Here are some applications of smart coatings:

- Corrosion protection: They can protect metal surfaces from corrosion by sensing and responding to environmental changes that could lead to corrosion.

- Decoration: Smart coatings can be used for decorative purposes, such as changing color in response to changes in temperature or light.

- Functionally graded materials: These coatings can be used to create functionally graded materials, which have different properties in different areas of the material

- Smart windows: These can be used to create windows that can change their transparency in response to changes in light or temperature

- Heat mirrors: Smart coatings can create heat mirrors, which reflect heat while allowing light to pass through.

- Overlay coatings: These coatings can be used as overlay coatings to provide additional functionality to existing materials, such as self-healing properties

- Medical devices: Smart coatings can be used in medical devices to respond to changes in the body, such as changes in pH or temperature

- Aerospace: They can be used in aerospace applications to detect and respond to changes in temperature, pressure, and other environmental factors

Emerging Technologies And Innovations

Innovative Breakthroughs:

Self-Healing Coatings:

Unveiling a new dimension, self-healing coatings can mend damage autonomously. These intelligent coatings integrate microcapsules containing healing agents within their structure. When subjected to damage, these capsules rupture, releasing agents that seamlessly repair the coating’s integrity.

Sensor-Infused Coatings:

Sensor coatings, pioneers of responsive coatings, have the potential to detect environmental changes and respond instantaneously. Their versatile applications span domains such as aerospace and civil engineering, where they prove invaluable for structural health monitoring.

Hydrophobic Marvels:

Super-hydrophobic variants stand out for their water-repelling prowess among the groundbreaking coatings. Engineered to avert water and other liquids, these coatings find their place in self-cleaning surfaces and safeguard against corrosion.

Microbe-Resistant Shields:

Shaping hygiene landscapes, anti-microbial coatings are intelligent solutions capable of curbing the proliferation of microorganisms on surfaces. In healthcare settings, they play a pivotal role in stemming the transmission of infections.

Shape-Shifting Innovations:

Unveiling the future of coatings, shape memory variants exhibit a remarkable ability to transform in response to external stimuli like temperature or light. Also, their application vistas are wide and transformative, from biomedical implants to aerospace structures.

Electrically Conductive Coatings:

Conductive coatings can transmit electricity, illuminating the path for next-gen applications. Their deployment spans electronics and energy storage, sparking innovation in these sectors.

Nanotechnology’s Impact:

Harnessing the power of nanotechnology elevates smart coatings to new echelons. These coatings redefine performance standards with enhanced properties like durability and self-cleaning attributes.

Adaptive Coatings for Dynamic Surfaces:

Introducing coatings that adapt to external triggers like temperature or humidity, the era of responsive coatings dawns. From smart windows that modulate transparency to adaptive camouflage, the possibilities are limitless.

Energy-Efficiency Champions:

In pursuing greener solutions, innovative coatings emerge as partners in enhancing energy efficiency. Also, by regulating temperature, these coatings revolutionize sectors like building and automotive industries, diminishing reliance on heating and cooling systems.

Future Outlook And Potential Challenges

Future Outlook:

- Anticipated to experience substantial expansion in the foreseeable future, the intelligent coatings sector is poised for remarkable growth. Escalating requisites across diverse automotive, aerospace, and healthcare sectors propel this surge.

- The imminent future promises technological strides to foster the creation of novel, superior smart coatings. These advancements are poised to usher in coatings imbued with elevated attributes and functionalities.

- The realm of smart coatings holds the potential to offer solutions to persisting predicaments, notably corrosion, microbial proliferation, and energy consumption. These coatings are positioned to provide effective resolutions to these longstanding challenges.

Potential Challenges:

- Bridging the gap between theoretical concepts showcased in laboratories and their application in real-world wet coating systems is a pivotal hurdle.

- Smart coatings are tasked with delivering a diverse array of performance attributes, a task that often presents formidable obstacles.

- The considerable expense associated with smart coatings can impede their extensive integration and use.

- The absence of standardized norms and regulatory frameworks in the smart coatings sector can result in product quality and performance discrepancies.

- The dynamic landscape of the smart coatings industry introduces complexities in safeguarding intellectual property, given the perpetual emergence of fresh technologies and innovations.

Conclusion

Smart coatings are crucial in addressing long-standing industry challenges like automotive, aerospace, and marine corrosion protection. They enhance durability and safety, increasing lifespan and reducing maintenance costs in various applications. Also, they offer self-healing properties, extending the lifespan of coatings and reducing the need for frequent repairs. Anti-microbial coatings are essential in healthcare settings to stop the spread of infections while maintaining a clean environment. Also, such coatings with temperature regulation capabilities can improve energy efficiency in buildings and vehicles. Conductive coatings are essential for electronics and energy storage applications. Moreover, these coatings offer advanced functionalities and improved performance, making them vital for industries seeking innovative solutions to enhance their products and processes.