The multilayer coating process is one of the most energy-consuming and high-emission processes. Constant innovations are underway to lower the effect of these two drawbacks. A Wet-on-wet coating system has turned out to be one of the most effective ways to counter these two issues simultaneously. This method applies additional coats before the previous coats have cured. The composite-coated film then cures or dries as a whole. It is used in a few multilayer-coating domains (i.e., automotive, industrial, offshore, etc.) for its strong edge over conventional systems.

These coatings often feature advanced polymer technologies that allow for stronger, more durable bonds between the coating and the surface and improved flow and leveling properties. Another area of advancement has been the development of new application tools and equipment specifically designed for wet-on-wet coating. These tools often feature advanced designs that allow for more precise, even coating applications and improved ergonomics for the user.

The wet-on-wet coating technique allows for smooth, even application of high-viscosity coatings. As the layers are applied in quick succession, the coating molecules can flow and spread more easily, resulting in a smooth, polished finish.

One example is the development of specialized application techniques for different types of surfaces and coatings. For instance, specific techniques are optimal for applying wet-on-wet coatings to porous surfaces, and techniques are best suited for applying coatings with high viscosities.

Overall, the advances in wet-on-wet coating technology and techniques have greatly improved the effectiveness and reliability of this application method. These advancements have created high-quality, durable coatings with a smooth, professional finish, making wet-on-wet coating a valuable tool in various industries.

Wet on Wet Coating – Understanding the Need

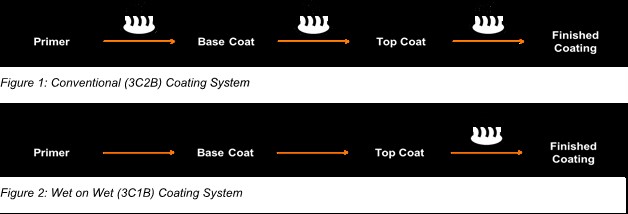

Wet-on-wet coating provides significant advantages over traditional coating systems such as the 3C2B (3 Coat, 2 Bake) system. In 3C2B systems, the coating is exposed to baking after applying each layer.

Subsequent layers are applied after the prior layers have completely dried. On the contrary, a typical wet-on-wet coating instance is a 3C1B (3 Coat, 1 Bake) system. The 3 coats are applied layer by layer and exposed to baking. Single baking saves a significant amount of energy. The application time is also reduced as all the layers are applied layer by layer and exposed to heating at once.

Sustainability Aspects

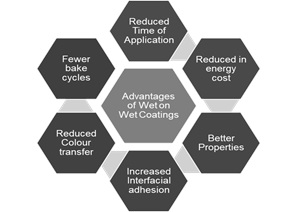

One of the major attributes of wet-on-wet coating is its contribution to sustainability.

The factors include:

- Reduction in VOC (Volatile Organic Compound): The Wet-on-Wet coating system provides a compact coating system, reducing the amount of coating and subsequently reducing the amount of volatile material released.

- Energy Reduction: Less baking leads to less energy requirement.

- Cost Saving: Wet on Wet coating system doesn’t require sanding or baking between two consecutive coats (e.g. epoxy coats). The unwanted sanding and baking save much energy, leading to cost savings.

Performance Aspects

A Wet-on-wet coating system imparts a few enhanced performance aspects compared to conventional coatings.

- Interfacial Adhesion: The interlayer adhesion force between layers is superior to that of the conventional coating system because of the homogeneity of layers during application. The wet layers bond with each other to a greater extent than the solid and wet layers, which increases overall performance.

- Reduced Colour transfer: The increased interfacial adhesion results in reduced colour transfer to adjacent layers.

Performance and Longevity

An exemplary coating system can better understand the performance and longevity of the wet-on-wet coating.

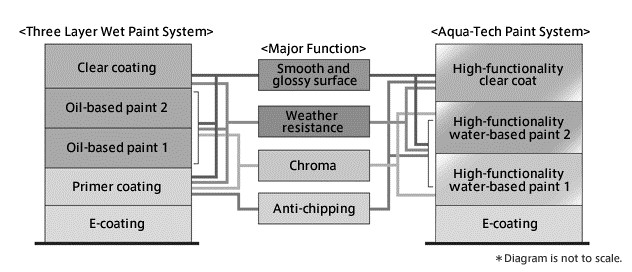

Aqua-Tech Paint System by Mazda: Aqua tech paint system is a waterborne coating system designed for sustainability and performance.

Features:

- VOC emissions have been significantly reduced. This process combines the primer coating process with that of the base and clear topcoats. All three layers are applied in succession and baked to a fine finish.

- Extremely accurate paint control technology with a highly efficient robotic coating system.

- The use of low molecular weight coating resin helps reduce the paint viscosity. By developing this low-solvent water-borne paint, Mazda has significantly reduced VOC emissions.

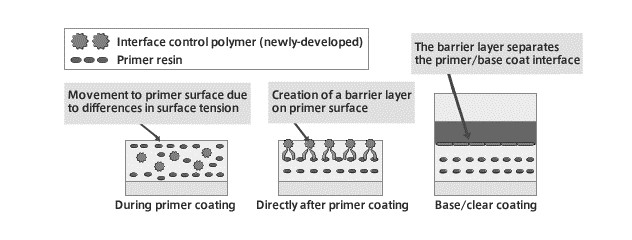

- To prevent degradation of glossiness and colour after primer and base coat application, an interface control polymer is added to the primer to facilitate smooth interaction of primer and base coat interface without hampering any property.

Advantages of Aqua tech Coating System:

- Up to 57 percent reduction in VOC compared to conventional 3-layer coating

- High reliability and durability

- 34 percent reduction in VOC by the implementation of energy-saving Paint Booth Air Conditioning

- Easy optimization of heating in the flash-off step by implementing infrared heaters, which reduce up to 17 percent CO2.

- Improvement in Coating Efficiency: excellent repeatability

Key Players

The wet-on-wet coating method is more of a method/technique than a product. Key players include the companies developing the coating and the end user. Based on innovations in this technique, a few key players are listed.

1. PPG: PPG developed a B1:B2 compact paint system that eliminates the need for primer by enhancing the properties of the two basecoat layers. The B1 and B2 layers are applied wet-on-wet without a heated flash-off zone. Regarding IP presence, PPG has filed ~30 patents on the wet-on-wet concept in the last five years.

2. Axalta: Axalta’s 2-Wet Monocoat System is designed to increase productivity with reduced energy use and paint shop footprint. The process begins with a layer of 2-Wet primer followed by a no-heat, ambient flash. The vehicle is then coated with the 2-Wet Monocoat, coating followed by a bake cycle. Coating applications are reduced from three to two, and the number of drying steps from two to one. Axalta has filed ~five patents in the last 5 years revolving around the wet-on-wet concept.

3. Mazda: Mazda has developed a wet-on-wet coating using waterborne coating in all the layers to reduce emission and surge sustainability. However, Mazda has not been very active in IP filings in recent years in the domain of wet-on-wet coating

Yay or Nay?

The concept of wet-on-wet coating technology has been implemented for a long time, and constant innovation is needed to improve performance and efficiency.

However, stringent regulations for VOC emissions and a lack of skilled professionals are some of the obstacles facing the global automotive refinish coatings market.

Despite its use in many domains, multilayer coating is mostly used in the automotive sector because of a few limitations. The coating process is very parameter-sensitive. In the case of automotive coating, the interval between the applications of different layers is less, and the coating is exposed to baking immediately.

It isn’t easy to replicate the same coating process outdoors or in normal conditions, as this will severely impact the coating’s performance.

There is a need to optimize the coating process to increase its adaptability in various other domains.