Solar energy is a significant contributor to renewable energy, with 29%. Solar panels, however, need to be cleaned frequently to meet the designed parameters. Various automatic cleaning methods have been developed with advancements in technology. This article briefly overviews innovations and methods for self-cleaning solar panels.

The solution combines the passive self-cleaning surface with other physical effects, such as electrical, mechanical vibrational, magnetic, and acoustic wave fields.

Self-cleaning Solar Panels Background

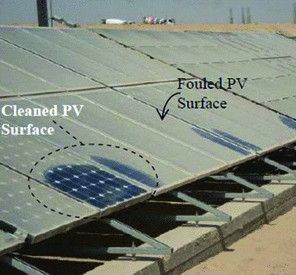

Solar panels generate electricity by permitting light into the solar cells. The more light that strikes a panel, the more power it produces. This reduces the amount of light that hits the panel and, thus, its output.

Because of the upward elevation of the solar panels, they are more prone to bird droppings and a build-up of general dust and debris that does not wash away with rain. Because the anticipated energy figures reported by solar panel manufacturers and installers are based on the ideal performance of clean solar panels, dirt build-up can hurt the panel’s capacity to match those forecasts. As a result, cleaning solar panels is critical to protecting your investment and achieving maximum output. Dust, grime, pollen, and other particulates that accumulate on the solar panel significantly reduce the conversion efficiency of solar panels, which typically operate in the range of 20%. Also, it has been reported that a dust layer weighing 4 grams per square meter can cause a 40 percent decrease in solar power conversion.

Overall, cleaning solar panels increases the direct sunlight they receive, resulting in a corresponding rise in the number of energy units produced by the panels. Moreover, per estimates, it is possible to get a 25% increase in output energy or a 15% to 20% increase in conversion efficiency with adequate cleaning solutions.

Challenges for Solar Panels

Cleaning solar panels with water is the most popular and traditional method; however, cleaning becomes tough, demanding, and costly due to water scarcity in deserted areas. The existing solutions can pose challenges, such as:

- Cleaning cost: The cost of solar panel cleaning varies and is estimated to be $5-$20 per panel every time.

- Water scarcity: Most solar projects are in regions with high solar energy, and these regions predominantly suffer from water scarcity issues.

- Frequent cleaning: The frequent sandstorms in the region demand frequent cleaning of solar panels. Thus, leading to a lot of time consumption.

- Others: Cleaning with chemicals is hazardous to the environment.

As a result, businesses are exploring novel cleaning procedures such as electrical, mechanical, chemical, and electrostatic.

Self-cleaning Solar Panels Solutions

Various automatic solar cleaning methods have been developed to resolve the abovementioned challenges. Self-cleaning technology can be broadly classified under two sections:

- External Field Excitation

- Chemical Coating

External Field Excitation:

1.) Electrical Field: The system takes advantage of the fact that most dust particles have an electric charge, particularly in dry environments. A transparent electrode material such as indium tin oxide delivers an alternating current to the top surface of the panel. Basically, as it swings between being positively and negatively charged, it creates an electric field that repels positively and negatively charged particles. The electric field also helps to impart a charge to uncharged dust particles, allowing them to be quickly repelled as they come in contact with the panel.

2.) Magnetic Field: Several techniques leverage the dipolar magnetic momentum of dust particles to clean the solar array actively. For instance, when subjected to an external magnetic gradient, magnetic dipoles experience a force. Moreover, by generating an external magnetic gradient through strategically placed permanent magnets or solenoids, generating the driving force needed to dislodge dust particles from the solar array becomes possible. Magnets are particularly effective in removing fine dust particles.

3.) Acoustic Field: The system consists of ultrasonic devices installed in pairs or multiple pairs on opposite sides to create a predetermined inclination angle. Additionally, one side generates ultrasonic waves to induce resonance, causing the entire ultrasonic cleaning device to vibrate the glass. Meanwhile, air curtains are generated at both ends of the glass to be cleaned, effectively blocking external foreign substances and maintaining airflow.

4.) Vibration Technology: Vibrating the solar modules effectively removes accumulated dust and sand. This can be achieved by utilizing a piezoelectric element to generate vibrations in the solar module. Applying ultrasonic frequencies to the module can also induce vibrations for effective cleaning.

| S. No. | Technology | Installment Cost | Power Consumption | Surface Damage | Efficiency Improvement | Removal of Dust Particle Size | Maintenance Cost | Additional Information |

|---|---|---|---|---|---|---|---|---|

| 1 | Electrical (ECS) | High | Low | Drop in efficiency after six weeks | Up to 90% | Less than 0.2 mm | Significant cost of maintenance | External work to clean sticky and large particles |

| 2 | Acoustic | Low | Low | No surface damage | Up to 54% improvement in terminal voltage of panel | 0.2 mm and above | Moderate | Transferring of smaller particles is more complex than that of larger sizes |

| 3 | Vibration | Low | Low | Risks of PV panel damage | Drop in efficiency after 6 weeks | – | High | Reduces the cleaning frequency (4 times per month) |

| 4 | Magnetic Field | In Research | – | – | – | – | – | – |

Chemical Coatings:

Engineers are investigating self-surface-cleaning methods other than traditional cleaning to mitigate surface soiling and improve PV module efficiency.

1.) Hydrophobic: A hydrophobic coating operates on the principle of forming a barrier that prevents water from adhering to the surface of solar panels. As a result, water accumulates on the surface in a nearly spherical shape but cannot adhere due to the barrier. Consequently, when the treated surface is tilted, the water rolls off, carrying dirt and dust particles away, similar to a sphere rolling down a slide.

2.) Hydrophilic: Hydrophilic coatings chemically break down dirt when exposed to light, known as photocatalysis. The glass cleans itself in two stages. Evidently, the “photocatalytic” stage of the process breaks down the organic dirt on the glass using ultraviolet light and makes the glass super-hydrophilic (normally, glass is hydrophobic). During the following “super-hydrophilic” stage, rain washes away the dirt, leaving almost no streaks, because water spreads evenly on super-hydrophilic surfaces.

Proposed Solution

Scientists at the University of Washington proposed a solution that chiefly uses a “biomimetic” method to build surface coatings that mimic the micro-nanomorphologies of lotus plant leaves, rice leaves, butterfly wings, and springtail cuticles, taking inspiration from nature. Further, it can be combined with any external field, such as mechanical vibration.

Hydrophilic curved rungs are patterned on the hydrophobic background on the substrate (silicon wafer or soda-lime glass). Moreover, it’s a combination of perfluoro-octyltrichlorosilane (FOTS)–trimethylsilanol (TMS) self-assembled monolayer (SAM) system and a Cytop–TMS spin-coated thin-film system was used. This feature is termed an anisotropic ratchet conveyor (ARCs).

Mounting the ARC patterned wafer on a vibration stage enables water droplets to overcome gravity and ascend inclined surfaces. Chiefly, this is achieved through orthogonal vibration, allowing the droplets to climb surfaces with a maximum inclination angle of 15 degrees. Emphatically, the droplets will travel along the defined zig-zag pattern, looping around the cleaning area.

Depending on the application requirements, one can implement different ARC track designs. All things considered, they help guide the movement path of droplets. These designs effectively collect surface contaminants. The dirty droplets can then be directed off the edge of the cover glass or collected at the end of an ARC track without creating a looping path.

Active Universities

- Boston University: Boston University is developing electrostatic technology to automatically and continuously remove dust from solar panels without requiring water or moving parts.

- Scotland’s Heriot-Watt University: Researchers at Scotland’s Heriot-Watt University have developed a waterless self-cleaning technology for PV panels. It also involves vibration to remove dust and sand by exciting fundamental frequencies in the modules.

Other Applications:

Generally, self-cleaning technologies have applications in various areas, including removing water droplets, grease, and grime from transparent surfaces. Touchscreen displays are used in ATMs, public vending machines, and other devices commonly used for cleaning. Additionally, these technologies are utilized to clean household and office window glass. At the same time, Apollo Power, a startup in Israel, opened up a world of opportunities for ultra-thin panels on sidewalks, reservoirs, greenhouses, golf carts, and even airplanes or car roofs.

Conclusion

Summing up, solar energy firms are frequently partnering with nano-coating development companies to extend the life of their solar plants’ energy output. technology like transparent solar panels are making its way into the market. Without a doubt, researchers are actively conducting extensive research to identify the most effective and cost-efficient solar panel cleaning system. Also, combining coating technologies with any external electrical field excitation technology is a promising path to a long-term solution. We may see more of these technology pairings in the future, as well as the application of AI for more optimal solutions. However, the high cost of coating and the complexity of materials remain challenging.