In the field of material science, self-healing materials are pioneering applications that can repair themselves without external intervention. These materials can recuperate from physical injuries such as scratches or fractures through natural mechanisms initiated by the damage itself. The idea of self-healing materials is drawn from biological systems where organisms can regenerate and fix tissues.

Types of Self-healing Materials

Self-healing properties can be divided into intrinsic and extrinsic properties. The material itself can go through some chemical or physical processes to repair itself, which is called intrinsic self-healing. For instance, reversible chemical reactions like polymerization or depolymerization. Conversely, in extrinsic self-healing materials, the inclusion of external agents or capsules filled with healing agents within the material is involved. Where harm occurs, these capsules break, thereby releasing the recovery agents that fill and mend the damaged areas.

Industrial Application & Challenges

A vast number of industrial applications are associated with self-healing materials. In the field of electronics, such materials increase a device’s durability and lifespan. The utilization of self-healing materials in infrastructure and construction makes a structure more resilient and long-lasting, which can reduce the frequency of repairs. Self-healing aircraft equipment materials can help the aerospace sector cut costs by extending maintenance intervals.

The automotive industry is one of the key users of self-healing materials. A combination of conventional and self-repair technologies has shifted dramatically in this sector. Self-healing cars are one of the most amazing developments in this area. It can diagnose physical damage through its healing property that repairs itself remotely from its central brain via a wireless communication system installed on it. Due to these capabilities, these vehicles have very low maintenance costs, and extended life spans.

Despite the promising advancements, some hurdles still stand in the way of realization and widespread use in making self-healing materials. The scalability, cost, and customization for specific applications are also factors that need more research and development. Nevertheless, such materials are anticipated to repair themselves as technology progresses, thus leading to new sustainable solutions with long-lasting properties.

How do Self-healing Materials Work?

A self-healing material can function in many different ways, which are discussed below:

Self-healing by agent encapsulation – The most common method uses capsules that release the healing substance when the material gets damaged or ruptured. The tiny capsules are incorporated with the conventional coating materials that contribute to its self-healing powers. However, in this method, the size of the capsules is essential; being too large can damage the existing properties of the material. Furthermore, it can be utilized only once, which is undesirable if a material is expected to sustain damage repeatedly.

Self-healing materials with 3D microvascular networks – The other technique engineers have developed vascular networks, much like the veins on a leaf. When a crack occurs in these microvascular materials, a healing agent enters the vascular network and seals the breach. Although this has shown to be successful, restoring a material is slower. Self-healing polymers – Scientists have created smart or intrinsic polymers that can return to their original properties without outside enticement. These polymers can self-repair because of their unique reversible chemical connections.

How Would Self-Healing Materials Be Useful in the Automotive Industry?

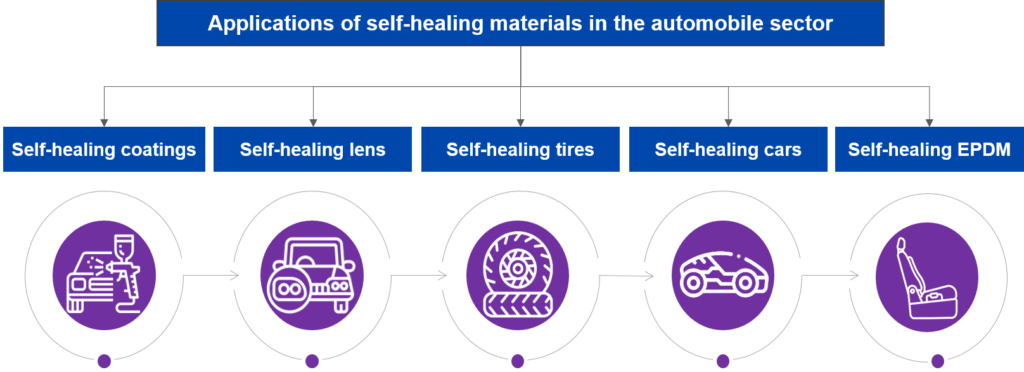

Self-healing materials offer several valuable applications in the automotive industry, such as coatings, lenses, tires, and interior components.

Self-healing Coating:

The Korea Research Institute of Chemical Technology (KRICT) has developed a new coating for car surfaces that can self-heal scratches in just 30 minutes. It performs similarly to commercial protective coatings and self-heals using heat radiation from sunlight. Self-healing coatings work on the idea that light energy is converted to thermal energy and, as a result, vehicle surface temperature rises when exposed to sunlight. Due to the increased surface temperature, the polymer structure’s chemical bonds regularly break down and rejoin, allowing the scratches on the surface to heal themselves. Recently, BMW has developed a car, i.e. BMW iX, which has self-healing properties in its kidney grille, camera technology, radar functions, and other sensors. The grille can heal itself from collision if left alone for some time. Moreover, its grille has a polyurethane coating, reducing its damage vulnerability.

Self-healing Lens:

The Korea Research Institute of Chemical Technology (KRICT) and Kyungpook National University (KNU) joint research team developed a transparent lens material that can remove scratches on the sensor surface within 60 seconds when focused sunlight is irradiated using a simple tool such as a magnifying glass. It was developed to prevent traffic accidents in self-driving vehicles.

Self-healing Tires:

These tires include a unique mechanism that rapidly seals punctures of 5 mm or less in the tread. The mechanism comprises a thick, sticky liquid inside the tire that changes how driving is done. It provides a short-term solution for small punctures brought on by nails, screws, or sharp things. Regardless of your journey’s location, the self-sealing technology ensures a smooth ride until a professional repair is available. This technology is being used by different companies like Michelin, Continental, and JK Tires.

Self-healing Cars:

Lamborghini and the Massachusetts Institute of Technology (MIT) developed a self-healing car, i.e., Terzo Millennio or 3rd Millennium. This car can repair the damage by itself. It includes the suffering of its carbon fiber components – it is primarily made of as are most super and hypercars. Nanotubes incorporated into carbon fiber can carry resin to areas of damage or weakness and prevent cracks from spreading, akin to human blood vessels.

Self-healing EPDM:

EPDM (ethylene-propylene-diene) polymers are smart elastomeric materials that can naturally mend themselves after mechanical harm. Self-healing EPDM, along with other self-healing materials, is also growing in popularity due to its durability and life cycle. The self-healing is done by blending noncovalent ionic cross-linking in elastomer/rubber. These elastomeric materials are used for interiors in automobiles.

Can certain metals self-heal from cuts and fractures the way the human body does? Is it possible to design them so they won’t rust or deteriorate? GE Research is solving this issue by developing immortal batteries and self-healing metals to expand the operational lifetime of critical military systems. To create and demonstrate an immortal battery prototype, GE Research and its partners, the Massachusetts Institute of Technology (MIT), the University of Michigan, the University of California Santa Barbara, and Storagenergy, a pioneer in advanced lithium battery technologies, will make use of artificial intelligence (AI) and machine learning models, mathematics, chemistry, biology, materials science, and extensive experience in battery technology.

Self-Healing Materials: Limitations

Owners of vehicles hoping for an easier, more economical, and more convenient way to maintain their vehicles may soon have their wish granted. Developing self-restoring automotive materials can make routine maintenance much simpler than in the past.

However, several obstacles and restrictions exist while putting them into a vast production. They are as follows:

- Cost of production

- The material’s efficiency

- The scalability of the production process

- Environmental conditions for stimulating self-healing

Conclusion

The possibilities in the automotive repair domain seem inexhaustible in the future. Researchers in automotive engineering have drawn attention to the possibility that these novel materials may possess the ability to self-diagnose and self-repair. It is as good as biodegradable plastics, a sustainable alternative for cars’ Interior.

In the future, complex multi-layer nano-coatings might be applied to vehicle components. These coatings might help in preventing the initial occurrence of more severe harm. There is a lot of potential for developing and applying self-healing materials in the automotive industry. It will undoubtedly transform vehicle repair in the future.