Many economies have focused on bio-economy in the face of ghastly climate change. The U.S.A., E.U., China, Brazil, India, Sweden, Canada, and Finland have recently become more focused on sustainable and circular economies. As part of the bio-economy mix, macroalgae is being used in waste-to-energy technologies to produce sustainable plastics. The first seaweed-based plastic was built by Algopack in 2010, and now over 50 startups/businesses are working towards creating bioplastics. The global blue economy of the seaweed business was estimated at $10.2 billion in 2023, according to Stellarix research. With ever-increasing plastic demand, seaweed biodegradable packaging has become a beacon of hope to combat global plastic bedlam. This blog covers seaweed packaging companies, seaweed packing products, bioplastics research institutes, and future insights.

Seaweed Packaging Companies

Plastic use will reach 1231 Mt in 2060, and industrial packing demand will reach US$ 107 billion by 2033. There are no signs of lowering plastic usage globally, and in a scenario like this, bioplastics made from seaweed are a clear green winner. Below, we share details of some of the key seaweed-based, eco plastic-making companies.

Notpla: London-based Notpla, meaning not plastic, is a company focused on the production of seaweed packaging. Their range of products includes food containers, laundry sachet, ocean paper, Ooho biodegradable/edible liquid packaging, dry food sachet, energy gel pods, food oil pipette, rigid/term packs, rigid cutlery, and bath oil sachet. With approximately 12-13 million in funding via various rounds starting in 2017 (£85000), 10 million (2020), and 1 million Earthshot prize (2022), the company is strengthening its R&D and regenerative company profile.

B’zeos: Switzerland- and Spain-based Bzeos company makes flexible paper coatings, films, thermoformables, and injection molding, among other biodegradable products. The company had various rounds of funding and grants from Mass Challenge Switzerland Accelerator in 2022 (CHK 70K), the Norwegian Research Council in 2022 of 16.4 NOK, and the Ebro Talent Award of £1500 in 2023, among them. The seaweed packaging company B’zeos sources its seaweed, and their in-house biologists and chemists work to convert it into flexible, waterproof, and plastic-like bioplastics.

Sway: A California-based regenerative plastic film-making company has built the TPSea Flex™, which stands for thermoplastic seaweed resin. These bio-based pellets are excellent to replace single-use plastics like food wrappers, polys, retail bags, and food wrappers. They employ seaweed farmers in Maine, United States, for its kelp production. Sway various funding rounds like $5 million in 2024 and first place in the TOM FORD Plastic Innovation Prize and 2021’s Beyond the Bag Challenge.

Carbonwave: The company is currently in the developing phase of bioplastics, yet it is another seaweed-based product that was built – SeaBalance cosmetic emulsifier. The company also had various rounds of funding.

FlexSea: London-based, the company has built Flexseable film that is used in food packaging, cardboard bioplastic windows, personal care products, and textile packing. Their research team tweaks seaweeds’ lipid and oxygen barrier to use them in food packaging. This blue biotech company raised £2.3 million in 2023.

Kelpi: Bristol-based seaweed packaging company Kelpi has won contracts in R&D for high-water barrier solutions for skincare or beauty products, paper/fiber alcohol bottles, Kelpi-coated card/fiber trays, and other ecologically friendly packaging requirements. The company won L’Oreal’s global Beyond Plastic competition in 2023 and the Falling Walls Science Startup award.

Loliware: It is a California-based company that has created the patented SEA Teach™ Resins that can be licensed. Their other product includes seaweed-based straws, which don’t harm the environment. The company aims to reduce plastic pollution and is an eco-warrior.

Other companies, Oceanium, Evoware, and SoluBlue too, are seaweed-derived packaging companies.

Around 159 million tonnes of single-use plastics were produced globally in 2023, of which 43% ended up in oceans/landfills. At these grim numbers, seaweed-based packaging is surely positive. Many startups are in the middle stages and will require a few years to become fully functional. Most manufacturers of bioplastics are looking at business-to-business collaborations. It would be good if these companies started selling their bioplastic bags directly to the public and making them available online.

Benefits of Seaweed Farming

For seaweed packaging purposes, the industry uses macroalgae, unlike microalgae, which is used by the food industry. Seaweed packaging companies work with seaweed farmers/growers at their chosen site and closely look into the process/infrastructure of seaweed farming. Once the seaweed grows to the desired length, it is harvested and taken to the company’s manufacturing site for seaweed packaging production.

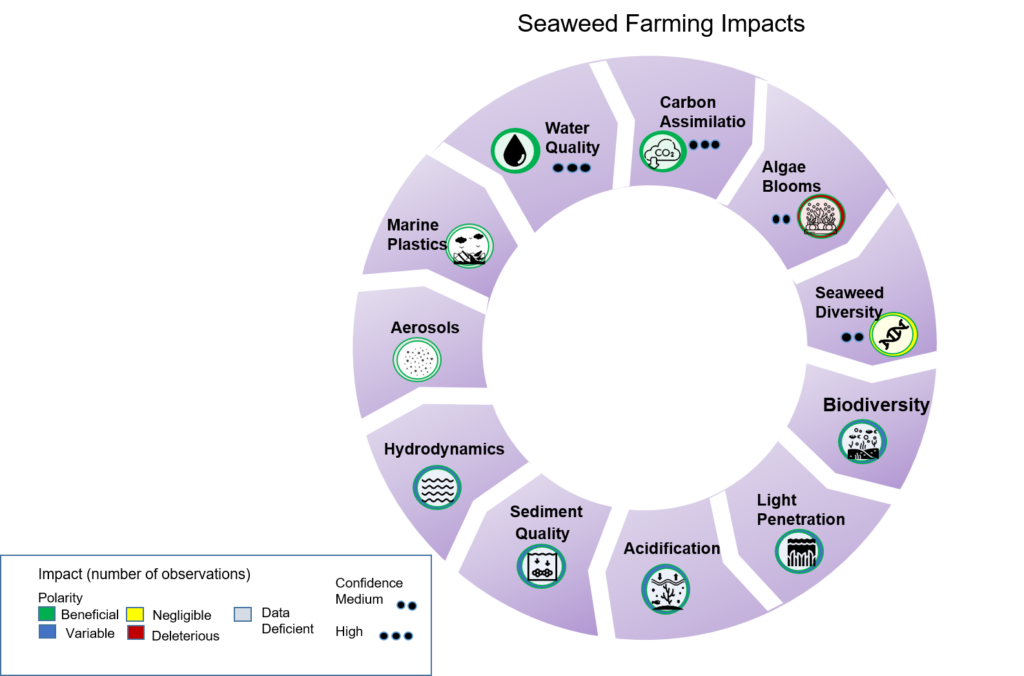

Seaweed used by bio-plastic companies is grown in marine oceans and serves numerous climate restorative purposes like carbon-sequestering, minimizing ocean acidification, ensuring improved marine health/home, and maintaining ocean temperatures/PH. This is possible given that small to medium-level seaweed aquaculture farming is carried out more than industrial farming. Industrial seaweed farming could lead to a lack of oxygen for coral reefs and a misbalance of ocean nutrients/minerals and its intricate ecosystem.

Figure 1: Seaweed farming footprint

Features of Seaweed Based Packaging

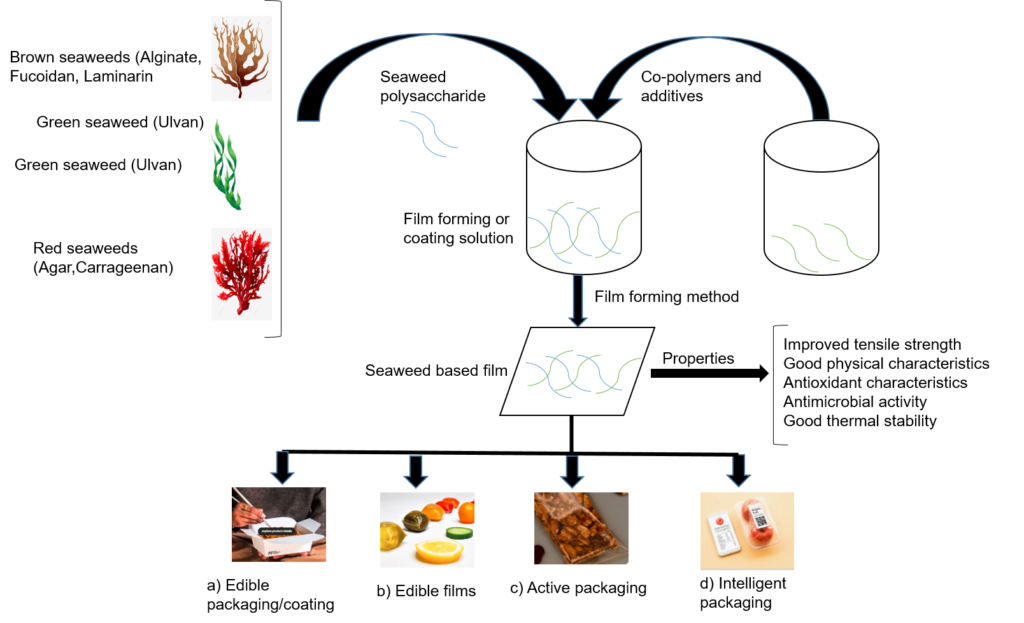

Interestingly, seaweed packaging material is strong, flexible, heat resistant, and transparent, similar to synthetic polymers. Seaweed-derived plastic is 100% biodegradable and ecologically friendly, and some of it is even safe to eat. The end-of-life cycle of bioplastics like those created from seaweed accounts for zero waste, and moreover, upon decomposition, it supplies nutrients to the soil and plants.

Figure 2: Benefits of Seaweed based Food Contact Materials (FCMs)

Precautions Around Seaweed Farming

Seaweed farming needs to be done carefully, keeping in mind the larger ecosystem of the ocean. Macroalgae come in tens of thousands of varieties, each with a specific nucleus and biological makeup specific to the location and nutrient requirement. Excessive commercial seaweed farming can disrupt the natural supply of nutrients like light, oxygen, seaweed asexual overgrowth, and lack of marine fauna diversity. The long-term impact of macroalgae seaweed farming has not been conducted, and it is important that any major adverse changes get reported, recorded, and mitigated.

China, Japan, South Korea, Indonesia, the Philippines, and Malaysia are the largest seaweed-farming countries. Specific data on macroalgae seaweed aquafarming and its impacts, such as the use of plastic, are needed. Seaweeds use up nitrogen and phosphorous; however, taking too much of these growth-forming gases away can be dangerous for benthic life.

Key Seaweed Research Institutes

The most common macroalgae are Chlorophyta (green), Phaeophyta (brown), and Rhodophyta (red). However, there are approx. 10,000 species of macroalgae and various seaweed research institutes are working towards enriching and maintaining seaweed species. Below are a few seaweed R&D institutes.

- Global Seaweed SuperStar: They work towards protecting global wild seaweed species to maintain natural diversity.

- Wageningen University & Research: They work in sustainable seaweed aquaculture technology in the North Sea region.

- University of Gothenburg: Based in Sweden, the group works in areas such as macroalgae ecophysiology, seaweed microbiome, and more.

Conclusion

The largest ecosystem of earth, the oceans, on average, are 3682 meters deep, and the seven seas together have 1.35 billion cubic kilometers of water. The marine gardens are complex ecosystems sustaining ocean life. For precautionary measures, seaweed farming should be avoided on hard substrate sites, as that can introduce invasive sea seaweed. Instead, soft substrates should be preferred. For a genuinely circular society, it is best to reduce the use of both bio-plastics and synthetic plastics simultaneously. It is further imperative that bioplastics-making companies continue to educate their users about the dire effects of microplastics and plastic waste. And that’s why seaweed packaging, smart packaging and other dominant alternatives are finding takers.