Mycotoxins are a diverse group of naturally present and inevasible fungal metabolites that contaminate various agricultural commodities, such as lentils, cereals, grains, etc., at the time of pre or post-harvest. Animals exposed to mycotoxins can suffer from a range of health problems, such as cancer, infertility, sluggish growth, poor performance, and organ failure. Chromatographic methods are the generally used technique used for mycotoxin detection. However, these methods are time-consuming and labor-intensive. So, for quick analysis, frequently used techniques are biosensors, immunoassays like lateral flow immunoassay (LFIA), and enzyme-linked immunosorbent assay (ELISA). Mitigation strategies are roughly classed as physical, chemical, or biological, with differing efficacy against different mycotoxins. Mycotoxins’ complicated structure makes neutralization a serious difficulty for feed additives.

Toxigenic Fungi and Mycotoxin Risks

Toxigenic fungi such as Penicillium, Aspergillus, Alternaria, and Fusarium species produce mycotoxins and secondary metabolites. Mycotoxins are among the most prominent contaminants in food and feed products. Acute or chronic exposure to mycotoxins in feed can cause serious health problems, including impaired immunological function, infertility, vomiting, delayed growth, and gastrointestinal disorders.

According to WHO, some of the common mycotoxins include Deoxynivalenol, T-2, HT-2, Zearalenone, Aflatoxins, Ochratoxin A, and Patulin. Enniatins and Beauvericin are some of the emerging mycotoxins that have also been linked to detrimental effects on pig health, performance, and immunological markers.

Factors such as temperature, humidity, pH, water activity, level of inoculation, and the nature of the substrate influence the growth of mycotoxins and the degree of contamination. Contamination of mycotoxins could occur at any point in the food chain, including harvest, processing, transportation, and storage, resulting in significant waste and social burdens for the food industry. This necessitates urgent development of mycotoxin removal methods to mitigate economic losses and protect consumer health.

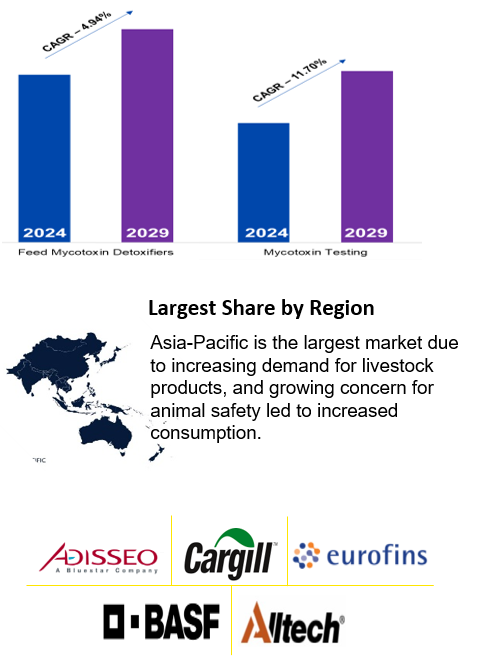

Figure: Key Market Players

Modor Intelligence reports that the Feed Mycotoxin Detoxifiers Market is expected to be worth $2.25B in 2024 and $2.86B by 2029, with a compound annual growth rate (CAGR) of 4.94% between 2024 and 2029. Meanwhile, the worldwide mycotoxin testing market is predicted to grow at a CAGR of 11.7% throughout this time.

Binders have the biggest market share because they efficiently bind mycotoxins, preventing them from entering the bloodstream and protecting animals against mycotoxin exposure. On the other hand, bio-transformers are the fastest-growing market, owing to increased awareness of the significance of limiting mycotoxin absorption while maintaining nutritious characteristics.

Mycotoxins Overview

Aflatoxins

Aspergillus species, particularly Aspergillus flavus and Aspergillus parasiticu produce toxic metabolites called aflatoxins.

- Heat Stability: Relatively stable under normal cooking temperatures; partial degradation occurs at higher temperatures

- Water Solubility: Slightly soluble in water and organic solvents such as ethanol, methanol, acetone, etc.

- Crops Affected: Aflatoxins mainly affect corn, cottonseed, peanuts, and other nuts/seeds.

- Adverse Effects of Aflatoxins:

- Aflatoxins are potential carcinogens, and prolonged exposure could lead to cancer

- At high doses, it can cause immunosuppression and liver damage

- It has been observed that aflatoxins in poultry affect the growth rate, feed efficiency, and egg production. Furthermore, these aflatoxins could be responsible for reduced milk production, immune suppression, and reproductive issues in livestock.

Zearalenone (ZEA)

Zearalenone (ZEA) is a secondary metabolite produced by various Fusarium species, most notably Fusarium graminearum.

- Heat Stability: ZEA is stable up to 150°C and degrades at higher temperatures or under alkaline conditions

- Water Solubility: Insoluble in water but soluble in aqueous alkali and organic solvents, such as ethanol and acetone

- Crops Affected: Corn (major), wheat, sorghum, barley, oats, millets, and rice.

- Effects of ZEA:

- Interacts with estrogen receptors, exerting estrogenic responses

- Pigs are highly sensitive, with females being more susceptible than males

- Causes reproductive health issues in animals and humans, such as vulvovaginitis syndrome, anestrus, and decreased hormone secretion in swine and sows

- Leads to infertility and reduced milk production in cows

- Affects the reproductive tract and hormone-sensitive receptors in poultry, reducing egg production and causing cystic inflammation of the oviduct

Deoxynivalenol (DON)

Deoxynivalenol (DON), also known as vomitoxin, is a secondary metabolite mainly produced by Fusarium graminearum and Fusarium culmorum. It belongs to the type A trichothecene group of mycotoxins.

- Heat Stability: Stable at high temperatures (170˚C to 350˚C). No significant reduction was observed after 30 minutes at 170˚C of treatment.

- Water Solubility: Soluble in water and other organic solvents

- Crops Affected: Cereals such as wheat, barley, oats, rye, and maize. However, rice and sorghum are not affected by the DON much

- Adverse Effects of DON:

- DON affects protein synthesis and mitochondrial activity, resulting in animal immune suppression, immunomodulation, and cytotoxicity

- Causes nervosity, loss of appetite, poor feed efficiency, diarrhea, and vomiting in swine

- Poor feed assimilation results in decreased production, milk quality, and immune disorders in ruminants

- Reduces feed efficiency, shell quality, and egg production in poultry

T-2 and HT-2 Mycotoxins

T-2 toxin and HT-2 toxin are low molecular weight secondary metabolites produced primarily by Fusarium species such as F. sporotrichioides, F. poae, F. armeniacum, and F. langsethiae. They belong to the type A trichothecenes.

- Heat Stability: Cannot be destroyed under normal cooking temperatures (100 to 210°C) within 60 minutes

- Water Solubility: Non-volatile, insoluble in water, and stable at neutral and acidic pH

- Crops Affected: Oats, barley, wheat, maize, and rice, along with cereal-based products and soybeans

- Adverse Effects of T-2 and HT-2:

- Generate reactive oxygen species, increasing lipid peroxidation

- Have immunosuppressive effects, interfering with the inflammatory immune response

- Effects the synthesis of protein, DNA, and RNA by inhibiting peptidyl transferase activity

- In chickens, it causes an inflammatory response in the mouth, leading to necrosis and microbial invasion

Patulin

Patulin (PAT) is a polyketide metabolite produced mainly by Aspergillus, Byssochlamys, and Penicillium species, with Penicillium expansum being a major producer.

- Heat Stability: Stable at temperatures from 105 to 125°C in aqueous solutions with pH 3.5–5.5

- Water Solubility: It is soluble in water and various solvents such as ethanol, methanol, acetone, and ethyl acetate, but slightly soluble in sulfuric acid and benzene

- Crops Affected: It is majorly found in apples and other related fruits

- Adverse Effects of Patulin:

- Covalent bonding with thiol groups in biomolecules leads to negative effects in animals

- Increases lipid peroxidation, suppresses immunity, and disrupts DNA, RNA, and protein production

- In poultry, it leads to an inflammatory response in the mouth, progressing to necrosis and microbial invasion

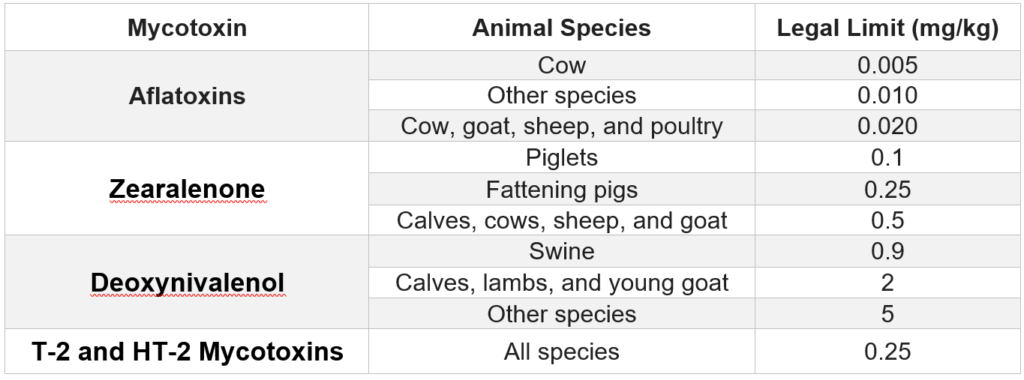

Allowable Limits

Legal limits for major mycotoxins in animal feed as set by the European Commission.

Mycotoxin Detection Methods

Various methods for detecting mycotoxins are available, with chromatographic techniques being predominant. Rapid analysis often employs immunoassays like enzyme-linked immunosorbent assay (ELISA) and lateral flow immunoassay (LFIA). Notably, biosensors are emerging as a valuable tool for identifying mycotoxins in animal feed. Biosensors could be used to rapidly, sensitively, and specifically detect mycotoxins; these also enable on-site, real-time monitoring with user-friendly and cost-effective devices. They enhance food safety by providing accurate and timely analysis.

DSM offers a range of analytical services to assess mycotoxin contamination in feed materials. Spectrum Top® 50 detects and quantifies over 50 mycotoxins, while Spectrum 380® tests for more than 700 mycotoxins and fungal metabolites.

ImagoAI, a food-tech startup, uses artificial intelligence to rapidly detect mycotoxins in corn, such as aflatoxins, deoxynivalenol, fumonisins, and zearalenone.

RIDA®SMART APPquantifies mycotoxins using RIDA®QUICK lateral flow tests with advanced evaluation technology

ExciPlex has developed a diagnostic system for detecting mycotoxins using photochemical techniques. This technology enables real-time quantification of mycotoxins in any feed or feed input.

Mycotoxins Mitigation Methods

The elimination of mycotoxins is crucial for safeguarding both animal and human health. This can be achieved at various stages: in the field during crop production, before the feed is consumed, and after the feed has been ingested by animals. Mycotoxin elimination approaches are broadly defined as physical, chemical, or biological, with the purpose of efficiently removing, destroying or reducing mycotoxins.

Preparing the field before planting is crucial to controlling fungal attack and mycotoxin contamination. This includes various steps like crop rotation, timing the production cycle, and using high-quality seeds.

After planting, healthy plant growth can be achieved by choosing proper field practices and reducing stress on the crops. This basically minimizes fungal growth and mycotoxin production.

It mainly includes the use of fertilizers, appropriate irrigation methods, weed and insect control, chemical control, and biological control. Fertilizers improve plant health and maintain resistance to disease and fungi. Smart fertilizers produced using nanotechnology enhance nutrient absorption, reduce environmental impact, and improve soil health.

Physical Methods

Physical measures are commonly used before feed ingestion to reduce mycotoxins. Irradiation, photocatalysis, cold plasma, ultrasound, and ozone therapy have succeeded against ZEA and DON. T-2 toxin can be mitigated using cold plasma and γ-irradiation. For aflatoxins, methods like irradiation, ozone fumigation, and cold plasma treatment demonstrate significant feasibility for decontamination. These physical approaches offer promising avenues for enhancing food and feed safety by reducing the presence of harmful mycotoxins.

Chemical Methods

Mycotoxin Binders

Mycotoxin binders, also known as feed additives or detoxifying agents, are large-molecular-weight compounds that reduce mycotoxin uptake and distribution to the blood and organs. They reduce the bioavailability of mycotoxin in animals’ intestinal tracts by adsorbing it on their surface. Adsorbents such as Cholestyramine, Magnetic Graphene Oxide, Montmorillonite, and Calcium Bentonite have been observed to be effective against ZEA and DON.

Anpro is a clay-based product that binds deoxynivalenol (DON). With a low inclusion rate and a broad-spectrum mitigation technique, experiments have demonstrated its effectiveness in binding DON. Notably, it does not bind with other dietary elements.

Biological Methods

Enzymatic detoxification

Enzymes could be the one potent strategy as they can degrade or detoxify mycotoxins from feed. Various types of enzymes can be used depending on the specific mycotoxins and substrates. These enzymes can either bind to mycotoxins or degrade them, reducing their bioavailability and absorption in the digestive tract. Some effective enzymes against Zearalenone mycotoxins are lactonase from Gliocladium roseum and esterase from Bacillus pumilus ES-21. Additionally, the engineered detoxification enzyme Fhb7 could potentially target Deoxynivalenol.

Mycofix by BIOMIN is a patented, purified enzyme designed to degrade fumonisins. It employs mechanisms of adsorption, biotransformation, and bio-protection to neutralize mycotoxins. This proven solution effectively combats a range of mycotoxins, including trichothecenes, zearalenone, ochratoxin A, and aflatoxins.

Probiotics detoxification

Probiotics, especially LAB and yeasts like Saccharomyces, remove mycotoxins via surface adsorption or biodegradation. Surface adsorption is fast and reversible, with no chemical modifications. Probiotic strains such as L. rhamnosus, L. amylovorus, L. plantarum, and L. pentosus bind toxins to their cell surfaces and reduce mycotoxin levels. Biodegradation is irreversible but can produce unwanted byproducts. Certain Streptomyces strains successfully digest AFB1 and ZON mycotoxins, whereas probiotic Bacillus licheniformis isolate CFR1 achieves a 94.7% decrease in aflatoxin B1.

ProByn has a range of premium prebiotics and probiotics that have demonstrated exceptional effectiveness, significantly enhancing livestock feeding programs globally. ProByn’s probiotics positively influence the host by optimizing intestinal microbial balance, contributing to improved.

Challenges Faced by Industries

There are several challenges in mycotoxin detection and mitigation, some of which are measured below:

- Despite significant research on biological degradation by microorganisms and enzymes, however, their practical application in food and feed is limited

- Mitigation measures for mycotoxins are complex, with varied doses for different toxins, leading to misunderstandings among animal caregivers

- Laboratory experiments may not precisely mimic industry operations due to the complexity of commercial-scale production

- Most detection techniques are labor and consumable-intensive, susceptible to cross-reactivity and matrix interference, and need basic laboratory skills and equipment

Future Aspects of Feed Additives

Mycotoxin mitigation and detection pose significant challenges for the animal feed industry. Future improvements in mitigation methods will focus on developing single ingredients capable of neutralizing a broad range of mycotoxins without compromising animal health. Regulations regarding mycotoxins are expected to become more stringent in the future, necessitating more potent detection methods. The industry will likely see the emergence of non-invasive, rapid, application-based, and easy-to-use technologies, simplifying the process of ensuring feed safety.