Sustainable Binders for Thermal Insulation

In a world where every sector is trying to contribute to achieving sustainability through scientific research, innovations, and technological advancements, the construction industry is treading hand-in-hand with the vision for green building materials. Sustainable binders for thermal insulation are rising at the forefront as crucial components that aid the environment and enhance the quality of structures while staying true to nature’s requirements. Notably, conventional binders are drawn from petrochemical products that contribute to carbon emissions due to non-biodegradable manufacturing processes.

Why are Binders Important in Thermal Insulation?

Binders precisely work as adhesive agents that bind insulating materials tightly, ensuring long-term performance and structural prowess. Conversely, conventional binders are mostly petroleum-based, potentially raising the hazards of immense carbon footprints and the spread of VOCs (volatile organic compounds) in the environment. Meanwhile, sustainable binders are extracted through natural processes that use renewable or recycled resources, significantly reducing environmental impact.

Binders for Thermal Insulation: Technical Overview

Binders are an important cog in thermal insulation that bind insulating particles or fibers, offering improved performance and standard structural integrity. They are expected to stand firm during all conditions and situations, including environmental changes, degradation, humidity, and fluctuating temperatures. Here are the technical aspects:

- Durability: The binders demonstrate temperature fluctuation resistance and long-lasting stability for a bigger and better insulation effect.

- Moisture and Water Resistance: The hydrophobic-induced properties can prevent moisture and act as water resistance. However, this may lead to fungus formation while compromising insulation performance.

- Fire Resistance: The role of fire-resistant binders is important during industrial and construction applications as they offer optimum safety

- Thermal Conductivity: The thermal conductivity must be contributed by binders to the overall insulation material. Meanwhile, for efficient thermal insulation, lower thermal conductivity is preferable.

Traditional binders have a detrimental environmental impact because they are derived from fossil fuels, such as petroleum-based chemicals. Thus, there is a significant move toward biodegradable, natural, renewable, and environmentally friendly binders. Some of the top sustainable binders are extracted from starch, cellulose, protein-based sources, and lignin. Bio-based binders produce reduced carbon emissions and lower environmental footprints during application and production.

Types of Sustainable Binders for Thermal Insulation

As the demand for viable alternatives for binders has increased, several eco-friendly and bio-based binders have witnessed spiked attention. Find below a few of them:-

Starch-Based Binders

It is a carbohydrate, which is renewable and biodegradable as it is drawn from plants. Moreover, it comes with low toxicity. Furthermore, starch-based binders can be used in conjunction with or simultaneously with other additives to enhance durability and water resistance.

- Applications: It is primarily used in fiber insulation and rigid foam boards

- Properties: Effective bonding strength, biodegradable and renewable

- Issues: When compared to synthetic binders it offers lower durability and less moisture resistance

Lignin-Based Binders

It has been considered one of the most sought-after sustainable binders. A natural polymer extracted from plants, it has also been extensively researched. These binders play a crucial role in thermal stability and improving fire resistance. Moreover, they are environmentally friendly and cost-effective for users.

- Applications: It is primarily deployed in bio-composite panels and fiber insulation

- Properties: It offers resistance to UV degradation, thermal stability, and high mechanical strength

- Issues: There’s limited compatibility with a few substrates and variability in composition based on its source

Polymeric Binders from Bio-Based Sources

Synthetic polymers, including PLA (polylactic acid), are drawn from bio-based feedstocks following advancements that have triggered development in the field. Importantly, these polymers are renewable and biodegradable, offering the flexibility and durability of synthetic binders.

- Applications: It is extensively applicable in fiber insulation and foam

- Properties: It is flexible, durable, and eco-friendly

- Issues: The cost is higher and can’t be scaled beyond a point

Cellulose-Based Binders

It is a structural component of renewable and biodegradable plant cell walls. Once modified chemically, it offers great thermal capabilities and binding strength.

- Properties: It is recyclable, renewable, and biodegradable, offering good thermal insulation properties

- Applications: It is mostly applied in batt insulation or loose-fill

- Issues: Lower fire resistance compared to synthetic binders

Technological Advancements and Futuristic Methodology

As the demand is rising for sustainable binders, innovation, and inventions have also increased in polymer technology and material science. New avenues are mushrooming following continuous research and technological advancements. Some of them are mentioned below:-

a) Hybrid Binder Systems

They combine bio-based and synthetic binders to multiply their advantages. The primary aim of these systems is to reduce carbon emissions while ensuring high-performance quality. Hybrid binders may include materials derived from waste, adhering to the principle of a sustainable or circular economy.

b) Additive Manufacturing and 3D printing

Additive manufacturing is navigating the path from custom insulation products coupled with sustainable binders. Moreover, industries and businesses can optimize shapes and produce complex structures using bio-based binders in 3D printing; offering improved minimal waste and exceptional thermal performances.

c) Nanotechnology

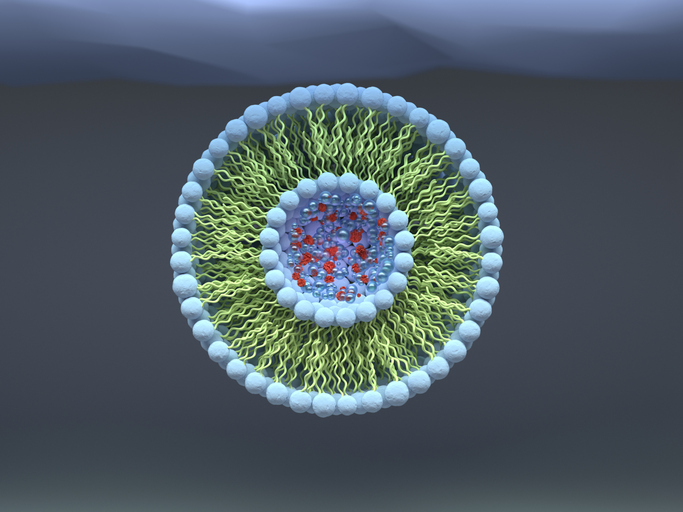

Nanomaterials can enhance the mechanical and thermal properties of bio-based binders. Currently, cellulose nanofibers are used to improve the performance of starch-based binders, influencing the creation of explicitly bio-based composites of high performance.

d) Self-Healing Materials

In regions that have harsh environmental conditions and improper climatic situations, self-healing binders can prove to be a game changer for improving thermal insulation performance and longevity. Researchers and scientists are working on self-healing materials that can do self-repairing upon exposure to heat and other stimuli.

Sustainable Binders Adoption

The benefits of sustainable binders are not hidden from industries, and they are increasingly using them in the automotive, construction, and packaging domains by recognizing potential. As renowned companies and industry leaders are willingly accepting bio-based solutions for thermal insulations, the cost is escalating swiftly. Here are the reasons fueling the industrial embrace:

- Sustainability Targets: Several corporates are fixing their aim to reduce carbon emissions through sustainable binders as they assist them in achieving their goals.

- Consumer Demand: Rising awareness and increasing demand for green building materials have pushed industries to incorporate sustainable binders.

- Economic Benefits: Sustainability practices often include discounts, tax benefits, and subsidies from NGOs, environmental organizations, and governments.

- Environmental Rules: The restrictions imposed by several organizations and governments in different countries on VOCs (volatile organic compounds) and immense emissions are forcing industries to go with eco-friendly binders.

Giant insulation manufacturers, including Knauf Insulation, Owens Corning, and Saint Gobain, are investing in sustainable binders to boost their insulation products, which directs toward an upward trend. Notably, Knauf Insulation has produced a formaldehyde-free binder, ECOSE® Technology, created from renewable bio-based materials.

Market Growth for Sustainable Binders

The global market growth for sustainable binders looks promising following the rising awareness, increasing demand, regulatory requirements, and environmental issues in different industries. Here are the trends:

The sustainable insulation material market is slated to grow at a CAGR of 10 percent by 2030, supported by eco-friendly binders. Binders extracted from starch and lignin can make an impact due to their lower cost and abundant availability. The Asia-Pacific market region is at the cusp of drawing the highest growth rate, following the focus on a sustainable development roadmap chalked out by governments and industries. However, North America and Europe are going strong in the current scenario, driven by green building incentives and strict laws on environmental safety.

Investment Opportunities and Growth Prospects

As the market commands sustainable insulation solutions, the opportunities for businesses and investors in binder technologies can be exciting and worth profits. Companies looking to attract public and private investments along with venture capital should stay focused on the application and development of bio-binders. The burgeoning interest of companies enveloped with energy efficiency and a larger commitment to sustainable means reflects on the green sector. For quick and scalable growth, companies are registering partnerships with insulation manufacturers and bio-based material suppliers. Moreover, collaborating with research institutions can help companies access innovative binder technology that can be valuable.

Major Challenges for Sustainable Binders

Sustainable binders for thermal insulation may seem one of the greatest prospects for industries and the environment; however, they are not free from challenges. Thus, they need to be considered and addressed accordingly:

- Supply Chain Complexity: Fetching bio-based materials seamlessly can be difficult due to regulatory issues, agricultural conditions, and supply fluctuations.

- Scalability: Due to the limitations of raw materials and huge costs, there’s always a hindrance to growth in the production processes.

- Performance Limitations: The durability and stability of some bio-based binders, like protein-based and starch-based binders, are lesser compared to thermal to synthetic counterparts.

Conclusion

Adoption and acceptance of sustainability and innovation have become the pedigree for continuous growth for any industry, and the standard suits sustainable binders in thermal insulation, too, due to the energy-efficient and eco-friendly materials. As the world is moving toward green and environmental formulation, compelled by global warming and the deteriorating health of the Earth, sustainable binders are a welcoming step backed by the demand of common people and stringent rules by governments. Investors, companies, industries, and stakeholders are realizing the strength of transformation from non-sustainable to sustainable binders and working in tandem in partnerships and collaborations to grab the opportunity to scale and expand in the market by innovating and manufacturing hybrid materials and bio-based binders. It’s noticeable that cost-reduction strategies and supply chain integration can be pivotal in overcoming challenges in the market for thermal insulation.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.