Evolution of 3D to 5D Printing in the Medical Industry

In a new era of innovative development, the medical devices industry is experiencing revolutionary changes catalyzed by the advent of 5D printing technologies, which are capable of creating objects of any complexity more durable and accurate than regular models made using advanced conventional 3D printing techniques; one example would be healthcare where various applications have been discovered as potential uses for this emerging technology such as material science, drug delivery systems or bio-medical research instead of just focusing on designing prostheses like before argued. The idea of 4D printing was introduced in 2014, while American universities introduced the concept of 5D printing in 2016.

The relevance of this technology in modern healthcare is pivotal, given the numerous advantages it provides to improved individual care, better therapeutic results, and the progression of medical technology. The article deals with the transformation from 3D printing into 5D printing mode within the context of medical devices. Further, some of the main shortcomings that come with such progress in the future have been indicated.

How 4D/5D Printing is Different from 3D Printing?

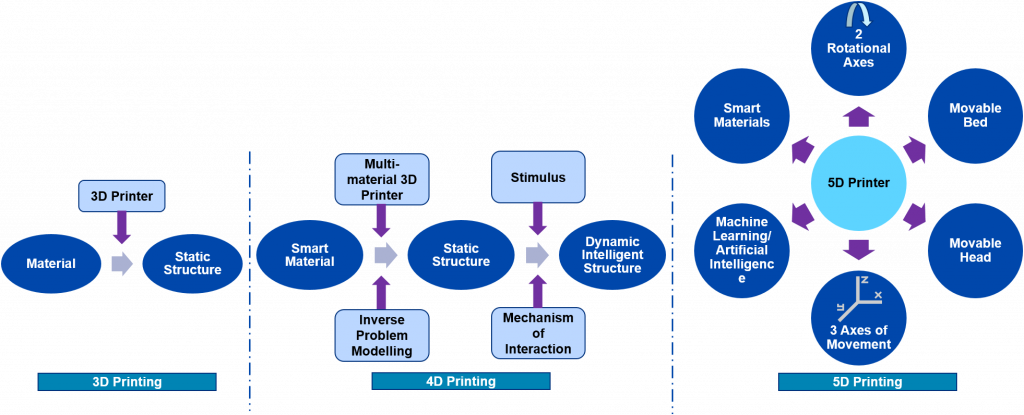

Figure 1: Comparison of 3D, 4D and 5D Printing

4D printing is a cutting-edge method in additive manufacturing that creates structures with pre-programmed changes in shape, property, or functionality when exposed to specific stimuli. It comprises a fourth dimension time to 3D printing to describe objects that can self-transform over time after printing. 4D-printed objects allow self-repair, self-assembly, and multi-functionality features.

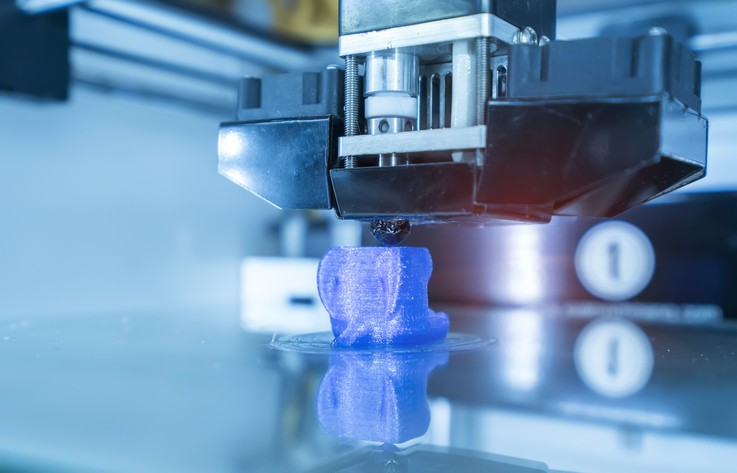

3D printing or additive manufacturing is built on the x, y, and z-axis and involves assembling a three-dimensional object from a CAD model.

The main dissimilarity between 3D printing and 5D printing is that 5D printing manufactures a stronger portion with a curved layer, whereas 3D printing creates a portion with a flat surface; nevertheless, the manufacturing methods are similar. However, 4D printing is different from these two technologies. It uses different varieties of programmable materials that can change their shape and function with the increase in the human body’s temperature over time. The materials produced are called smart materials as they have thermo-mechanical properties.

Artificial parts, such as implants as strong as the original human part and with curved surfaces, are needed in the medical domain. 5D printing technology can be used to print objects that are 3 to 5 times stronger than a 3D-printed object.

5D Printing Trends Shaping the Future of the Medical Industry

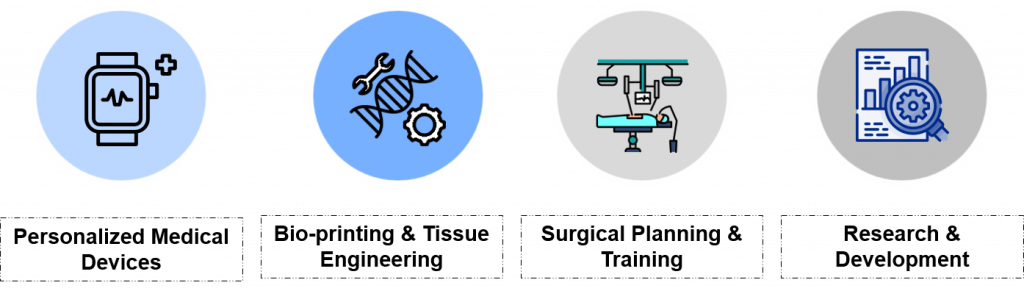

In the healthcare industry, 5D printing technology opens the door to more advanced medical procedures and patient care, including dental care, orthopedic surgery, prostheses, and surgical equipment. Some of the trends are:

Figure 2: Trends shaping the future of the medical industry

- Personalized Medical Devices: One of the most exciting applications of 5D printing in the medical field is developing customized medical equipment such as implants, prosthetics, and anatomical models with high strength. Using computer-aided design (CAD) data, it can design any curved tools/equipment as per the patient’s need.

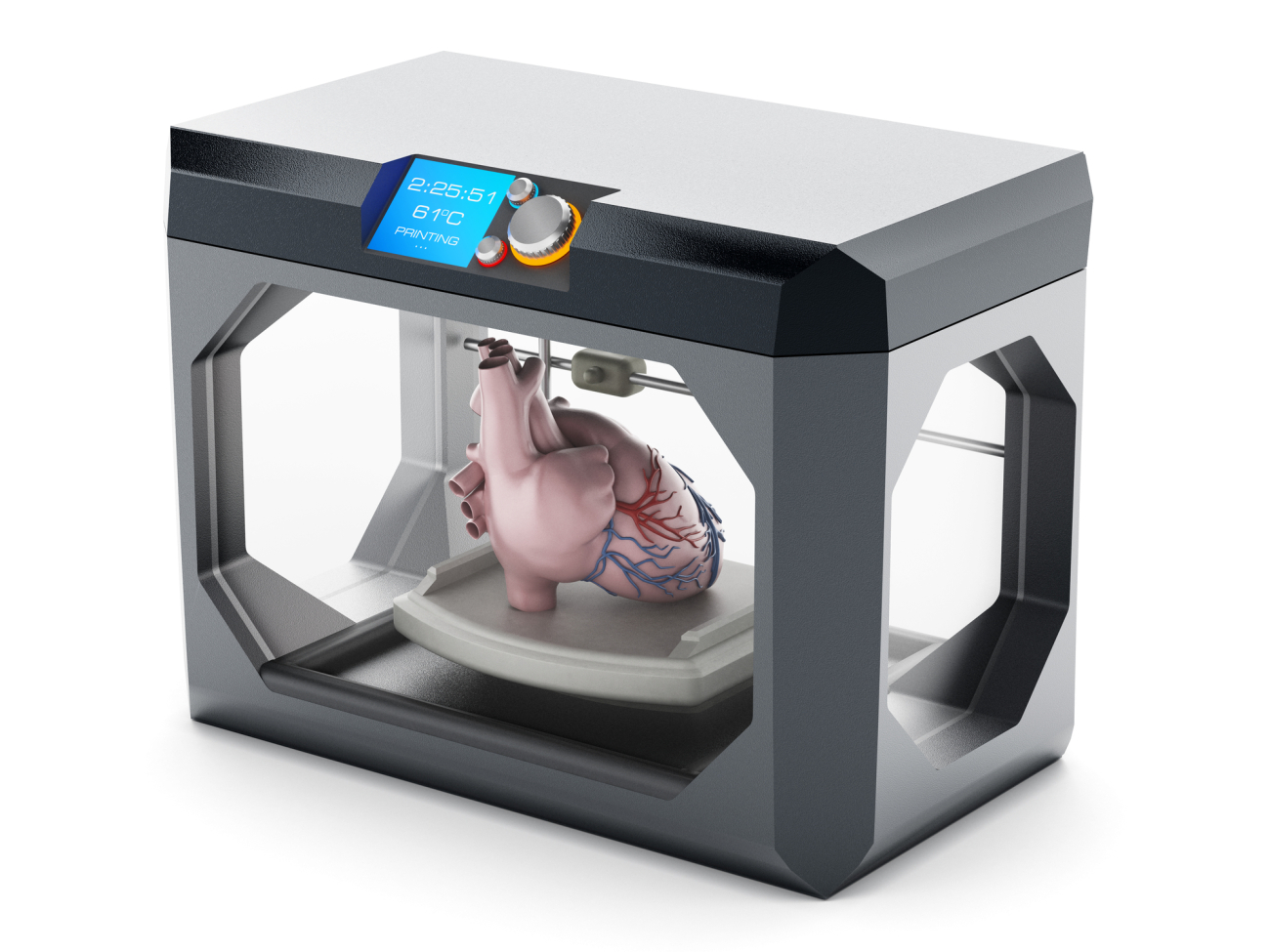

- Bio-printing and Tissue Engineering: 5D printing is making significant changes to bio-printing, thereby stating that it permits the production of complicated tissue constructions with spatially controlled architectures juxtaposed next to biochemically gradient areas. Incorporating various types of cells within the printed constructs, including growth factors and biomechanics, enhances quick recovery and other health purposes. Scientists are putting efforts into applying the five-dimensional printing techniques to develop vascularized tissues, organoids, and scaffolds meant for regeneration.

- Surgical Planning and Training: 3D printing technology is the current technology for producing models used to plan surgeries as well as implants implanted inside the human body. It also helps to produce personalized patient care devices, kits for surgery, and instruments that are not standard. This unique technology allows the creation of surgical instruments from various design software programs alongside different tools for analysis and synthesis thanks to its application. Therefore, surgeons can use 5D printed models to see complex anatomical structures, perform surgical procedures, and develop optimal surgical strategies for individual patients.

- Research and Development: 5D printing facilitates advanced tools for the prototyping and testing of medical devices and therapeutic interventions for researchers.

In the future, 5D printing will allow self-assembling materials to be printed with greater strength. It will become an important technology to print smart curved medical parts that can change shape with time. Compared to traditional 3D printing, it saves about 25% of the material. It can design advanced tools, devices, implants, medical pipes, valves, and prosthetics with improved strength per patient requirements. This technology can potentially become essential for dentistry, orthopedics, prosthetics, and surgical equipment.

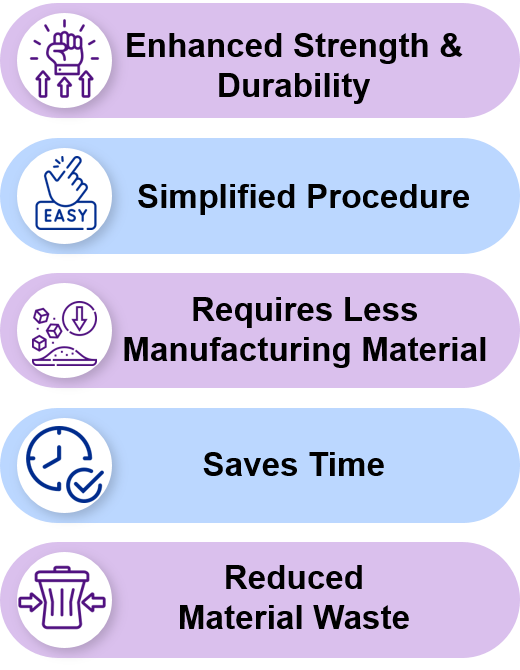

Benefits of 5D Printing Technology

The benefits of 5D printing collectively contribute to advancing healthcare by providing more effective, customized, and user-friendly solutions:

Figure 3: Benefits of 5D Printing Technology

- Simplified Procedure: Requires fewer supports to print intricate and complex structures, which reduces the steps of manufacturing, making it a simple process to carry out

- Requires Less Manufacturing Material: Enables printing at a variety of angles, which reduces the need for infill and supports, therefore reducing the amount of manufacturing material dramatically

- Saves Time: Fewer supports are required to print intricate and complex models, which eventually saves time

- Enhanced Strength & Durability: Able to create durable curved layers/ complex structures with good strength

- Reduced Material Waste: It is possible to manufacture a complex structure with 25% less material

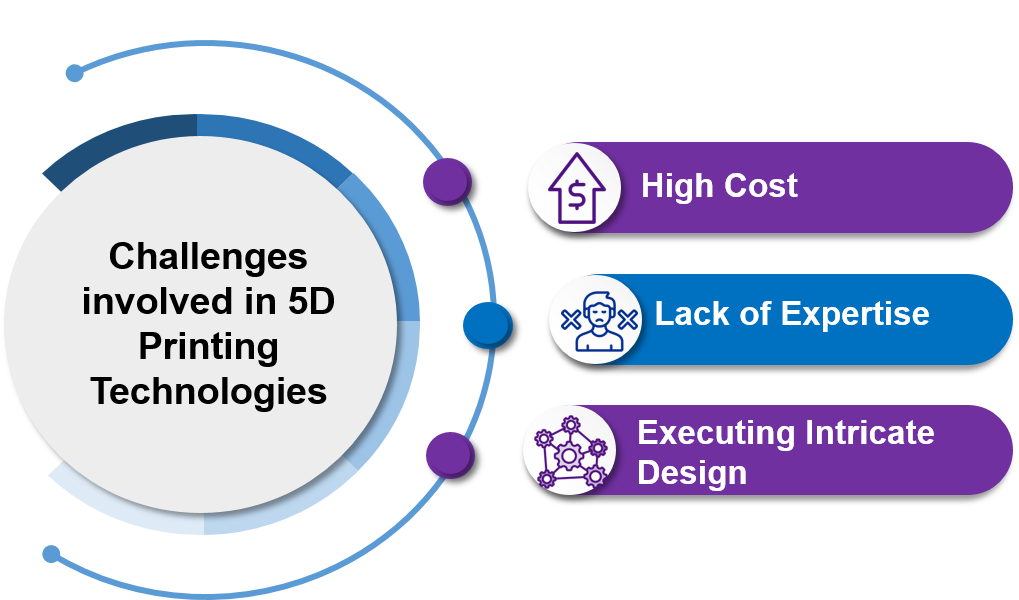

Challenges Involved in 5D Printing Technologies

Figure 4: Challenges involved in 5D Printing Technologies

Several of the problems and difficulties need to be solved to successfully implement and adopt 4D/5D printing technologies in the medical devices industry. Some of the key challenges include:

- High Cost: Costs of the extra two axes essential for the printing bed

- Lack of Expertise: There is a lack of skilled resources who are skilled in operating and maintaining the machine. Also, it is worth mentioning that few people know about this cutting-edge technology because only a few technologists are educated enough to have a working knowledge of such recently introduced technological advancements in this field.

- Executing Intricate Design: Developing intricate structures and managing the additional axes in 5D printing needs a higher level of expertise

Conclusion

5D printing is an impending manufacturing technology, creating intricate, robust, structured products that are much stronger and more precise than conventional 3D printing methods. It involves subtractive and additive processes and complex axis movements incorporated during production. William Yerazunisto proposed the idea to strengthen the already existing 3D-printed parts. Unlike 3D printing, where three axes are used, 5D printing technologies use a five-axis printing technique, which produces objects in multiple dimensions. This advanced technology produces parts with a curved layer and improved strength. The print head and the printable object have five degrees of freedom, and the print part moves while the printer head prints. It has various applications in the healthcare sector and other sectors such as food, automobile, etc.

5D printing is a promising and emerging new frontier in the medical industry, producing incredibly intricate and curved structures. It is a hybrid technology that involves additive and subtractive manufacturing techniques using three movement axes (X, Y, and Z) and two rotational axes. As technology advances, it offers significant advantages in terms of strength and complexity over 3D and 4D printing technologies. However, high-cost problems and lack of expertise must be carefully considered when integrating these novel solutions into standard medical device manufacturing procedures.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.