E-Waste Recycling: Challenges and Country Wide Strategies

Every year, around 40 to 50 million tons of E-waste is generated, which accounts for 3-4% of total global waste. E-waste is any discarded electronic waste such as laptops, smartphones, televisions, electrical appliances, etc. This E-waste is harmful to the environment, and its exposure also harms humans. E-waste contains many hazardous substances, such as cadmium, mercury, and lead. These toxic substances can cause UV radiation, and exposure can lead to soil and water infertility, etc. It is necessary to eradicate this waste properly and be aware of the consequences of these substances. The focus has now shifted to combating electronic waste, and various countries are adopting various rules, proposals, and guidelines to tackle this waste. The most important way to combat this is by recycling e-waste.

Market Overview

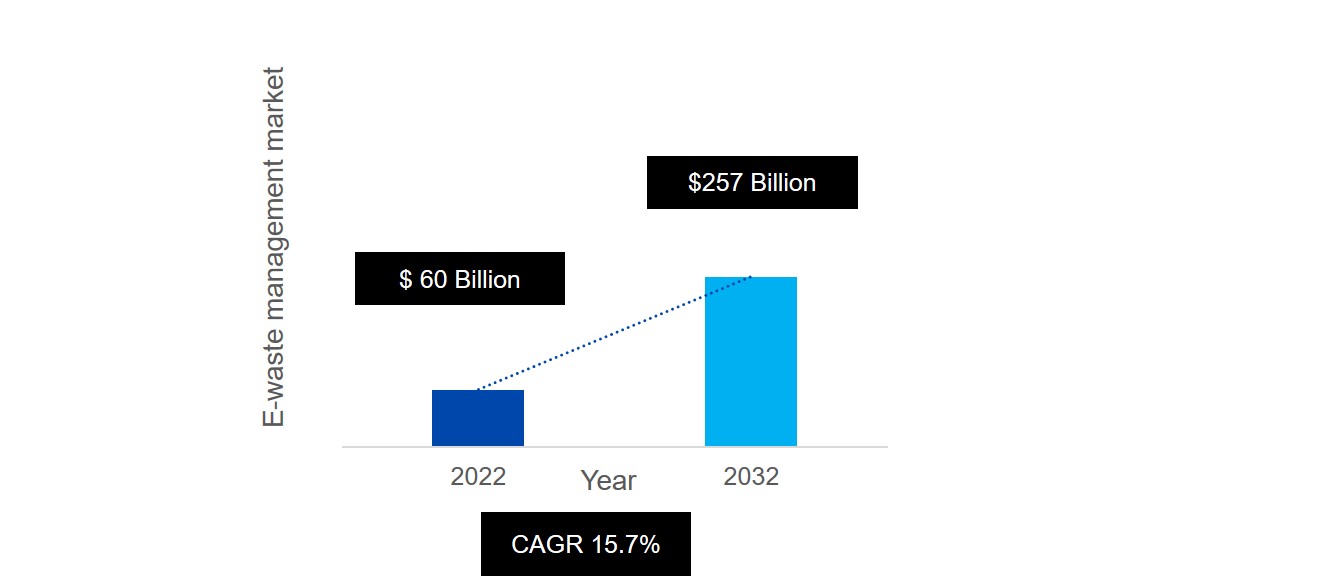

E-waste recycling offers refurbishment, recycling, and data security of electronic products that have a potential growth shortly. Several organizations, tech giants, and entrepreneurs foresaw the hazardous effects and opportunities in e-waste recycling and worked for years to turn it into a full-fledged industry. The global e-waste recycling market’s total valuation was approx. $60 billion in 2022 is expected to grow to $257 billion in 2032 at a CAGR of 15.7%.

Figure: E-waste recycling market status

Importance of E-waste Recycling

Hazardous to Humans and the Environment

Electronic waste needs to be kept away from landfill disposal. These materials contain harmful components such as cadmium, chromium, mercury, lead, and zinc. Each of these components has a harmful effect directly or indirectly on the environment. The amount of waste generated by electronics is directly proportional to the demand for electronics. In the current scenario, since more than half of the country is liable for these products, the amount of waste generated is also high.

Recycling will Decrease the Demand for Raw Materials

Many electronic components require non-renewable resources such as gold, silver, and copper, which must be mined. The mining and procurement costs of components are also high. By recycling E-waste, the components extracted from the waste can be modified, recycled, and reused for some other products. This will save the cost of mining new components and reduce the amount of waste generated.

Major Challenges

Product Complexity

Electronic products are complex machines with hundreds of minute parts. It is difficult to separate and sort them according to their constituting materials. The process involves dismantling, shredding, separating fine materials, sorting materials, and removing glass and plastics. The heterogeneous nature of these products makes every stage of separation resource—and capital-intensive. Sometimes, even multiple separation processes are not enough to separate every small thing from each other.

Cost

One of the most important barriers is the cost involved in e-waste recycling. The recycling process requires specialized technologies, equipment, and facilities, which can be quite costly. Companies’ main reason for refraining from setting up e-waste recycling programs is cost. It can be expensive to recycle e-waste properly, so many people just dispose of it in any trash.

Lack of Awareness

One should be aware of the differentiation of products under different disposals. People often dispose of their electronic waste in the trash, which leads to the major disposal of e-waste in landfills. This is why it becomes necessary to be aware of the recycling processes and the steps involved in them.

Lower Process Efficiency

Due to the high rate of production and design complexity of these products, process efficiency is an obvious and inherent challenge. Recycling companies still struggle to find affordable technologies to sort large volumes of e-waste. Apart from cost, multiple procedures and requirements further add downtime to the overall process, which is a big setback for recycling companies.

Separating Hazardous Materials

Some electronic devices contain hazardous materials like lead and mercury, which makes recycling them more difficult and dangerous. The main challenge is to separate all these hazardous substances from a single product. As it involves various substances, the steps to extract them also vary. These extraction and separation involve advanced technologies. This is why many recycling companies refrain from taking on e-waste projects due to the risk involved.

Contamination of Materials

Lower process efficiency and high complexity of electronics result in contamination of materials. Most e-waste buyers are revising policies to minimize losses due to contaminated materials. They are attempting to set higher standards for material purity, adding more pressure on Material Recovery Facilities (MRFs) to yield cleaner products. It makes the processes more stringent and leaves less scope for material mixing. Due to informal e-waste recycling activities, children and pregnant women, being highly vulnerable, are often trapped by this hazardous exposure of materials, e.g., Mercury, when released into the environment, can cause placenta and breastmilk contamination in pregnant women.

Country Wide Adoptions

The United States of America

The National Strategy for Electronics for Electronics Stewardship report has been developed. This report includes the details of the federal government’s plan, which is 1) invent a greener design of electronics, 2) increase domestic recycling, and 3) decrease exports of harmful e-waste.

China

China has adopted the Extended Producer Responsibility (EPR) scheme to address the current environmental impact. This scheme provides incentives to manufacturers and producers of electronic items. Electronic manufacturers receive subsidies for collecting and disposing of their E-waste products or outsourcing their work to others. Every disposal procedure must meet environmental standards. For example, the rates for air conditioners were raised from CNY35 to CNY 130. The rates for Television sets and microcomputers were reduced from CNY 85 to CNY 60.

India

India has adopted Extended Producer Responsibility (EPR), which applies to manufacturers, refurbished, dismantlers, producers, and recyclers of electronic products. This program covers every product that runs on electricity. The producers would be assigned annual recycling targets of 60-80 percent of the goods they produced and sold.

Europe

The European Commission has adopted a new proposal focusing on the repair of goods. This would result in consumer savings and support the European Green Deal.

Conclusion

With the growing demand for electronic products, raising awareness about disposing of these electronic components also becomes equally necessary. Many nations are developing new programs and strategies worldwide for E-waste management. At an individual level, the steps taken also play an important role in the whole disposal cycle. The top companies involved in e-waste recycling and management are MBA Polymers, Electronic Recyclers International, Inc., Umicore, and others.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.