Non-halogenated or halogen-free fire retardants (HFFRs) have emerged as a plausible solution to conventional fire retardants’ environmental and health challenges. As more countries regulate the phasing out of halogenated flame retardants, investments in HFFRs are increasing exponentially. For instance, the recent ban on brominated flame retardants and PFAs in the U.S. increased FRX’s sales by 400 MM USD in the last 1.5 years. Nevertheless, innovative HFFRs have their own challenges that demand acknowledgment and attention from several aspects. Here is a short effort to summarize the aspects relative to the latest innovations and developments in this domain:

Understanding The Need For Halogen-Free Flame Retardants

Halogen-free flame retardants are a step up from halogen-based flame retardants in multiple ways. Researchers and industry professionals acknowledged the detrimental effects of bromine and chlorine-based flame retardants in the last decade. This realization created a need for halogen-free alternatives. Products with brominated flame retardants showed bioaccumulation persistence and toxicity profiles. They are a significant obstacle in the circular economy as the halogenated flame retardant molecules showcase POPs characteristics when discarded. Evidence suggests toxic flame retardants in wildlife, water bodies, birds, soil microbes, and humans. The adverse effects extend to hormonal disruptions and developmental, neurological, reproductive, immunological, and behavioral effects. The expansion of the halogen-free flame retardant additives market is significant as the EU and US governments impose stringent bans on the use of BFRs like decabromophenylether in electronics and electrical products. Industry experts anticipate that the halogen-free flame retardant additives market will reach its full potential in the coming years.

Classification Of HFFRs

On a broad basis, we can categorize halogen-free flame retardants into five major categories.

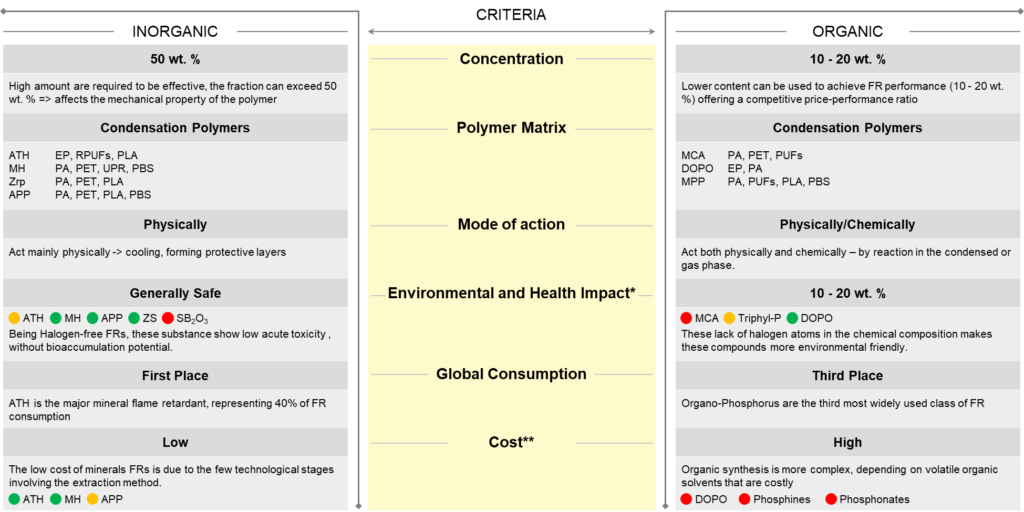

- Phosphorous-based flame retardants: The phosphorus-based FRs include inorganic and organic substances ranging from red phosphorus to phosphinates, phophonates, phosphate esters, etc. As these substances come in contact with heat, they release phosphoric acid that interrupts the combustion process by forming char. This class of HFFRs has wide applications in several manufacturing industries, including textiles, plastics, coatings, polyurethane foams, etc.

- Nitrogen-based flame retardants: These include homologues, aka melamine derivatives. They combat combustion in multiple ways, like char formation, release of inert nitrogen, and synergistic effects in combination with nitrogen and phosphorus. These products are widely used in electronics, furniture foams, and insulation.

Image 1: Features of Different Halogen-Free Flame Retardants

Further Classifications of HFFRs

- Metal Oxides: Inorganic flame retardants, specifically magnesium and aluminum hydroxides, find widespread usage. Among the two options, many industries prefer aluminum trihydroxide (ATH) due to its cost-effectiveness and high-temperature stability. Magnesium hydroxide is a step up from it as it remains stable up to temperatures as high as 300 degrees centigrade. It is highly suitable for polymers processed under high operating temperatures. The most common use cases of metal-oxide-based FRs include paints, textiles, wires, cables, rubbers, and adhesives. These compounds release water in the presence of heat, which dilutes the flame and cools down the temperature.

- Nanocomposites: Carbon nanoclays and nanotubes have shown effective results when used as a co-additive in specific FR applications. When used in polymer matrices, these reduce the loading prerequisites for other FRs and improve overall mechanical, heat-distortion temperatures, and thermal stability. They also decrease the material’s vapor permeability and flammability.

- Intumescent Flame Retardants: Intumescence is the combination of foaming and charring on the surface of the polymer, which secures the underlying material from burning. Processes requiring high levels of flame retardancy utilize intumescent FRs. They can combat the flame without toxicity and inefficiency. Based on their flame resistance, the IFRs are categorized into soft and hard classifications. These are excellent for exterior steel fireproofing, plastic pipe firestops, etc.

Major Challenges With HFFRs

- The Dilemma of Defining Halogen-Free: A substance that is halogen-free does not contain any elements from Group 7, including chlorine, bromine, fluorine, iodine, and Astatine. This characteristic ensures the absence of these halogens in the substance. In cases where the underlying product already includes a halogen, companies can add HFFR reactively or additively to enhance its flame-retardant properties. For instance, in electronic products, people are not paying much attention to the abundant use of fluorine in fluxes for soldering purposes. Similarly, PVC extensively utilizes chlorine to enhance longevity in automobile applications such as coatings, linings, carpet back lining, and shock absorption. If an HFFR is added to these parts for enhanced safety, would the resulting end product be halogenated or halogen-free?

- High Costs: Most alternatives that have come to light as halogenated flame retardants aren’t economical. From the pre-mentioned point, a normal present-day car has 18 kgs of PVC, which is considered highly important in the automobile industry for its economical nature, flexibility, and flame retardancy. If it were to be replaced or banned by regulatory authorities, the automotive industry would face grave consequences.

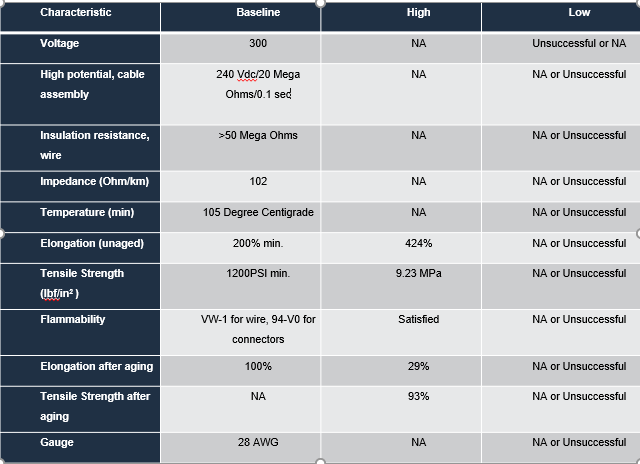

- Performance Trade-off: HFFRs still trail their counterparts in performance. For example, halogen-free ribbon cables in automobiles pose electrical, mechanical, and physical challenges. A study revealed that maintaining the thin and wide shape of ribbon cables was difficult, as efforts were made to bring uniformity to insulation without any electrical spark test faults. Below, we provide a summary of these faults.

Image 2: Halogen-Free ribbon cable characteristics and final results

Additional challenges

- Fear of Regrettable Substitution: Right now, the core focus is on finding alternatives to halogenated flame retardants and less focus on the environmental, health, and overall implications of these new alternatives. For example, phosphorus-based flame retardants are explosive and neurotoxic in nature. And even in terms of efficiency, they lag behind their bromine-based counterparts. It is a must to consider these replacements from all aspects before making them the core of the global flame retardants market.

- Large Quantities Required: The biggest issue is adding HFFRs to products in large quantities. This compromises the performance and quality of the underlying product while aiming to achieve the desired flame-retardant effect. For instance, flame retardant polymers require the use of aluminum trihydrate (ATH) at levels of 40-65 wt%, which compromises the mechanical aspects of the compounded products.

The absence of halogen in soldering pastes causes solder paste makers to face significant challenges, resulting in grasping and head-in-pillow effects. This absence will leave a massive impact on the electronics industry.

Conclusion

The halogen-free fire retardant market holds immense promise, but success requires careful navigation and informed decisions. Understanding the limitations and health risks of alternative products like nitrogen, phosphorus, and nanocomposites is key to effectively implementing them. Extensive research and development will unlock their potential, establishing a solid scientific foundation. Prioritizing long-term monitoring, rigorous testing, and standardization will ensure ethical considerations and informed choices that balance sustainability and economic viability. Also, a holistic approach allows the market to advance confidently, building a sustainable solution for fire safety challenges.