Plastics are an essential part of automobiles, and they are used in dashboards, bumpers, splash guards, handles, and engine covers to make vehicles fuel-efficient and lightweight. However, at the end of their life cycle, plastics are hard to dispose of, creating an environmental hazard. One solution to the piling plastic problem is the use of bioplastics in the automobile industry. We have already published an article on the benefits of the use of bioplastics in automobile interiors. This article ponders deeply on CO2 bioplastics in the automotive industry.

To attain sustainability goals, the automobile industry is stepping up its game by embracing bioplastics in various applications. By incorporating bioplastics in these application areas, automakers can create lightweight, durable, and energy-efficient components.

Bioplastics are made from renewable biomass sources such as vegetable fats and oils, corn starch, straw, woodchips, sawdust, recycled food waste, etc. The availability of these materials is limited and currently defined for other application areas. A steady supply of renewable biomass sources is needed to scale up bioplastic production. Procurement of these materials puts additional pressure on the farming industry, leading to indirect pollution.

Bioplastics are developed and used to meet sustainability goals. However, its production leads to indirect CO2 emission due to the need to supply additional source material for bioplastic production.

Wouldn’t it be great if CO2 itself could be converted to bioplastics? This would help attain sustainability in a real sense, as it would reduce CO2 emissions and capture and process the CO2 emitted from other industries into bioplastics. Recently, scientists have developed various processes to convert captured CO2 into bioplastics, which can be deployed for various applications. Also, these bioplastics will disrupt the automobile plastic market if the scalability issue gets solved.

Innovations in Carbon Dioxide-based Bioplastics for Automobile

Carbon dioxide-based bioplastics have applications in automobile interiors, car bodies, and tires. Below are the innovations related to carbon dioxide-based bioplastics for the Automobile industry:

Carbon Dioxide-based Sustainable Tyres

Toyo Tire Corporation developed a new catalyst to convert carbon dioxide into butadiene rubber with high yield without using expensive precious metals. It was developed in collaboration with the University of Toyama. The process involves the conversion of CO2 to ethanol by the new catalyst and further converting ethanol to butadiene by zeolite catalyst.

Renewable Bioplastics from CO2

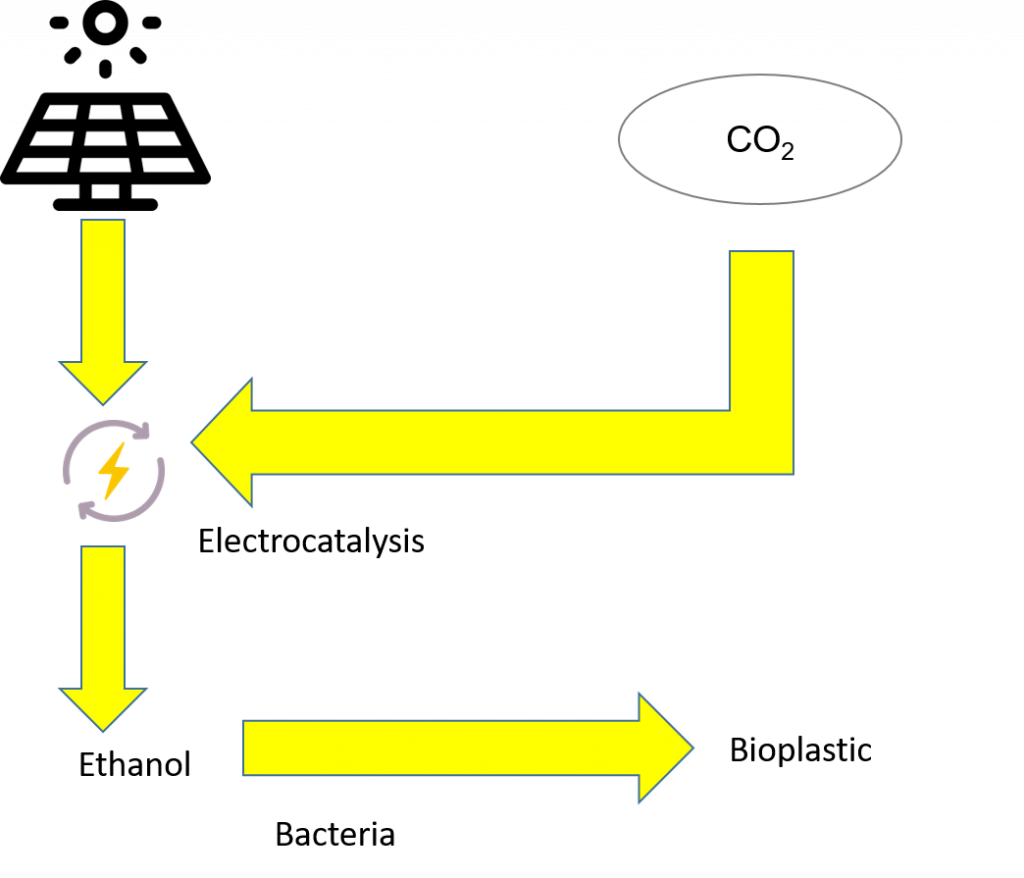

Texas A&M AgriLife researchers have developed a two-part system that uses carbon dioxide (CO2) to produce bioplastics. The first unit uses renewable electricity (solar) to convert carbon dioxide to ethanol and two other carbon molecules through a process called electrocatalysis. Additionally, in the second unit, bacteria consume the ethanol and carbon molecules to become a machine to produce bioplastics. This system has a much faster reaction rate than photosynthesis and higher energy efficiency.

Figure 1: Renewable Bioplastics by CO2 by Texas A&M AgriLife

CO2 to Bioplastics Conversion using Microalgae-

The University of Kentucky researched the technical and economic barriers to carbon dioxide (CO2) capture and utilization using microalgae. A combined photobioreactor (PBR) open raceway pond (ORP) cultivation system for bioplastics showed a higher algae productivity level than the traditional one. Additionally, this method is expected to improve the sustainability of the global plastics market by utilizing bioplastic feedstock (BPFS). This process develops BPFS rather than bioplastics.

Biohybrid System for Bioplastics with High Production Capacity

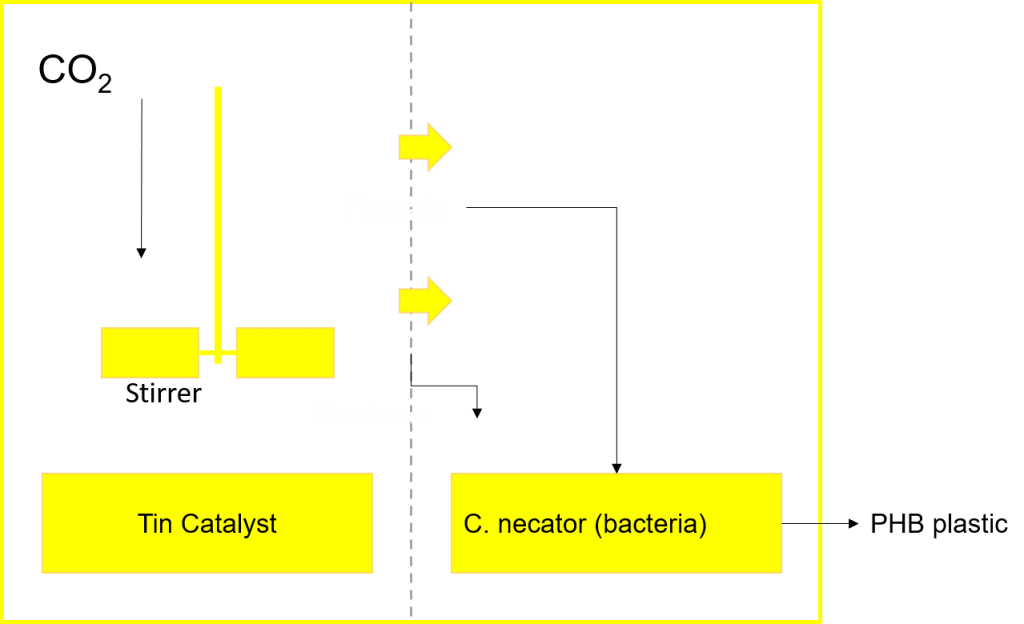

It is a highly scalable solution for bioplastic production that uses electricity, catalysts, and bacteria. The Korea Advanced Institute of Science and Technology developed it. The system includes a reactor with two chambers and a separating membrane. On one side, a tin catalyst-assisted chemical reaction converts carbon dioxide gas into a formate chemical. The formate then flows through the membrane to the other side, where C. necator (bacteria) ferments it to produce granules of the PHB plastic.

Figure 2: Biohybrid system for Bioplastics with high production capacity

Development of Foams and Plastics using Captured Carbon Dioxide

Ford was the first automaker to develop foams and plastics for its vehicle lineup using captured carbon dioxide in 2016. Formulated with up to 50 percent CO2-based polyols, the foam showed promise for seating and underhood applications. It was expected to potentially reduce Ford’s petroleum use by more than 600 million pounds annually.

Some other innovations include Aircarbon material by Newlight Technologies and Washington University’s research on TIE-1: Rhodomicrobium vannielii and Rhodomicrobium udaipurense bugs (microbes) for high CO2 to bioplastic conversion. The above innovations are still under development and do not disclose their application areas explicitly. However, with minor modifications in production and treatment processes, these bioplastics can easily be applied in the automobile industry.

Bioplastics in Automotive Industry: IP Activities

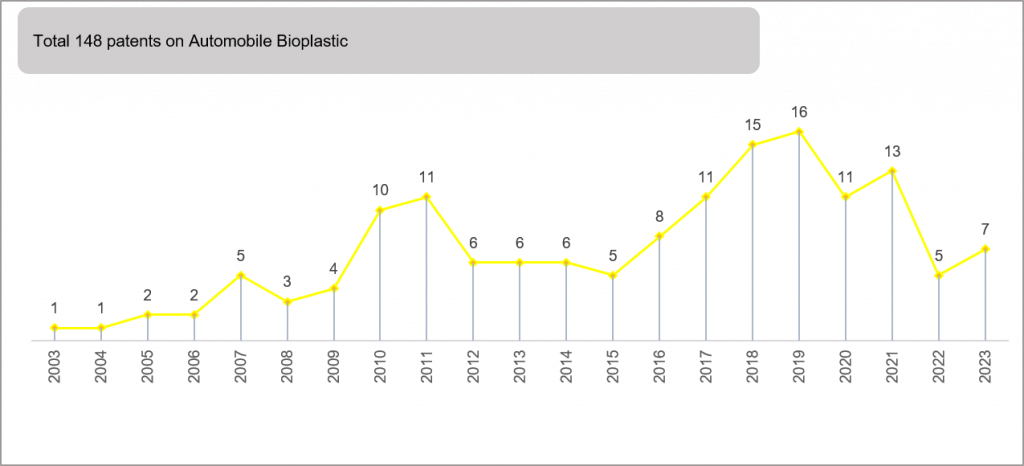

Carbon dioxide-based bioplastics for automobiles are a niche domain with very limited patents. Changchun Institute Of Applied Chemistry – Chinese Academy of Sciences, Shandong Lecsin Green Technology, King Abdullah University Of Science & Technology, and Shandong INOV New Material are the key assignees disclosing carbon dioxide-based bioplastics. Moreover, bioplastic process scalability for mass production and high conversion efficiency are the key challenges patents disclosing carbon dioxide-based bioplastics address. Since 2018, research on bioplastics for automotive applications has increased by 82%. The chart below represents the filing distribution of the patents disclosing the use of bioplastics in automobiles.

Figure 3: Priority filing trend of bioplastics in automobiles

Conclusion

CO2 bioplastics in the automotive industry is an emerging technology that addresses these challenges. Also, it is the ideal solution as it kills two birds with one stone by solving plastic pollution using CO2 from carbon capture and storage systems. It will also help reduce the indirect pollution caused by producing renewable biomass.

Once this technology successfully produces bioplastics economically, industries could replace traditional plastic products with fewer negative environmental impacts.