In the 21st century, prioritizing environmental sustainability is paramount, primarily in the food industry. Packaging plays an essential part in the food industry to preserve food safety. Due to its short lifespan, single-use culture, and mass production, food packaging contributes significantly to the environment’s rapid accumulation of plastic waste. It thereby also has a significant impact on environmental pollution.

Food packaging is something we use and throw away regularly because it doesn’t last long, so there is a continuous need for new packaging to replace it. This leads to a steady stream of plastic waste entering the waste stream. To address such issues and promote a sustainable approach to food packaging, there has been a surge in the development and introduction of biodegradable and bio-based polymers within the market.

Seaweed Packaging: Future of Sustainable Food Packaging

There has been a surge in the development and introduction of biodegradable and bio-based polymers into the market to address this issue and promote a more sustainable approach to food packaging.

Innovative solutions are continually sought as companies are always looking to reduce the environmental impact. One such solution gaining traction in the industry is seaweed packaging, a ground-breaking approach revolutionizing the concept of food sustainability.

Seaweed packaging originated from the depths of the ocean to gracing the shelves of supermarkets; it presents a compelling alternative to traditional plastic materials, representing the principles of a circular economy. Seaweed is widely used as a raw material in food packaging owing to its abundance, biodegradability, and low environmental impact. Overall, the abundant availability of seaweed, sustainable cultivation practices, and ongoing innovation in the industry position seaweed as a promising and accessible material for eco-friendly packaging solutions.

Seaweed Packaging – Nurturing Sustainable Growth?

Seaweed-based packaging, or seaweed bioplastics, are the packaging materials derived from various types of seaweed. These seaweed-based materials are eco-friendly alternatives to traditional plastic packaging and can be used in multiple applications. There are various approaches for sustainable packaging specifically for food applications, including edible packaging, biodegradable packaging, plant-based packaging, recycled paperboard & cardboard, mushroom packaging, reusable packaging, and others. Among them, one of the promising approaches is the utilization of edible film and coatings derived from seaweed, offering sustainable advantages for food packaging applications.

Edible films and coatings made from seaweed are thin layers of material that can be consumed with packaged food and removed before eating. They act as a protective barrier to increase the shelf life of perishable goods. These seaweed-based films are made from natural ingredients such as proteins, lipids, polysaccharides, and composite materials, which meet the industry’s growing demand for sustainable packaging solutions.

Seaweed – A Sustainable Source of Bioplastics?

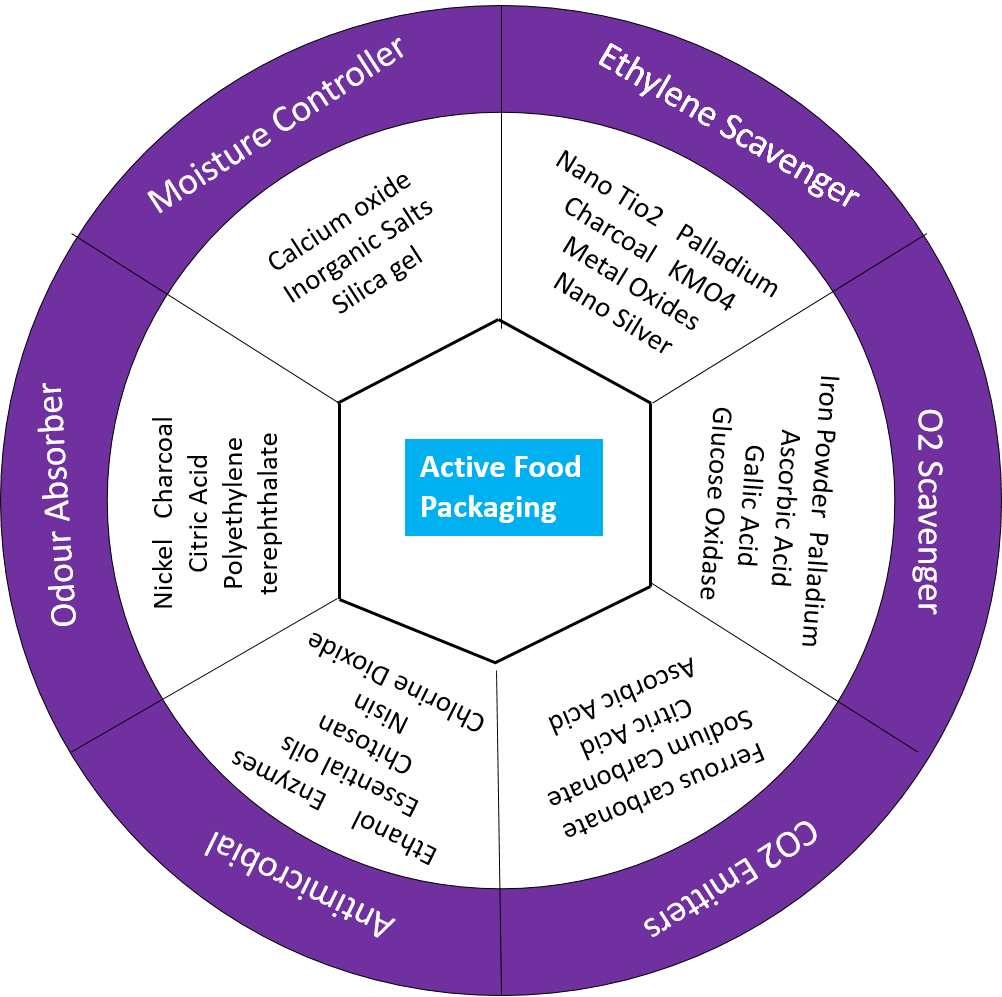

Seaweeds are rich in polysaccharides, making them promising materials for active packaging solutions in the food industry. Active packaging interacts with the internal environment of packaged products to increase its shelf life and quality. Active packaging involves the use of chemicals as an active agent in food packaging, which proves to be toxic due to the migration of chemicals from polymer to food. Consequently, researchers are more focused on utilizing natural compounds as active agents. Seaweeds are considered a better alternative to traditional food packaging material when combined with any biodegradable polymer. The use of seaweed enhances the product’s sustainability, functionality, and sensory properties.

According to the Food and Agriculture Organization (FAO) data, the global production of seaweed increased from 118,000 tons to 358,200 tons from 2000 to 2019. In 2019, Asia dominated seaweed production, with China alone holding around 56% of the global aquaculture.

Figure 1: Seaweed-derived sustainable packaging

Process of Seaweed Packaging

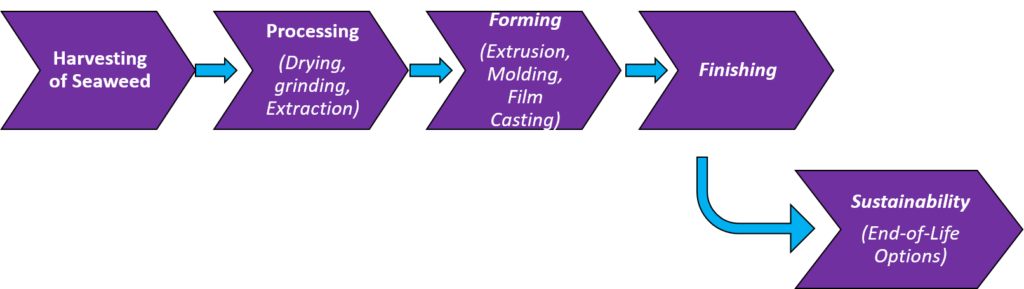

Seaweed is used to produce seaweed packaging through a process that involves harvesting, processing, and forming the seaweed into packaging materials.

Seaweed collected from coastal areas or seaweed farms is harvested and processed, which involves grinding, drying, or extracting components such as carrageenan or alginate. Further, the process of seaweed material is formed into packaging using various methods, including extrusion, molding, and film casting. These specific techniques produce various packaging formats, including trays, film, containers, and wraps. Once the packaging is formatted, it undergoes additional treatment, such as adding moisture or oxygen barriers to extend shelf life or improve the quality of the packaging.

Figure 2: Production Process of Seaweed packaging

Advantages of Seaweed Packaging over Tradition Packaging

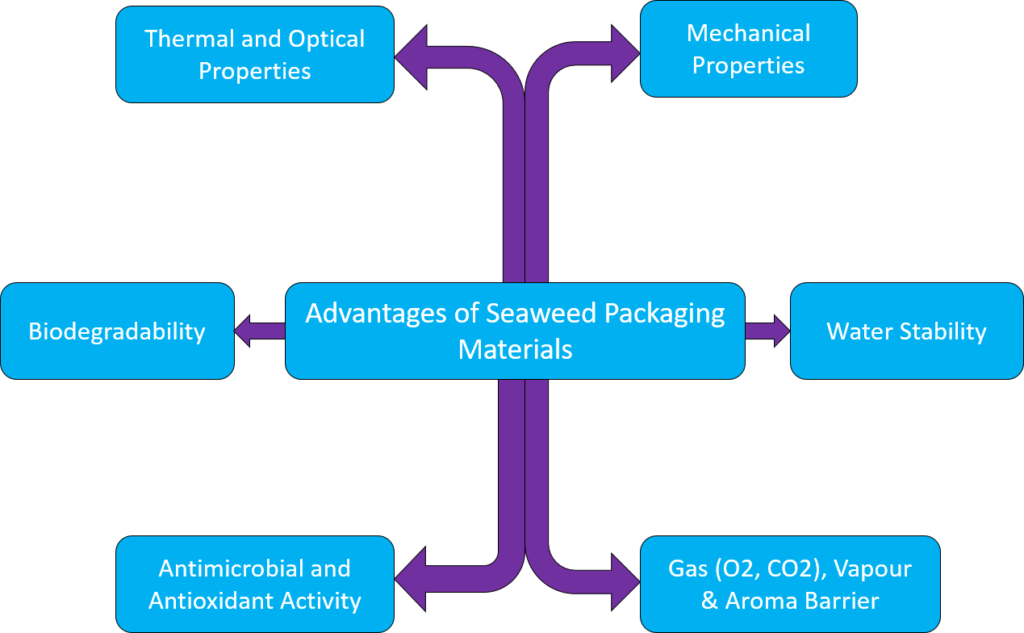

Seaweed packaging offers various advantages over traditional packaging materials. Some of the major advantages are as follows:

Biodegradability: Seaweed packaging is biodegradable and breaks down naturally into harmless substances, which reduces pollution and waste. It decomposes quickly, which helps to keep the environment clean and healthy.

Renewability: Seaweed is a renewable resource that can be sustainably cultivated without harming the environment. Seaweed is harvested and regrown in the marine environment, making it an environmentally friendly alternative for packaging food products, whereas petroleum-based plastics rely on non-renewable fossil fuels.

Barrier Properties: Seaweed-based packaging is an excellent barrier that helps maintain the freshness of food items. Moreover, for highly perishable seafood, it stops the entry of oxygen and helps preserve packaged seafood’s flavor, texture, and color.

These advantages offer functional and sustainable benefits for stakeholders and consumers, making them attractive options for the food industry.

Figure 3: Advantages of seaweed packaging materials

Application Diversity

Different composite materials are used in food applications to package seaweed. Each material is specifically used for food products based on its properties and advantages.

Different types of composites used in the food packaging applications:

Alginate/Nanocystalline Cellulose – Packaging Films for Food

Alginate/nanocellulose composite materials are increasingly used in polymeric packaging films for food due to several advantageous properties, such as compatibility with food contact, flexibility and strength, biodegradability, and enhanced barrier properties against moisture, oxygen, and other gases. This helps to maintain the freshness and quality of packaged food for a longer period of time.

Alginate/Starch – Packaging of pre-cooked ground beef patties

The alginate/starch packaging is used in pre-cooked ground beef patties, helping retain moisture and keeping patties juicy and flavorful. It acts as a barrier to prevent patties from becoming soggy or losing their shape, preserving texture. Additionally, it increases patties’ shelf life by inhibiting microbial growth and oxidation, reducing food waste, and improving quality.

Alginate/Cinnamon Essential Oil – Edible Film for Food, Quality Retention of Fresh-cut Pineapples

Pineapples have a relatively short shelf life compared to some other fruits due to their high moisture content and susceptibility to microbial spoilage. The antimicrobial properties of cinnamon essential oil can help prevent the growth of spoilage microorganisms, thereby maintaining the freshness and quality of the fruit for a longer period.

Carrageenan/Glycerol – Packaging of Instant Noodles, Flavoring, Coffee Mix, Candy Wrappers, and Others

Carrageenan, a natural polysaccharide derived from seaweed, has excellent film-forming properties, allowing it to create thin, flexible, and transparent films. These films can be used as packaging materials for instant noodles, flavoring packets, coffee mix sachets, and candy wrappers, providing a protective barrier while allowing consumers to see the contents inside. Other benefits of packaging are that it is a natural and biodegradable material, it also offers barrier properties, and it retains moisture.

K Carrageenan – Sachet, Interleaf for Frozen Foods

K Carrageenan is extracted from red seaweed and has high gel strength and stability, which is suitable for frozen food packaging. It also offers advantages such as barrier properties, thermal stability, moisture retention, and safety, ensuring the quality and freshness of frozen foods.

Carrageenan/Locust Bean Gum/Nano Clay – Shelf Life Extinction of Food

The combination of carrageenan, locust bean gum, and nano clay enhances barrier properties, structural integrity, and moisture retention in food packaging. Nano clay also enhances packaging strength and durability, making it more resistant to damage during handling, transportation, and storage.

Trends of the Seaweed Packaging in Food Applications

Expansion of Packaging Product Range-

The manufacturers of seaweed packaging are exploring new packaging formats, branching out traditional films to include trays, containers, and even edible packaging options. The diversification caters to varying consumer preferences and expands the potential applications of seaweed packaging across the food industry.

Read Here: How Seaweed Packaging is Helping in Sustainable Waste to Energy Technology

Integration of Functional Properties into Seaweed Packaging Materials:

By mixing essential oils, antioxidants, and antimicrobial agents into seaweed-based materials, packaging enhanced food shelf life, ensuring food safety and quality assurance.

Figure 4: Startup Companies in the Seaweed-based Packaging Industry

Startup Companies that create Plastic from Seaweed

Kelpi

- Kelpi is an innovative biotech firm headquartered in the UK that offers sustainable bioplastic packaging solutions. It was founded in 2020 by Neil Morris, Murray Kenneth, and Chris Chuck.

- The company has successfully raised more than $3 Mn in funding to develop its technology, which creates biomaterial coatings from seaweed. Over the past 2.5 years, the company developed high-performance materials from seaweed, including exceptional water barrier properties, oxygen barrier capabilities, and resistance to grease and acid. Additionally, the seed funding for the company was led by the Science Creates Ventures and Green Angel Syndicate, with funding from One Planet Capital and other private angel investors.

Notpla

- Notpla is a Londan-based packaging company specializing in developing innovative packaging solutions derived from seaweed to replace single-use plastic. In 2021, the company secured $13.3 Mn Series A funding from investors to introduce its flagship product, “Oooh.” This funding has significantly accelerated the company’s aspiration to reduce single-use plastic.

- The Ooho product has successfully replaced 500,000 single-use plastic at prominent events such as the London Marathon. The investor Horizons Ventures and other existing investors such as Astanor Ventures, Lupa Systems, and Torch Capital led this funding.

Zerocircle

- Zerocircle is an India-based company that manufactures industrial packaging materials using seaweed. The seaweed is sourced from Maharashtra, Tamil Nadu, and Gujrat coastal areas. Raised $2.99 Mn in pre-seed rounds from Rainmatter Foundation, Sequoia Spark, and other undisclosed investors to strengthen its R&D and regenerative company profile.

Sway

- Sway is a US-based company that offers seaweed-based packaging. The company uses seaweed plastic for shopping bags and wrapping clothes.

- In 2023, the company raised $5 million in seed funding to scale up its product portfolio, including thermoplastic seaweed resin. Bio-based pellets are excellent replacements for single-use plastics like food wrappers, polys, and retail bags. The company employs seaweed farmers in Maine, United States, for its kelp production.

The other players included in the seaweed packaging are Evoware, Algopack, Loliware Inc., DisSolves, Searo, B’ZEOS, and others.

Adoption of Seaweed Packaging by FMCG Giants

FMCG companies are looking into seaweed packaging as a green alternative to traditional packaging materials. Unilever, an FMCG player, is focusing on eco-friendly packaging. They have also announced trials for seaweed-based packaging in 2019 for its brand, Hellmann’s mayonnaise. After the trial, the company partnered with Just Eat and Notpla to serve Hellmann’s ketchup, BBQ, tartare, and garlic sauces in seaweed sachets.

Another FMCG giant, Nestle, has committed to achieve 100% recyclability or reusability of all its packaging by 2025. Recently, B’ZEOS collaborated with Nestlé to develop food packaging prototypes. Through this collaboration, B’ZEOS and Nestlé are likely to combine their knowledge in materials science, packaging design, and food safety to create prototypes that meet the rigorous requirements of the food packaging industry while aligning with sustainability goals. B’zeos is working on the pilot scale of prototypes to meet the desired specifications, which will then be made to scale up production to commercial levels.

Lucozade is a British brand of soft and energy drinks manufactured and marketed by the Japanese company Suntory. In 2022, it piloted the edible seaweed packaging filled with its sports drinks and gels at the Richmond Marathon and Tough Mudder sporting events. The brand collaborated with Notpla for its pilot-scale project.

Just Eat, a prominent food delivery platform, has partnered with global brands PepsiCo and Heineken, as well as Notpla, a packaging startup in 2023. Just Eat is working with UEFA on an initiative alongside PepsiCo and Heineken. This initiative aligns with the company’s broader strategy, seeking innovative solutions to eliminate single-use plastic. The company has forged a partnership with Notpla to supply 85,000 seaweed-lined packaging across three UEFA football matches.

The adoption of seaweed packaging by FMCG companies is still in its early stages, but there is growing interest and momentum within the industry in exploring sustainable packaging alternatives. With the increase in demand for environmentally friendly products, the giant FMCG players are progressively investing in R&D and partnerships to develop seaweed-based packaging for their product offerings.

Conclusion

The packaging industry and key players in the sector worldwide are focusing on sustainability, and seaweed-based packaging is emerging as a viable solution due to its sustainability, recyclability, and abundance of seaweed. FMCG giant players such as Unilever, Nestle, and PepsiCo use seaweed packaging for food applications because of its superior properties and benefits.

The seaweed packaging market is likely to increase owing to growing consumer awareness, technological innovations, the collaboration of stakeholders, and regulatory support for sustainable food packaging. However, scalability, cost, and regulations limit the industry’s growth. Balancing these drivers and restraints is essential for businesses to effectively integrate seaweed packaging into their operations.