Hyperautomation can be considered the future of industrial automation and processing. Various companies are currently making efforts to introduce hyperautomation in industries and businesses. Hyperautomation in industrial manufacturing is the key technology that drives innovation and simplifies business processes. Implementing hyperautomation in industries includes utilizing multiple technologies, including RPA, machine learning, and AI, to reduce workflow and boost productivity. These multiple technologies, tools, or platforms are simply known as hyperautomation tools.

The article answers the following questions: what is hyper-automation, what are its benefits, how will it change the paradigm of working in industries, and how can it be implemented to integrate with the industries and business purposes?

What is Hyperautomation, and What Are Its Benefits?

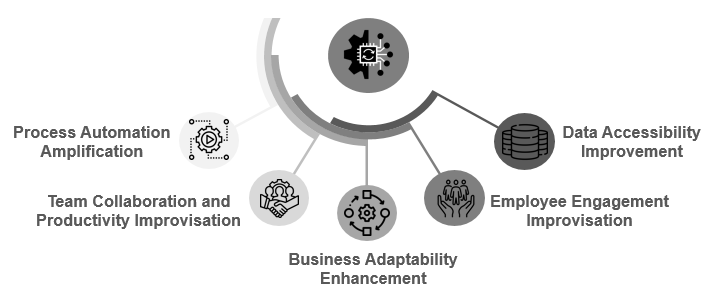

Hyperautomation is business process automation that integrates combined tools into a workspace. In other words, it integrates the automation process with tools and technologies to amplify the ability of process automation in industries and businesses. There are various benefits to integrating hyperautomation in industrial processes. Some of the hyperautomation tools are listed below:

- Process Automation Amplification: Introducing robotic process automation (RPA) relieves companies from monotonous tasks and makes the work of the staff easy. Hyperautomation tools will increase productivity by combining a group of technologies and tools with industrial processes.

- Team Collaboration and Productivity Improvisation: Hyperautomation will provide a smooth connection between the staff and companies. Users can collaborate with other users using RPA, hyperautomation software, and other intelligent hyperautomation tools, which will help in easy interaction and increasing production.

- Business Adaptability Enhancement: Business adaptability refers to the capability to adapt according to the demands of the conditions. Hyperautomation will allow organizations to easily adapt and scale their processes according to the changing needs and demands of the consumer. Businesses can maintain pace and adapt to the changing market dynamics using smart hyperautomation tools.

- Employee Engagement Improvisation: Hyperautomation can improve work quality with the use of modern technology that makes manual labor more manageable. It will increase employee satisfaction and workforce engagement.

- Data Accessibility Improvement: Companies can expect more seamless interactions between consumers and their infrastructure as hyperautomation aims to merge current technologies and procedures for greater efficiency. Because all enterprise systems can interact seamlessly, a centralized storage facility can access all fundamental aspects.

Hyperautomation In Industrial Manufacturing: Transforming Operations

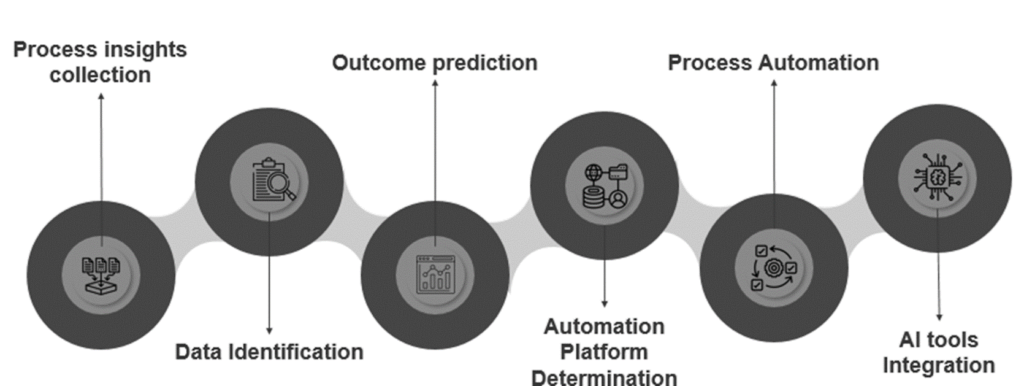

The following processes are used to automate industrial workflows and help implement hyperautomation in industries and businesses.

- Process insights collection: To integrate hyperautomation with industrial processes, organizations can use process mining as a stepping stone and understand the workings of existing processes. Also, identify lags and bottlenecks and pinpoint areas that can be improved through hyperautomation

- Data Identification: After identifying information related to the existing process, the system collects structured and unstructured data and other inputs related to automating the existing processes.

- Outcome prediction: After gathering the information gathered, we will predict the output for return on investment (ROI) and process efficiencies

- Automation Platform Determination: After predicting outputs for the processes, the system determines a suitable automation platform for the process

- Process Automation: The process of automation is carried out on a suitable determined platform

- AI tools Integration: During automation, companies integrate various AI tools to enable hyperautomation in industrial manufacturing and business processes

Hyperautomation In Industrial Manufacturing: Implementation

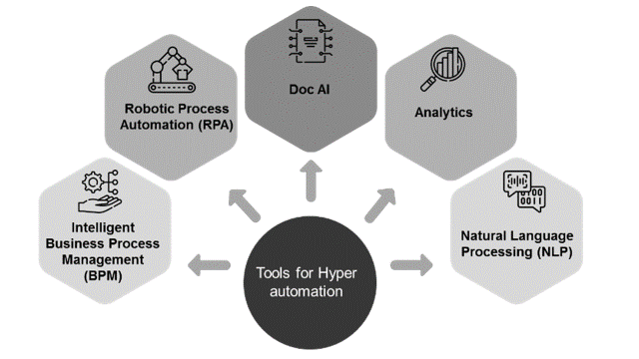

The following are the tools that aid in the successful implementation of hyperautomation in business processing and industrial automation:

- Intelligent BPM: Traditional BPM platforms optimized business process workflows to improve outcomes and efficiency. Low-code Intelligent Business Process Management (iBPM) integrates the traditional BPM tool with AI, cloud capability, analytics, and complex events processing, thus transforming business operations and becoming the support pillar for hyperautomation implementation.

- RPA: Robotic Process Automation (RPA) bots are faster than humans. This saves humans time to perform complex tasks that require better focus and creativity. RPA can expedite processes such as invoice processing, account settlement, web scraping, or auto-updating CRM records. By reducing cycle times and throughput upgradation, RPA increases accuracy, flexibility, and scalability.

- Doc AI: To derive a large amount of data and valuable information from unstructured data, Doc AI can be a big help. AI is a sequence of intelligent processes that help identify technologies like intelligent optical character recognition (OCR), natural language processing (NLP), and machine learning (ML). Doc AI uses artificial intelligence that uses technologies like intelligent optical character recognition (OCR), machine learning (ML), and natural learning processes to implement hyperautomation in data processing. Doc AI has various applications in processing form, contract management, conversational FAQ, etc.

- Analytics: Analytics translate data to information across industries. They help translate industrial data into useful information, predict outcomes based on past data, and provide suggestions for increasing return on investment (ROI). Analytics platforms consist of in-built dashboards that provide valuable insights to the user and help the user make decisions related to supply chain, finance, risk, etc.

- Natural Language Processing (NLP): Natural language processing (NLP) analyzes semi-structured, unstructured, and structured data for data identification, extraction, and analysis. Various applications utilize NLP for tasks such as handling insurance claims, processing invoices, classifying text, detecting spam or fraud, and more. Combining NLP with RPA will help better analyze sentiments in the text and thus improve customer experience.

Use Case Scenarios

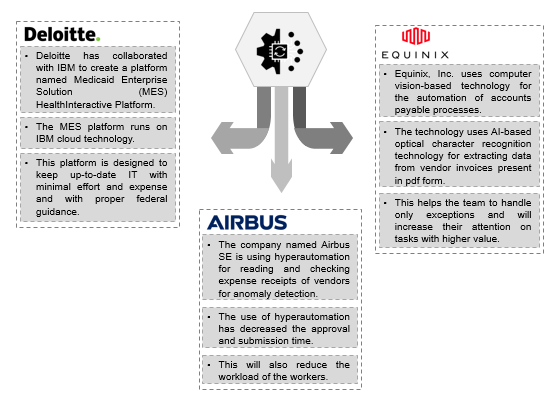

Various projects are undergoing the implementation process of hyperautomation. The table below presents some of them:

Figure 4: Hyperautomation Use case Scenarios in data processing.

Conclusion

Hyperautomation can be the future of industrial processes and manufacturing. Many big players, such as Deloitte, Airbus SE, Equinix, etc., are working in this direction. Also, designers have created various tools to increase the chances of successfully implementing hyperautomation. The progressive development in this field can simplify the execution of monotonous and time-consuming tasks, thus allowing employees and workers to use their creative instincts in tasks needing more attention and expertise.