Acrylamide (C3H5NO) is a white, odorless, and crystalline compound synthesized by-product of a Maillard reaction between a carbonyl compound (preferably an alpha-hydroxy carbonyl) and asparagine, an amine compound. It is also known as Acrylic acid amide, Ethylenecarboxamide, 2- Propenamide, Propenoic acid amide, or Vinyl amide and was practically manufactured for use in commercial purposes by the reaction between acrylonitrile and hydrated sulfuric acid. It is generally used for synthesizing various polymers and copolymers, which are meant for various functional uses. For polyacrylamide production, the synthesis of dyes and copolymers meant for incorporation in contact lenses, and the construction of tunnels, its monomeric form can be used as a chemical intermediate. Besides the above functionalities, the acrylamide polymers are also utilized as additives for soil conditioning agents, water treatment, sewage and waste treatment, paper-making aids, etc. The acrylamide gel is known to be used in laboratories for electrophoresis and is normally employed in genetic engineering/molecular biology.

The single unit of acrylamide is known to be a suspected carcinogen in humans, whereas its polymeric form has no toxic effects. Food products rich in carbohydrates processed at temperatures above 120°C, such as potato chips or French fries, tend to contain high levels of acrylamide. Since these types of processed foods are widely consumed, the concern of acrylamide has become even more crucial. Hence, it should be properly regulated and monitored. Certain acrylamide reduction in food strategies must be implemented to adequately prevent a widespread lifestyle hazard. The inhalation of tobacco smoke can also act as a potential exposure to acrylamide. Its amount has been estimated to be 1.1–2.34 mg per cigarette.

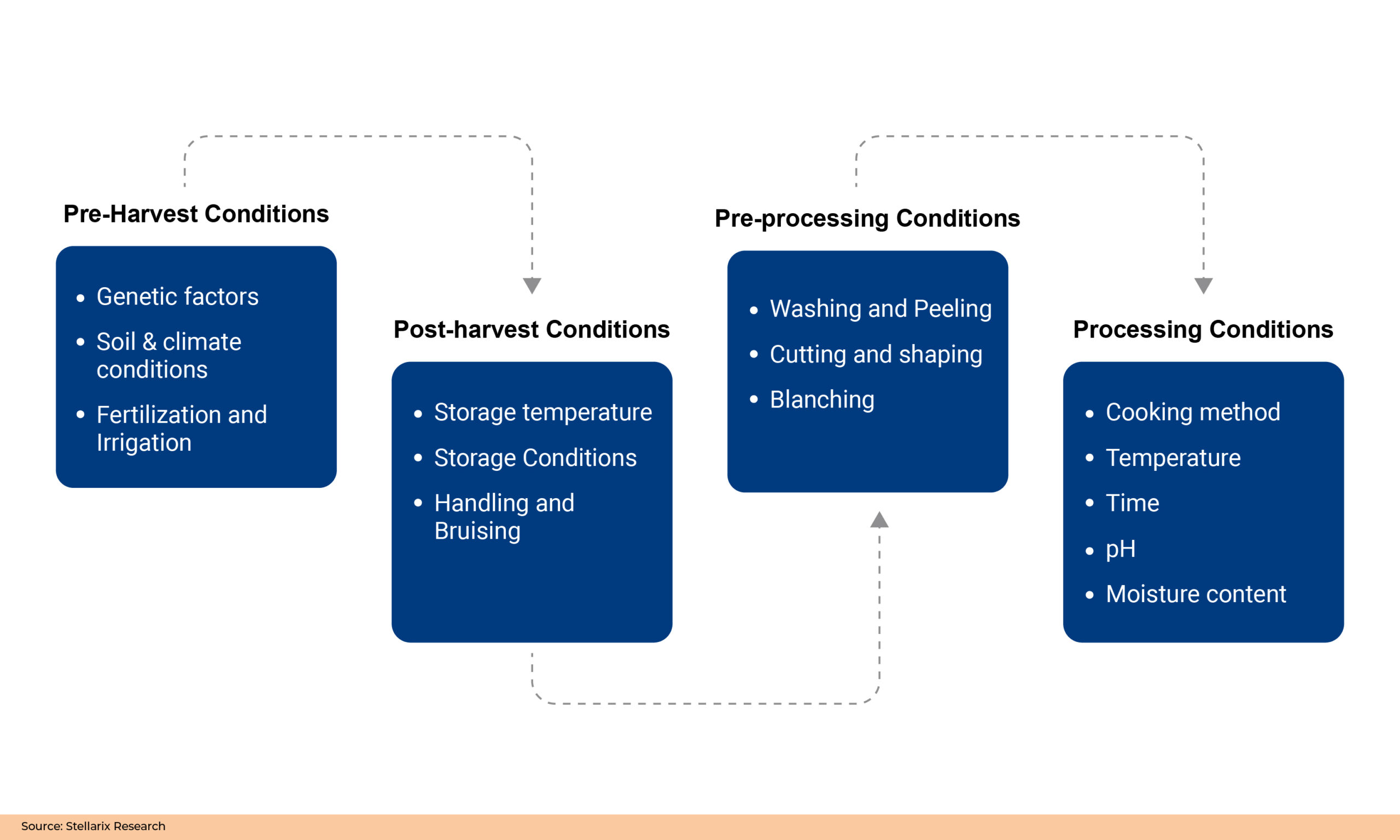

Factors Influencing Acrylamide Formation

Food Products Prone to Formation of Acrylamide

Regulatory Aspects

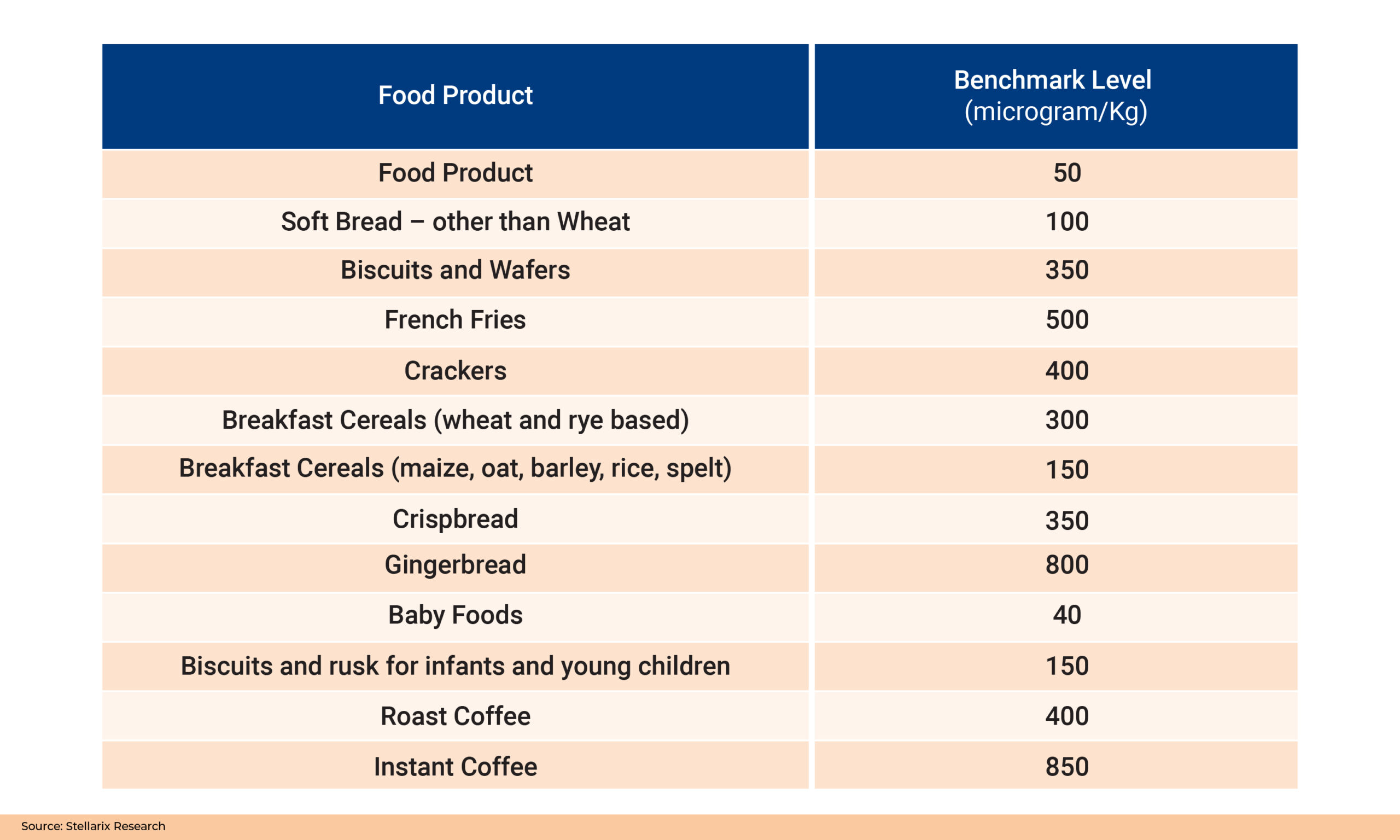

- The European Food Safety Authority confirms that acrylamide is a carcinogenic substance and that the current level of acrylamide concentration in food products poses a threat to life. The EU Regulation from 2018 (EU Regulation 2017/2158) intends to set limits on acrylamide levels in food products and guide food business operators to mitigate or minimize the acrylamide content in food products.

- For different food products, the benchmark level of acrylamide is presented below:

Detection Methods of Acrylamide in Food

Different methods for detecting acrylamide are available, ranging from conventional instrumental methods to rapid immunoassay and supramolecular recognition. Methods such as capillary electrophoresis and immunoassay are sensitive and faster methods of detecting acrylamide in food. Above all, biosensors are emerging tools for identifying acrylamide in food. This category includes electrochemical sensors and fluorescent sensors with real-time monitoring. They help in providing food safety and security.

Gold Standard Diagnostics offers an ELISA-based ABRAXIS® Acrylamide-ES kit for detecting acrylamide in potato/corn chips, French fries, cereals, and bread. Waters6 provides an analysis starter and refill kits to detect acrylamide in food through LC-MS/MS. The kits are easy to use.

Acrylamide Reduction Solutions

Acrylamide formation in food products can be reduced with the application of following different strategies.

- Plant Cultivation Approach: Higher nitrogen and lower sulfur concentrations result in an increase in asparagine concentration in cereals. Optimized concentration of nitrogen and sulfur reduces asparagine and sugar content further reducing acrylamide production.

- Food Processing Approach: Processing parameters, such as storage conditions, frying temperature

and time, use of additives, soaking, extended fermentation time, and optimization of baking conditions are effective tools for controlling acrylamide formation in food products.- Enzymatic Mitigation: c-LEcta and ANKA developed an innovative food enzyme called Acrylerase® to reduce acrylamide levels in instant coffee and ready-to-drink beverages. These patented enzymes directly target the acrylamide and have benefits over the existing preventive measures.

- Temperature and Time Conditions: The study has reported increased acrylamide formation in potato chips during high temperatures and increased frying time. Chips fried at high temperature with short frying time (160°C for 7 minutes) reported reduced acrylamide production.

- In another study, lowering baking temperatures from 200°C to 180°C lowers the acrylamide content in biscuits.

- Use of Microorganisms and Extended Fermentation Technology:

- The use of specific microorganisms like Pediococcus pentosaceus for the preparation of sourdough, which is further used in bread, results in lower-level acrylamide formation.

- In another study, the use of lemon juice, rosemary juice, and spent coffee with extended fermentation helps in the reduction of acrylamide formation during whole wheat bread preparation.

- Edible Films and Coatings: Edible coating prepared using whey protein and natural antioxidants from rosemary reduces the formation of acrylamide in the potato chips without affecting the taste and texture

- Plant Extracts: In a research study, the scientist tested the effects of ginger, fennel, and borage extracts on the formation of acrylamide in fried potato and showed that all extracts had the potential to reduce acrylamide contents.

- Red Tara Pods (Caesalpinia spinosa) Extract can be used to reduce the acrylamide formation in crackers by reducing the Maillard reaction without affecting the sensory properties.

Ongoing Projects

CA21149 – Reducing acrylamide exposure of consumers by a cereals supply-chain approach targeting asparagine (ACRYRED) – Reduce acrylamide formation in cereal-based products through better breeds and farming practices, down-streaming acrylamide formation in cereals, measure the content of free asparagine content in the raw materials. This project is in collaboration with the Slovak institution National Agricultural and Food Centre, the Serbian Institution University of Novi Sad, and the Institute of Food Technology.

Future Aspect of Reduction of Acrylamide in Food

The rise in consumer interest in healthier foods continues to grow, and the food industry faces mounting pressure to curtail acrylamide levels in growing products. Some of the key aspects that need to be considered for acrylamide reduction include:

- Developing innovative processing technologies to reduce acrylamide formation, such as advanced thermal processes that provide better control over acrylamide formation in the processing of foods

- Natural and cost-effective additives and ingredients that reduce acrylamide formation during processing need to be screened. Acidifying ingredients, including citric acid, vinegar, etc., and ingredients such as red tara pod that reduce Maillard reaction will play a significant role

- Advanced analytical techniques for detecting and measuring acrylamide in different foods need to be developed to monitor and control acrylamide levels in food

- Cost-effective and sustainable technologies/ methods can be adopted to reduce acrylamide formation without increasing the production cost of the food product