HVAC is one of the potential sectors contributing to global warming, as they emit CFCs which are up to a thousand times more potent to global warming than CO2. The researchers from Texas A&M University come across “a 3D printable phase-changing composites which can regulate temperatures inside buildings” as a solution to HVAC-led global warming. The phase change material (PCM) industry has a bright future, with prospects in the building and construction, HVAC, cold chain & packaging, TES, refrigeration & equipment, electronics, and textile industries. Increased awareness of the need of reducing greenhouse gas emissions and rising demand for renewable energy sources are the key growth factors for this industry.

3D Printable Phase: Background & Overview

Global warming has been a conundrum for humans since its inception. The situation is undoubtedly the result of human acquisitiveness. The whole thing gained momentum with the Industrial Revolution. However, the era witnessed a drastic breakthrough in technological innovations, which gave birth to various new technologies such as steam engines, sewing machines, printing presses, etc. As they say, nothing comes for free. With heavy industry coming in, CO2 emissions began. Carbon emissions recorded during the mid-1700s were around 280 ppm, which has been continuously rising since then. Thus, 3D technology is taking over in different forms.

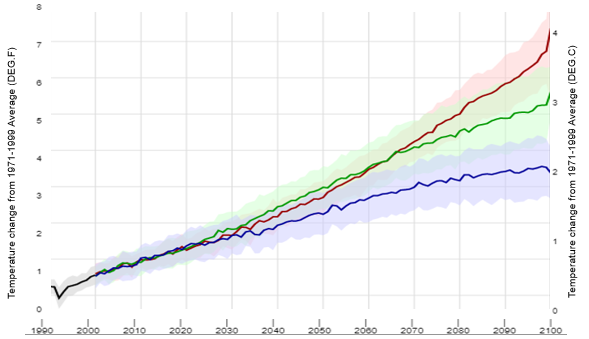

As a result, the recorded rise in temperature till 2020 is 0. 7 degrees Celsius, and it is anticipated to rise by 1.2 degrees Celsius by 2050. The phenomenon seems more alarming as the recorded CO2 PPM level in 2019 was 409.8 ± 0.1, whereas in 2020, it was 417.16.

Despite the fact that the year 2020 was subject to a lockdown period for a significant period of time due to a pandemic, emissions of CO2 still recorded a rise. Therefore, it is time to address the issue before it is too late.

Figure 1: A detailed prediction of temperature rise

Problem

Heating, Ventilation, and Air Conditioning (HVAC) systems are the most popular temperature regulation methods in homes and commercial establishments. These technologies, however, use a huge amount of energy. They also use greenhouse gases, known as refrigerants, to generate cool and dry air. These lingering issues with HVAC systems have led to research into alternative materials and technologies that require less energy to function and can control the temperature commensurate with HVAC systems. According to the calculations by the World Economic Forum, greenhouse gas emissions from air conditioning may account for a 0.5-degree Celsius rise in global temperatures by the end of the century.

Solutions

To contribute to the environment, the HVAC business focuses on sustainable technologies. Geothermal heating and cooling systems exchange heat with the ground and are examples of sustainable HVAC technology.

Recently, researchers from Texas A&M University came across a novel 3D-printable phase-changing composite that can regulate temperatures inside buildings. When heated, a hollow house, printed with PCM-filled ink, maintained a 40% lower temperature than the external environment.

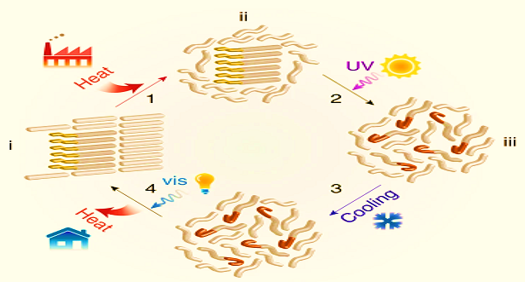

PCMs have been explored as an HVAC alternative, which uses the latent heat from surroundings (when the temperature rises above a threshold) to undergo a phase change, thus producing the cooling effect.

Figure 2: Working Principle

A reverse cycle occurs (when the temperature falls below a threshold) to undergo a phase change to release the heat absorbed during the cooling cycle.

Researchers have been focusing on integrating PCMs into the construction sector for a long time. This includes integrating the PCMs with different nanomaterials in cement binders. However, the efforts faced many challenges, such as reducing the actual amount of PCMs, reducing efficiency, PCM leakage, etc.

The researchers approached the problem by combining the light-sensitive liquid resins with a phase-changing paraffin wax powder to create a new 3D-printable ink composite. One can add this composite to building materials, like paint, or 3D print it as decorative accents. It is even stated that the composite is UV-resistant.

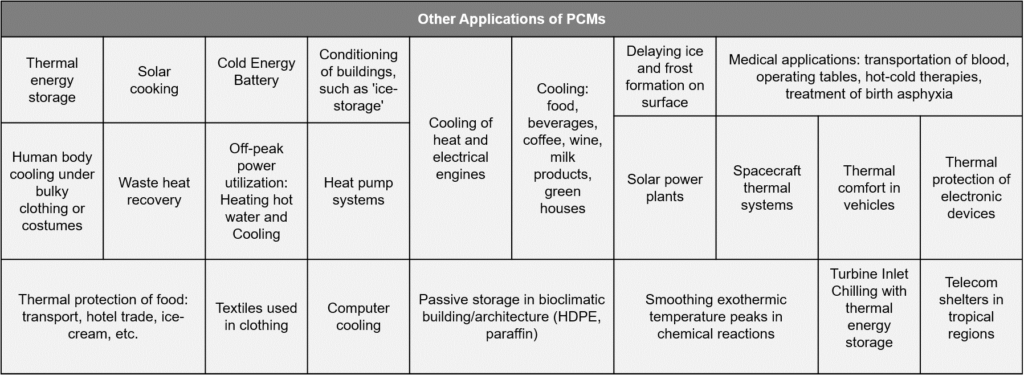

Other Applications of PCMs

Market Statistics in 3D Printable Phase

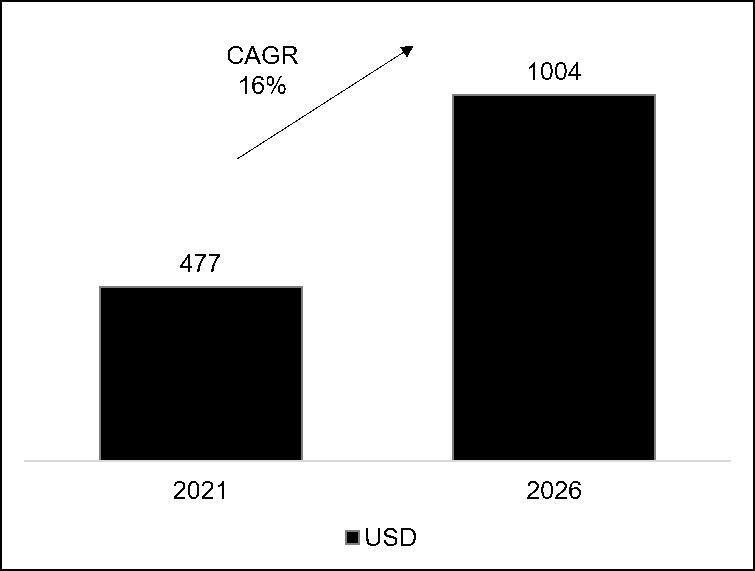

The Phase Change Material (PCM) market is expected to grow at a 16.0 percent CAGR from USD 477 million in 2021 to USD 1004 million by 2026. Regulations to minimize greenhouse gas emissions, as well as the usage of PCM for temperature control and enhanced comfort, are driving market expansion. Another factor propelling its growth is the use of phase change material for peak-load shifting.

Key Players in Phase Change Materials

The below-mentioned players are among the top players in the phase-change material market. Besides these, a few known players in the domain are Phase Change Solutions, Rubitherm Technologies, Phase Change Materials Product Ltd, Outlast Technologies, Henkel Electronic Materials, and PureTemp LLC.

- Phase Change Solutions: Phase Change Solutions is a global leader in temperature control and energy-efficient solutions and uses phase change materials that stabilize temperature across a wide range of applications. The company has patented a segment of products, namely BioPCM® products. BioPCM® absorbs and releases heat; the material can transition phases between solid-to-gel and solid-to-solid, which is a key differentiator from existing PCMs that transition phases between solid to liquid.

- Rubitherm Technologies: Rubitherm Technologies GmbH is an expert in PCM technology. Rubitherm delivers inorganic and organic PCMs in large and small quantities and refines PCM with micro and macro-encapsulation. The company is about to launch water-based PCM storage, which will eliminate the need to reduce the switching cycles for refrigeration.

- Phase Change Materials Products Ltd: Phase Change Materials Products provides PCM solutions covering a range of applications between -100°C (-148°F) and +885°C (+1,625°F). There are four main categories in PCM Products’ range: eutectics, salt hydrates, organic materials, and temperature salts.

- Outlast Technologies: The company started its journey by developing thermo-technology for NASA. Outlast Technologies incorporates Thermocules, microencapsulated phase change materials, into fabrics and fibers for absorbing, storing, and releasing excessive heat.

- Henkel Electronic Materials: Henkel operates worldwide with leading innovations, brands and technologies in three business areas: Laundry & Home Care, Beauty Care and Adhesive.

- PureTemp LLC: PureTemp LLC is a bio-based specialty chemical company. PureTemp phase change materials are developed to capture and emit a huge amount of thermal energy at certain temperatures. The products are derived from 100% sustainable sources, such as animal fat and plant oil. PureTemp’s PCM is nontoxic and biodegradable.

Potential Applications of 3D-printed phase-changing Composites

- Temperature-Regulating Building Solutions: Employing 3D-printed phase-changing composites in building materials, such as paint or decorative accents, offers a novel approach to regulating temperatures within structures, enhancing overall energy efficiency.

- Smart Textiles Advancements: Integrating phase-changing materials into textiles, including clothing, opens avenues for regulating body temperature, providing insulation, and significantly enhancing overall comfort.

- Innovative Consumer Products: The versatility of 3D-printed phase-changing composites extends to creating consumer goods like mugs, cups, and smartphones. These products can dynamically change temperature in response to user input or environmental conditions.

- Industrial Process Enhancements: In various industrial processes, such as heat management systems, cooling lubricants, and thermal energy storage devices, applying phase-changing materials proves valuable, contributing to improved efficiency.

- Advanced Energy Storage Solutions: Leveraging 3D-printed phase-changing composites in energy storage allows for developing cutting-edge solutions capable of storing and releasing energy in response to shifting temperatures and environmental conditions.

- Integration in Aerospace and Automotive Components: The utilization of phase-changing materials in aircraft, spacecraft, or automotive components presents opportunities to manage temperature effectively, thereby enhancing overall performance in these critical industries

Future Prospects

The phase change material (PCM) industry has a bright future with prospects in the building and construction, HVAC, cold chain & packaging, TES, refrigeration & equipment, electronics, and textile industries.

Increased awareness for the necessity of reducing greenhouse gas emissions and increased adoption for renewable energy sources are the key growth factors for this industry. The widespread use of PCM at various stages of the building construction process holds significant potential for achieving net-zero-ready buildings. Consequently, it can make a substantial contribution to the realization of carbon-free construction.