Traditional heavy vehicles are key contributors to the disproportionate amount of air emissions, and the directive on clean energy enables advancement in technologies focusing on renewable fuels and battery technology to improve infrastructure, reliability, and efficiency in zero-emission heavy vehicles.

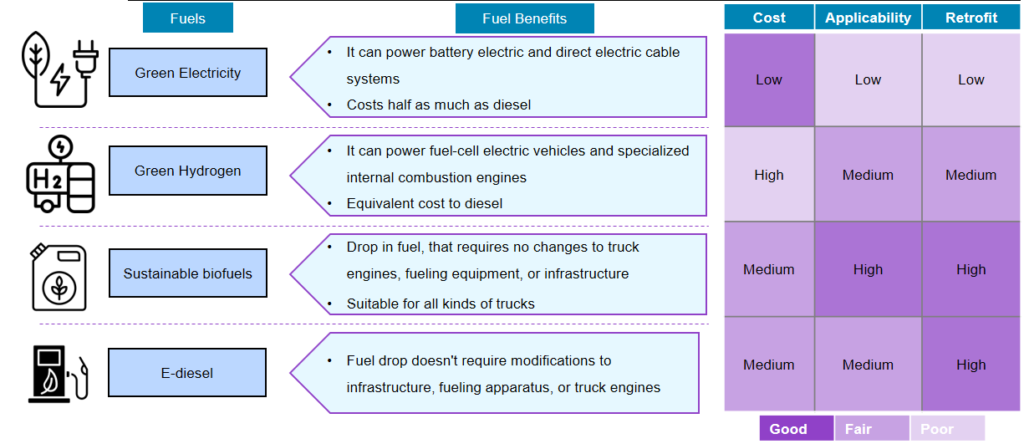

Sustainability in heavy vehicles involves improving fuel efficiency and environmental impacts using alternative fuels such as green (electricity, hydrogen), biofuels, and E-diesel, lightweight and high-strength materials, and implementing efficient powertrain technologies that proportionally empower electric propulsion systems’ reliability.

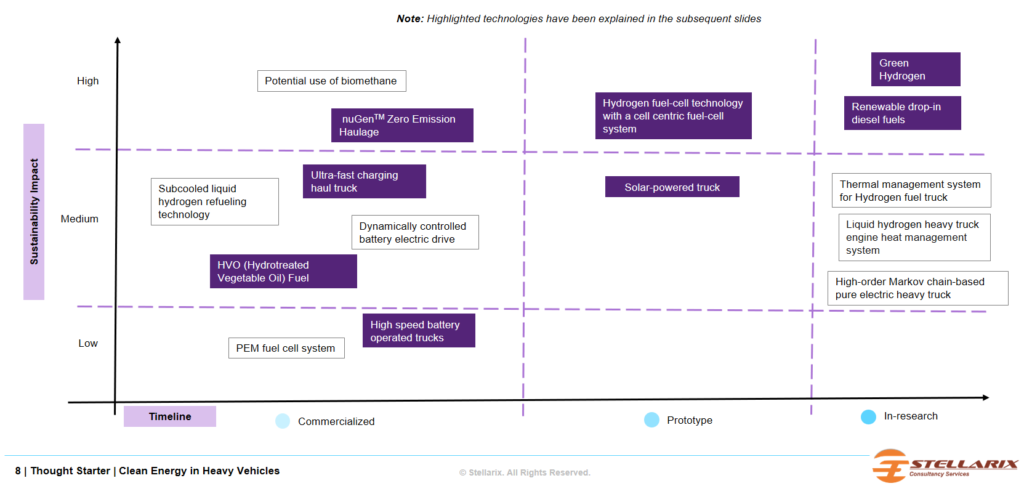

To make clean energy more viable, heavy vehicle companies are focusing on improving charging speeds and finding cell chemistries with better energy density. For this, they are investing in infrastructure and hydrogen fuel cell technology. Further, hybrid systems (a combination of clean energy with conventional sources) are being developed to provide more flexibility.

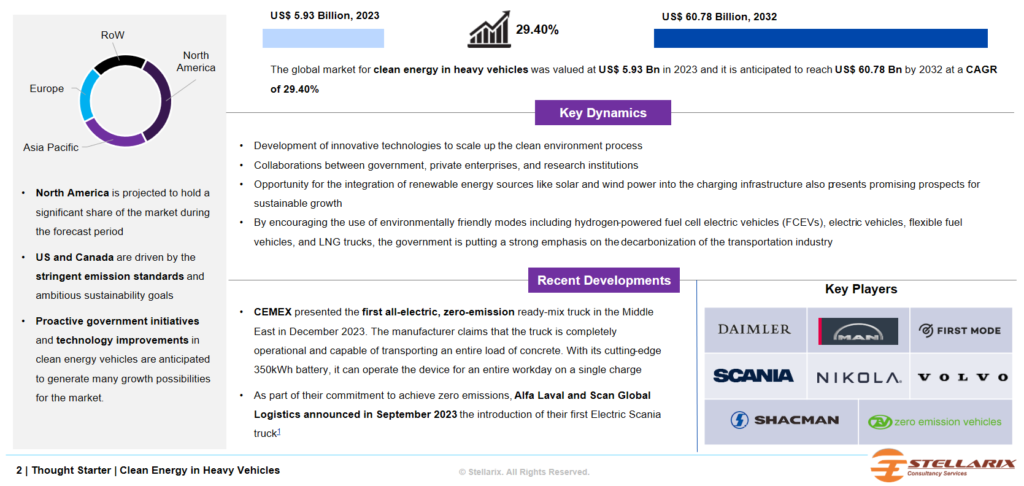

The market for clean energy heavy vehicles was worth US$5.93 billion in 2023 and may reach US$60.78 billion by 2032 with a CAGR of 29.40%. North America holds the majority share of the market due to its strict emission regulations and lofty sustainability targets.

CEMEX presented the first all-electric, zero-emission ready-mix truck in the Middle East in December 2023. The manufacturer claims that the truck is completely operational and capable of transporting an entire load of concrete. Its cutting-edge 350kWh battery can operate the device for an entire workday on a single charge.

BEV and FCEV produce zero GHG emissions, but the overall WTW efficiency of BEVs with 100% renewable energy generation is the highest compared to others.

Scania’s biogas engines with the gearbox (G25) and the rear axle from the Super-based powertrain offer 5% fuel savings, and with Bio-LNG or Bio-CNG, there will be a CO2 reduction of up to 90%.

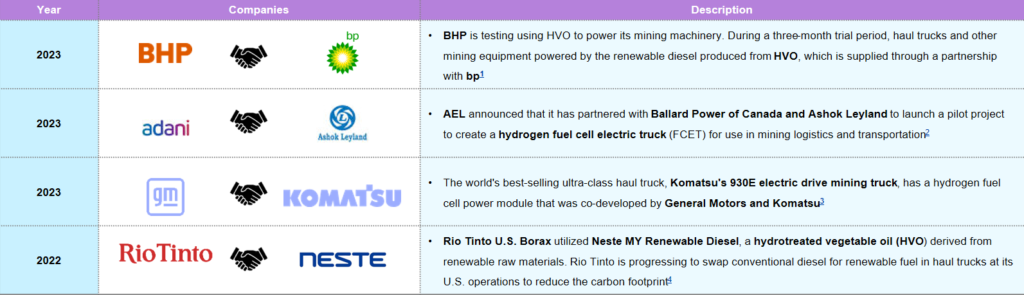

AEL announced that it has partnered with Ballard Power of Canada and Ashok Leyland for a pilot project for a Hydrogen Fuel Cell Electric Truck (FCET) for use in mining logistics and transportation.

Adapting to changes in the clean energy industry comes at a cost and general challenges, i.e., advancing in this domain where Scalability in alternative fuels, maximum payload proportional to average vehicle range, and providing charging or refueling infrastructure to support its continuous operations that enacts the proper foundation of clean energy in heavy vehicles.

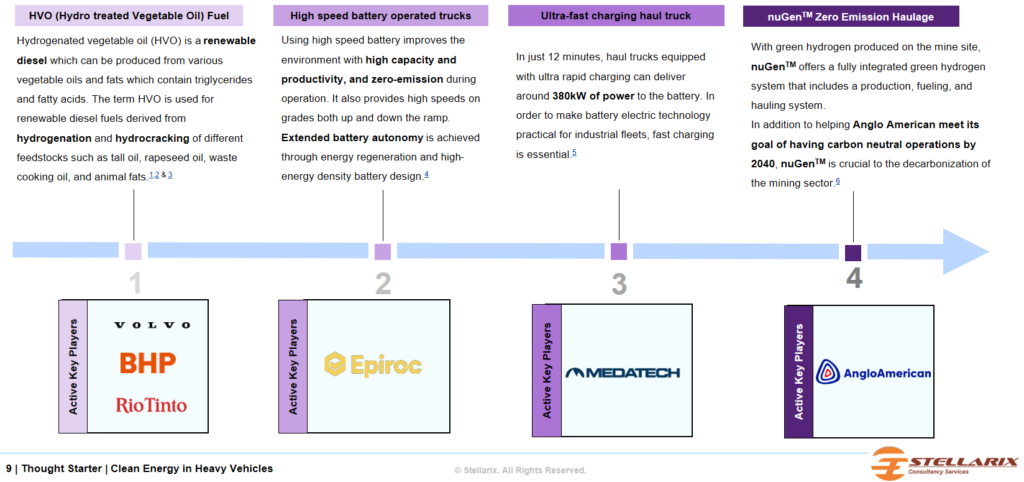

AngloAmerican’s NuGenTM Zero Emission Haulage offers a fully integrated green hydrogen system that includes a production, fuelling, and hauling system. The company aims to have carbon-neutral operations by 2040.

Rio Tinto U.S. Borax utilized Neste MY Renewable Diesel, a hydro-treated vegetable oil (HVO) derived from renewable raw materials. Rio Tinto is progressing to swap conventional diesel for renewable fuel in haul trucks. The Terren, a solar-powered truck by Aebi Schmidt, is versatile with rear-wheel steering and incorporates a 90 kWh battery for the 124-mile range, but the production model can accommodate 140 kWh for longer trips.

The technological research by the Federal University of Ouro Petro states the problems of high diesel oil consumption and increasing greenhouse gas emissions from mining operations. The study focuses on green hydrogen technology, which is produced from renewable energy such as solar and wind and is used in fuel cells or combustion engines as a renewable source.

The Mercedes-Benz GenH2 Truck achieved a range of 1047 km using a cell-centric fuel-cell system and one fill of liquid hydrogen tank.

With a charge of 12 minutes, Medatech haul trucks can deliver 380KW of power.