Sustainable Wastewater Treatment Technologies

Effluent treatment has long been the center of focus with respect to the demand for sustainability in industrial activities. However, over time, stakeholders realized that this myopic approach excluded the sustainability aspect of the processes applied for these treatments. Thus, the need to transition effluents or industrial wastewater treatment plants towards resource efficiency and sustainability emerged. Efforts are making strong strides in optimizing water, energy, and chemical consumption in nutrient extraction and removal of carbonaceous compounds. A few technologies that demonstrated the potential to sustain the ecological challenges of wastewater treatment plants are summarized below:

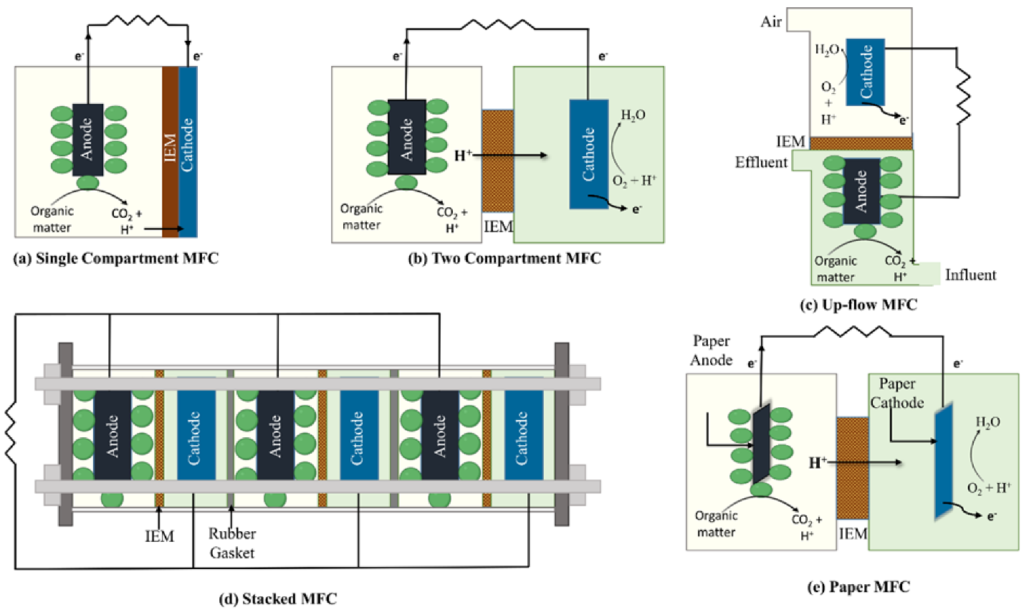

Microbial Fuel Cell:

Microbial fuel cells (MFCs) are proficient in turning chemical energy from industrial and civil effluent. Simultaneously, applying specific electroactive bacteria (EAB) turns chemical energy into electrical energy. Alongside this, it can impact the oxidant reduction and substrate oxidation reactions that tip the scales of energy and economics in favor of the wastewater treatment plant. Research suggests that the performance of MFCs can be further modified by optimizing operational parameters like applied electric resistance, hydraulic retention time (HRT), and organic loading rate (OLR). Currently, researchers are using several mathematical models to modify the design and process of these cells.

Image Showing Different Types of Microbial Fuel Cells

Anammox-based Nitrification – Denitrification:

Though biological denitrification is a recommended approach to nitrogen removal from industrial effluent, it is a high resource and energy-consuming task. It needs organic carbon and aeration, which leads to the generation of high quantities of biomass and GHGs, contradicting the very purpose of its application. Ammonax bacteria convert the nitrite and ammonium present in sludge into dinitrogen (N2) gas, considerably reducing energy and resource requirements.

The nitridation-anammox system is perfect for treating high-strength wastewater like digester effluents and anaerobically treated industrial effluents. It needs 60% less energy and 90% less GHGs than biological nitrogen removal processes. The only challenge is that it can’t yet be used for mainstream treatments for unidentified reasons. Several efforts are being made to resolve these reasons. The most noteworthy ones include managing the high nitrogen-to-carbon ratio to maximize the attainment of carbon-based energy. Additionally, performance improvement for low-strength wastewater and better retention of anammox bacteria are crucial aspects. Lastly, there is a focus on achieving more practical implementation of anammox processes in large-scale WWTPs.

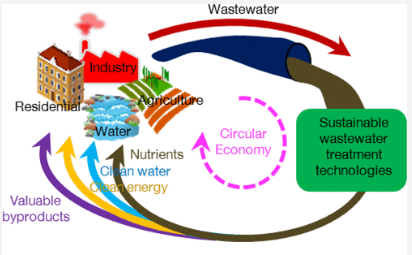

Codigestion:

It is a modified version of anaerobic digestion focusing on the circular economy of resources. The approach works well for both small and large-scale facilities. Several organizations are currently exploring this concept’s scope and benefits by extending the anaerobic digesters’ digestion capacity. The additional capacity of anaerobic digesters can help process higher-strength organic wastes. Codigestion is a highly lucrative process that helps digest FOG (fats, oil ma, degrease) wastes and transforms them into high-value products like biosolids, methane, etc. Technically and economically, it is a highly feasible technique; however, its economic viability still relies on several factors like organic waste characteristics, biosolids’ residual management costs, electricity costs, anaerobic digester capital costs, etc.

Circular Economy of Wastewater Treatment Plants

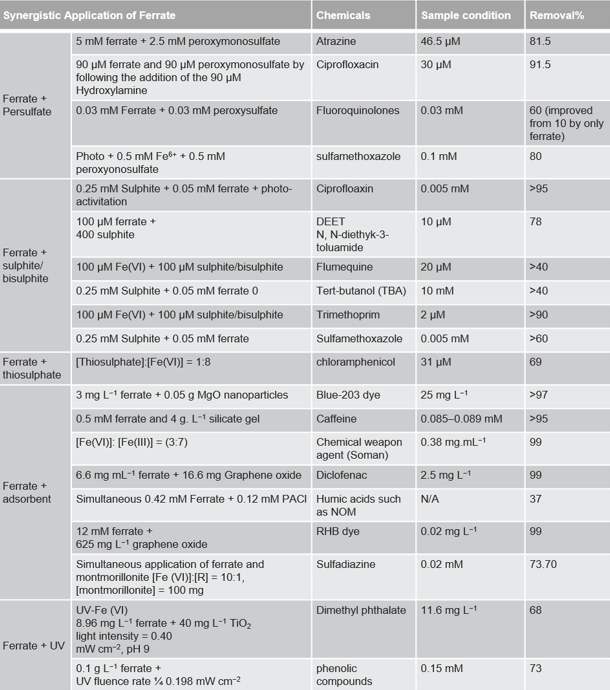

Synergistic Application of Ferrate:

Researchers have long demonstrated the efficient elimination of pollutants from wastewater using ferrate. However, the new approach to this concept calls for the synergistic application of ferrate with other useful measures like membrane separation, UV radiation, chemical additives, ozonation, acidification, etc. Research indicates a significant increase in the overall efficiency of water treatment when ferrate is applied synergistically.

It also mitigated other challenges like membrane fouling, less coagulation, lower levels of micropollutants’ biodegradability, deactivated or low formation of radical oxidative species, etc. However, the biggest challenge to this solution is Ferrate (VI) production in a preservable and stable form. Its shelf life is restricted to just a few seconds, making it highly unsuitable for commercial applications. However, a Dutch start-up, Ferr-Tech , developed a patented method to resolve this problem successfully. The synergistic application of Ferrate increases the energy efficiency and sustainability of wastewater treatments, thereby increasing water availability for reuse in industrial applications.

Various Ferrate Synergistic Applications For Removal of Micropollutants From Wastewater

Membrane Bioreactor System:

Membrane bioreactor systems, or MBRs, have wide applications in effluent treatment in the food and beverage industry. It is a constantly evolving domain with scope for improvement and great potential to resolve the contaminated wastewater challenge sustainably. As per a recent pilot study, both hollow fiber and flat sheet membrane bioreactors’ rejection rates exceed 84% for differing MLSS (mixed Liquor Suspended Solid) levels. These membranes significantly reduced COD (Chemical Oxygen Demand) and TSS (Total Suspended Solid) along a varying range of MLSS levels. It implies that the MBRs have great potential for sustainable chemical cleaning for food and beverage effluent.

Wastewater Hydroponics:

A slightly less researched domain, wastewater hydroponics, holds high scope in terms of sustainable effluent treatment, specifically concerning domestic, industrial, and municipal effluent. Wastewater hydroponics can remove microorganisms, pollutants, heavy metals, and every other kind of conventional pollutant through simple methods like phytoremediation. Nevertheless, several operating parameters like light duration, hydraulic retention time, influent concentration, plant selection, and pH heavily influence it. Developing a standardized evaluation index to assess the effectiveness of this method may yield fruitful and lasting results.

Conclusion

The technologies mentioned above are just a few expected to answer the challenges related to wastewater treatment plants. Most research and data suggest synergistic applications, such as integrating advanced membrane technologies with reverse osmosis. This integration might pave the way to address the demanding prerequisites of wastewater treatment plants’ sustainability issues. It may also give considerable attention to decentralized and modular systems. Additionally, integrating AI-driven solutions is essential to enable real-time adjustments, upgrade energy efficiency, and considerably constrict operating costs.