Intelligent Gripper Systems: Predicaments and Solutions

Robotic manipulation has long impended the path of automation of industrial robots. Its restrictive flair also interferes with integrating AI and ML in this domain, specifically concerning COBOT (COllaborative roBOT) applications, resource efficiency, and work environment safety. Industrial robots’ lack of mechanical and cognitive precision restricts their adoption in smart, multi-tasking manufacturing operations. Intelligent gripper systems offer a straightforward answer to most of these problems. However, most solutions are either in the research phase or commercially integrated into a single-task operation. There is an imminent need to understand these challenges’ most plausible solutions and keep the latest innovations in that niche in check. In this write-up, we have tried to summarize all three aspects from a technological point of view.

Challenge: The Impaired Cognitive Functionality

The Problem

Conventional heavy-duty robots lack the intelligence and adaptability to fit in the dynamic environment of Industry 4.0. To program them for a single task, one must handcraft multiple trajectories, which result in high costs, longer durations, and an error-prone modus operandi. These robots must customize the environment around them in a deterministic pattern where they position and place everything precisely. If the nature, dimension, or design of the product changes, it is necessary to recalibrate and reprogram the robots from scratch. Essentially, the robots lack perception, which prevents them from performing context-specific tasks. Even a simple task like pick-and-place requires object identification, locating the correct grasping point, optimum grasping and releasing force, and calculating the safest and shortest route to the destination.

The robot must analyze the size, weight, surface texture, and hurdles between the pick-up point and destination. It is challenging since the robot control method needs to include high-level abstraction with a description of objects that the robot needs to manipulate. Unless the robot has artificial senses like hearing, vision, and tactile motion, it will be as good as asking a blind person to cross a busy road.

Most Plausible Solutions

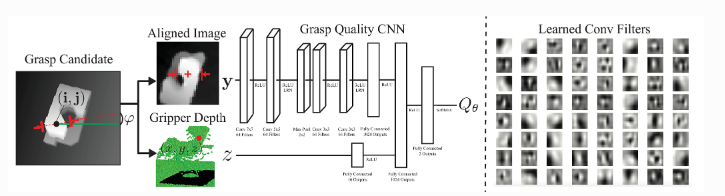

Solution 1: GQ-CNN Model: The Grasp Quality – Convolutional Neural Network (GQ-CNN) model can aptly answer the grasping force calculation and object identification issue with COBOTs. It ranks the grasping potential based on grasp strength. In this case, the grasp robustness represents the probability of grasp success predicted by mechanical models. The grasping apparatus calculates the regular force for the object identified by the robot as per a predefined threshold. The grip force is adjusted per the identified object through force control as the grasping apparatus comes in contact with it.

Image 1: The Original GQ-CNN Model Architecture From Dex-Net 2.0

Solution 2: Grasp Wrench Space (GWS) Analysis: Grasp Contact Modeling is performed to process the information pertaining to the grasping contact. Further, contact parametrization is used to obtain applicable contact forces and moments. The system performs wrench-based grasp quality metrics using force and moment information. This allows it to assess the grasp quality in terms of resisting external disturbance wrenches. The output obtained from this metric helps derive the grasp force according to the detected object. This, in turn, improves the gripper’s grasping ability.

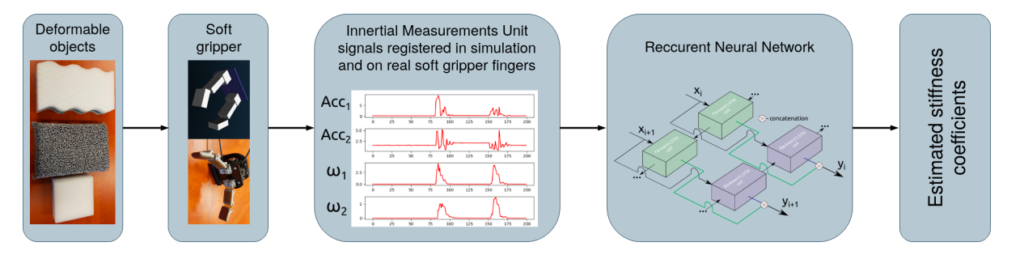

Solution 3: Using soft grippers and neural networks to render a tactile sense to the robot and estimate the object’s stiffness: In this method, the gripper fingers incorporate an Inertial Measurement Unit (IMU) for force calculation. A simulated environment generates the contact signals from the IMU, which also examines the soft gripper. It allows the user to perform the squeezing movement in both the simulation and the real world on objects with varied shapes and stiffness parameters. The results from the activity help the robot calculate the force required to hold the object and apply it to the gripper.

Challenge: Lack of Mechanical Precision

The Problem

Conventional robots use hard grippers that lack the feasibility of picking objects of varied geometric shapes and sizes. To resolve this problem, researchers are now using soft grippers. However, the challenge remains in automatically adjusting the grippers based on the size and shape of the detected objects. It is one of the biggest hurdles in developing intelligent or AI-based gripping solutions.

The Solution

Solution 1: Adaptive Control Algorithm: The gripper framework has plenty of room for embedded sensors that aid in detecting an object’s geometry. Additionally, the list of soft computing Support Vector Regression (SVR) and Extreme Learning Machine (ELM). The results yielded by sensors can help estimate optimal input displacements.

Image 3: Scientific Diagram of Adaptive Control Algorithm (PC: Researchgate)

Solution 2: Object’s Haptic Identification Through Modular Soft Robotic Gripper: The robot’s gripper equips every finger with a flex sensor that relays data in the form of a vector. The recorded data helps extracting the grasping configuration of the gripper. Thus, it will help produce a range of configurations for a range of grasps and objects coming in the way of the robot.

Solution 3: Soft Exoskeleton Covered Robot Finger With Tactile Sensors and Vision-based Proprioception: The exoskeleton-covered soft fingers with embedded cameras help obtain images of objects coming in the robot’s way. The under-actuated exoskeleton integrated with a cable-driven system helps actuate the gripper for various tasks. A well-trained proprioception CNN model helps to sense and categorize different object geometries. The neural network also classifies the profile and size of objects based on data relayed by embedded cameras. Also, the results yielded by the neural network help automatically adjust the soft finger.

Recent Use Cases

- Onrobot RG2: A Copenhagen-based gear manufacturer, Osvald Jensen introduced an Onrobot intelligent gripper solution that speeds up the overall task and modifies the machine shop’s productivity and performance. In addition, the Onrobot RG2 dual grippers resolve several challenges. They reduce the object picking and placement cycle time. Thus, improve the holding capacity of objects of all shapes and sizes. Additionally, they largely minimize human intervention

- Onrobot RG6: Incorporated by Tomenson Machine, these grippers play a key role in improving object identification and detection capabilities. Moreover, Obrobot RG6 grippers are helping Tomenson reduce misleading objects, thereby reducing infrastructural investment and better profitability.

Research Scope

- Eco-EGain Nanocomposite based smart grippers: A study was conducted on self-powered and pneumatically driven soft robotic grippers capable of recognizing the object in its path and avoiding false positioning and undetectable slipping of the object.

- Bioinspired Soft Swallowing Gripper for Adaptable Grasping: Based on the toy named Water Snake Wiggly (WSW) design, this gripper can averting itself inside out for feeding. This concept’s design, modeling, and preliminary tests can be checked out here.

- Soft Actuators based on Hydrogel Nanocomposites with Anisotropic Framework: In this project, a facile strategy was proposed to fabricate smart hydrogel with controllable anisotropic structure and respective deformability. Additionally, they fabricated a Poly (N-isopropylacrylamide) hydrogel as an actuator. Also, this was achieved through the asymmetric growth of a silver microdendrite network in the hydrogel matrix using a phototriggered electroreduction.

Final Word

The skill shortage and the rise in demand for product customization raise the need for intelligent industrial robotics solutions. Moreover, sustainable industrial operations also contribute to the increased need for intelligent gripper systems. Additionally, these solutions can quickly raise the level of sophistication and capabilities of industrial robots. Furthermore, most of these solutions are currently in the research phase. Still, when they move to the finalization or commercialization stage, they will help industrial operations meet expectations on each front.