Simplifying Vertical Farming To Answer Global Food Crisis

The exponential growth in global population will push the agricultural food production demands by 70% by 2050. It will also result in rapid global urbanization, which is expected to exceed 1200000 km2 by 2050. Therefore, the planners will need to ensure optimum land utilization to meet the increased food demand against the decreasing available arable land per capita. Though vertical farms have emerged as a potent solution, they still face multifaceted challenges in terms of implementation and upscaling. It is a resource, cost, and energy-intensive concept that has proved its worth only on pilot, prototype, and small scales. As a sustainable alternative, it carries immense potential to meet the increasing demand for organic food. However, the relative complexities and substantial research and innovation efforts need closer acknowledgment. Let’s understand the problem first before discussing plausible solutions.

Image 1: Graph Depicting The Tussle Between Global Population and Total Arable Land From 1950-2050

What Kind Of Challenges Restrict the Growth And Upscaling Of Vertical Farms?

The Cost-Benefit Conundrum

Vertical farming is a cost and energy-intensive process. It may optimize water, soil, and land usage, but the constant energy requirements and uber-high real estate prices raise the capital investment bar too high. These high costs raise the product process, which the end-user would accept only on the grounds of some special USPs or non-availability of the given product. To summarize, the present economics of vertical farming are more inclined towards high capital, operational, and post-operational costs that stand far ahead of the profits realized in the process. Even in the long term, it would take years to break even with the initial investment or annual costs, nullifying this concept’s appeal.

Image 2: A CAPEX Comparison Between Basil Production In A Greenhouse And An Indoor Urban Vertical Farm (IUVF)

High Energy Requirement

A NASA scientist, Bruce Bugbee, claims that vertical farms can overtake traditional farms only when they work in natural light. Power consumption is one of the biggest hurdles in the upscaling and growing controlled environment agriculture industry. An environmental writer, George Monbiot, calculated that the primary cost of supplementary light to increase the grain worth one loaf of bread in a vertical farm is approximately. $15. The cost breakdown doesn’t include just the lighting costs, but the constantly running HVAC systems that maintain optimal growing temperature, moisture, and airflow in the farms.

According to the 2022 UN-Habitat report, cities consume 75% of global primary energy, which implies that unless renewable sources of light and energy come into play, the idea of growing food in a controlled environment might remain a distant dream. Another issue is that artificial lighting releases a lot of unwanted heat that interferes with the humidity and air conditioning of the plants, leading to higher prices.

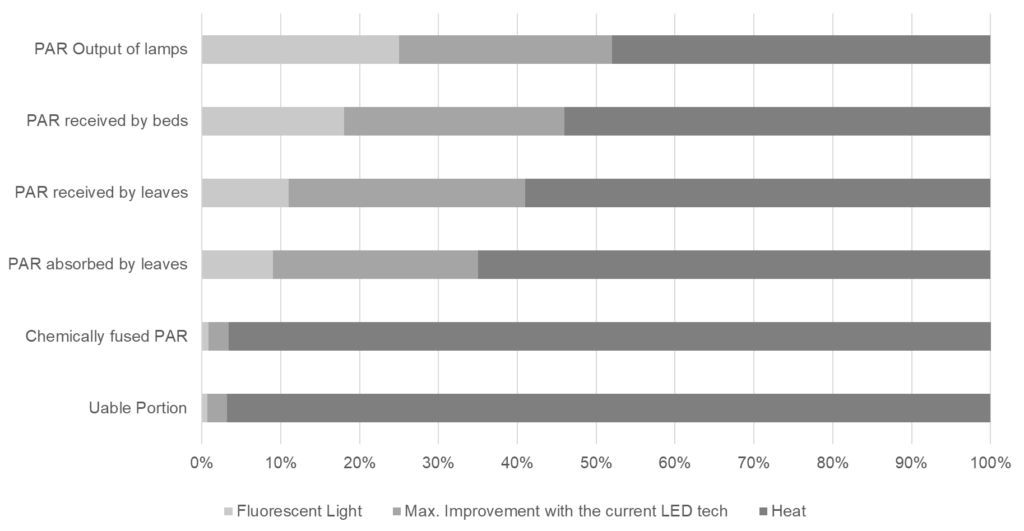

Inefficient Photosynthesis

Vertical farms have LEDs (Light Emitting Diodes) as the primary light source. These diodes offer higher conversion efficiency than their predecessors. However, the photosynthetically active radiation (PAR) is only from 400nm to 700nm, which implies that even the most efficient LEDs supporting plant cultivation convert only half of the supplied power to PAR. From that half, only a small fraction is used by the plant. Overall, artificial lighting decreases the photosynthesis efficiency of plants. The best achievable efficiency, to date, has been registered as 2.5%.

Restricted Crop Variety

One of the biggest hurdles in the growth and development of vertical farms is restricted crop variability. To date, it has only been able to grow microgreens, herbs, low-carb leafy vegetables, and small fruits like strawberries. The infrastructure, culture mediums, and equipment used in the process cannot support tall or thick plants, making them incapable of producing staple edibles like rice, wheat, maize, etc. This reduces their contribution to global food security and sovereignty problems.

What Kind Of Solutions Can Help Resolve These Challenges?

Automation:

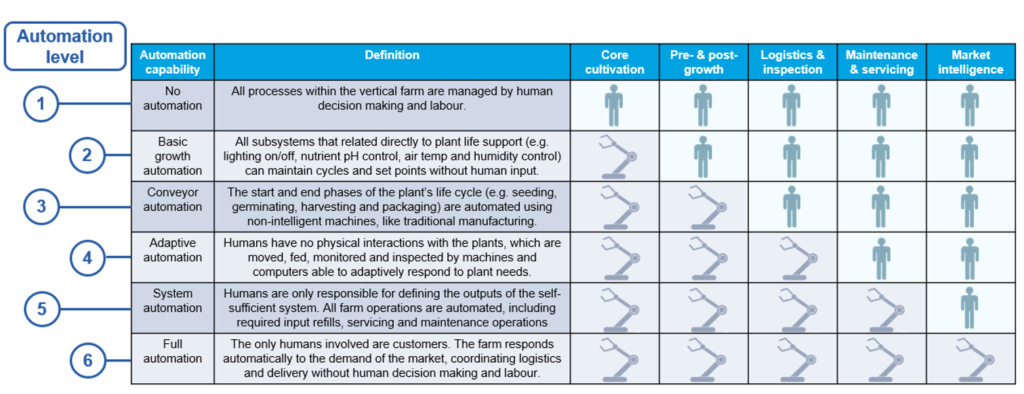

Automated Vertical Farms (AVF) can answer several major issues plaguing the growth and economics of vertical farming. The extensive sensor networks can monitor the growth of crops, optimize workflow, and reduce manual labor tasks. It can bring down several complexities, pinpoint problems, and even identify tasks that are difficult to automate. It includes basic maintenance activities and crop harvesting. Several companies offer, merge, and invest to integrate automation in the vertical farm. For instance, in 2021, AeroFarms partnered with Nokia Bell Labs to integrate automated crop monitoring systems with their vertical farm. Similarly, iFarm, a vertical farming technology provider, provides its proprietary StackGrow technology. It is an automated vertical farm system for predictable and energy-efficient cultivation of leafy greens and herbs.

Image 4 :Various Levels of Automation For Vertical Farm by iDTechEx

Crop Motion Technology:

A proprietary tech developed by CubicFarms moves plants to lights rather than using lights to grow plants. In the process, the motion tech moves the grow trays throughout the farm module on an undulating path that falls under a single line of LED lights. The single-lane LEDs are enough to provide the required light to plants even at temperatures of -40 degrees Celsius. As a result of this technology, the CubicFarms’ VF uses 54-62 percent less energy than its conventional counterparts.

Image 5: Crop Motion Technology

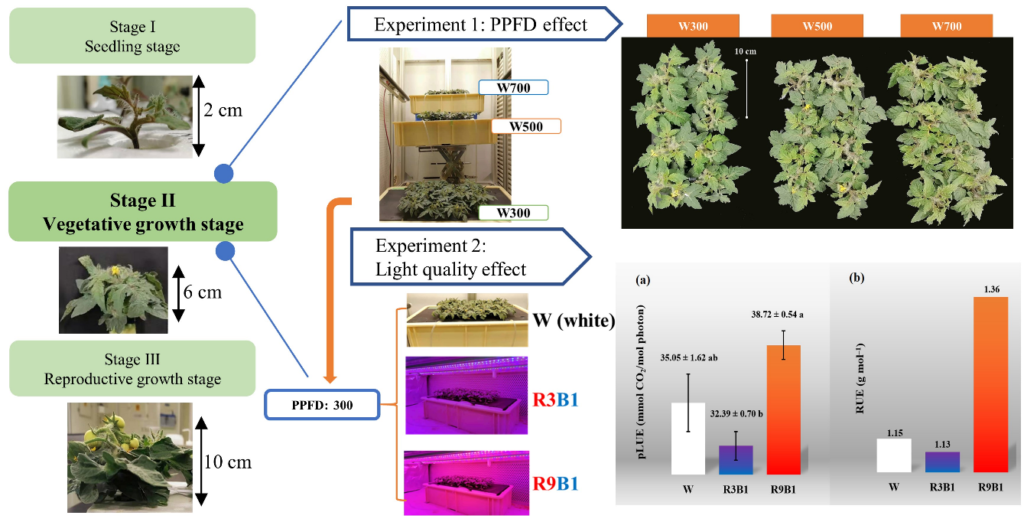

Improving Photosynthetic Photon Flux Density:

Photosynthetic Photon Flux Density (PPFD) can always be modified to improve the photosynthetic capacity of plants in vertical farms. For instance, in an experiment in a plant factory, the PPFD was enhanced by subjecting the plants to white light during the vegetative growth stage. The intention was to study the effect of white light and light quality with 300 µmol m-2 s-1 PPFD on radiation-use efficiency (RUE) and plant growth in the vegetative growth stage. They increased the PPFD, which led to an increase in photosynthetic rate while lowering the RUE. It was concluded that PPFD at 300 µmol m-2 s-1 and light quality at R9B1 (red: blue = 9:1) could improve the photosynthetic efficiency of plants at the vegetative growth stage while keeping up the levels of RUE.

Conclusion

Vertical farming has the potential to resolve the global food crisis in the coming years. However, substantial efforts are needed to improve its sustainability and cost-effectiveness. Controlled environment agriculture can only succeed when it is merged with some of the fundamentals of traditional agriculture. For instance, all activities are currently performed under artificial lighting, which is harmful and inefficient in many ways. Most of its challenges can be resolved if access to natural light is improved on farms for a better part of the day.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.