PFAS-Free Packaging for Sustainable Industrial Applications

The packaging industry is going through a rigorous change following health and environmental concerns and the need for sustainable materials to keep safety standards high. The campaign has led to the scrutinization of per- and polyfluoroalkyl substances (PFAS), the group of forever chemicals that are heat, stain, and water resistant and are comprehensively used in the packaging industry. The rising issues surfacing with links to PFAS and adverse effects have mounted pressure on regulatory bodies to enforce stringent regulations on PFAS packaging and promote PFAS-free packaging. This blog explores the latest developments, research, market trends, and industry responses to PFAS-free packaging.

Know About PFAS: Characteristics and Risks

PFAS are organic compounds that are exceptionally fluorinated and known for their indispensable use in several industries, including textiles, food packaging, and industrial coatings. However, despite several benefits like environmental resistance, PFAS are spearheading water and soil contamination and are even found in the bloodstreams of humans, which can be severely harmful as they are prone to bioaccumulation and non-biodegradable.

Documented Health Impacts

Several scientific studies have been documented that elucidate potential perils caused by the use of PFAS. Some of them include:-

- Hormonal Issues: PFAS can cause endocrine disruption by interfering with hormonal production, leading to diseases like reduced fertility and thyroid dysfunction in humans.

- Cancer Risks: As per the epidemiological research, prolonged exposure to PFAS can cause types of cancers like testicular cancer and kidney cancer.

- Developmental Effects: Any pregnant woman who continues in a longer exposure to PFAS can give birth to a child with defects or developmental delays

- Immunotoxicity: Evidence emerging from studies suggests that PFAS can minimize the efficacy of vaccines by reducing the immune system responses.

Why Transition to PFAS-Free Packaging is Imperative?

Dumping the use of PFAS is not merely a regulatory issue but a market-driven necessity and, on top of that, an ethical one for humans. Also, the rising global sustainability needs, initiatives, and consumer awareness are making accelerated shifts in the domain:

- Expectations of Consumer Safety: Increasingly high awareness regarding chemicals in packaging materials offer to users.

- Sustainability Goals: Various industries are making quick moves to adhere to practices that are environmentally friendly.

- Brand Reputation: Businesses are bidding to adopt PFAS-free packaging to add a prime differentiator to their brand reputation and edge ahead in the competition.

Current Alternatives of PFAS: Exploring Viable Substitutes

Identifying a suitable alternative to PFAS is a task that needs scalability, balancing functionality, cost-efficiency, and proper strategies that can serve the purpose seamlessly. The following points deeper dive into the top PFAS-free solutions:

- Silicone and Clay Nanoparticles: These substances have the potential to enhance resistance to moisture and grease without adding toxicity found in PFAS. They are commonly used as barrier enhancers for the same reason. Also, their low migration perils make them adaptable to strict safety standards.

- Bio-Based Coatings: These coatings provide grease and water resistance properties sans toxic leachables and are extracted from renewable sources like starches, proteins, and waxes. They exhibit compliance with recycling systems and are most useful in compostable packaging. Moreover, they also showcase application versatility and thermal resistance as per research.

- Cellulose-Based Films: The source of deriving these films are plant fibers, which offer comprehensive barrier properties against oxygen and moisture. Interestingly, nanocellulose is emerging as a leading material in this category. It is biodegradable, lightweight, and provides durability.

Industry-Specific Implications and Progress

PFAS-free packaging is leveraging progress amidst implications in various industries. Here are a few:-

Healthcare and Pharmaceuticals:

Healthcare and pharmaceutical industries require top-notch standards. Thus, any packaging must ensure chemical stability, environmental concerns, and sterility. Several manufacturers are testing PFAS-free containers and wraps that are durable during extreme temperatures during prolonged storage.

Food and Beverage:

The F&B industry has a lot riding on it as it has to ensure environmental responsibility while maintaining food and beverage quality. Greaseproof papers and compostable packaging are growing as benchmarks, and collaboration between material innovators and food companies is displaying accelerated growth.

E-commerce:

The industry delivers several packets globally, and with the brands progressing and finding space in the market, call for biodegradable packaging, cushioning, and recycled fillers to keep the carbon footprint lower. These materials offer better packaging alternatives while retaining essential packaging properties.

The Regulatory Landscape: Shaping Industry Actions

European Union: PFAS restrictions are happening courtesy of the EU’s REACH framework, which is trying to ensure a significant phase-out by 2030.

United States: To expand the list of its TSCA (Toxic Substances Control Act), the US EPA (Environmental Protection Agency) is assessing the situation to exclude PFAS and rope in the alternatives. States like Maine and California have already drafted legislation for banning PFAS.

Global Developments: Global organizations like UNEP are taking initiatives for collaboration among nations to resolve the PFAS contamination issue on an international scale. These efforts aim to facilitate seamless cross-border trades in biodegradable materials or better alternatives while harmonizing regulations.

Challenges in PFAS-Free Adoption

The PFAS+free packaging is needed, but transitioning is not that smooth, and conditions and situations pose significant challenges or barriers that need to be overcome while establishing the seamless adoption of PFAS alternatives.

- Cost and Scalability: It is one of the biggest deterrents for PFA-free packaging, especially SMEs, which find it difficult to adopt following the high production and developmental costs.

- Performance Challenge: Manufacturers have a hard time identifying new materials that can suit the performance of different industries in terms of safety benchmarks, including non-migration, heat, and water resistance.

- Infrastructure Gaps: The infrastructure has to be fast-tracked to create a widespread facility for better testing and certifications related to PFAS-free materials globally and current unavailability, slowing down adoption and innovation.

These challenges can be conquered with mundane strategies that include collaboration between private and public sectors, research and development institutions, and people with the acumen to resolve packaging issues.

Future Trends: Innovating Beyond Compliance

The blend of technology, innovation, and sustainability with PFAS alternatives is making the future look brighter:-

Circular Economy Models:

The market is up to grab recyclable and reusable materials for packaging. PFAS-free designs offer the opportunity to integrate the idea and create a circular economy model that can dominate the market while keeping the environment clean.

Smart Packaging Technologies:

IoT sensors can converge with PFAS-free materials, allowing real-time monitoring of logistics and food freshness, improving customer experience and safety.

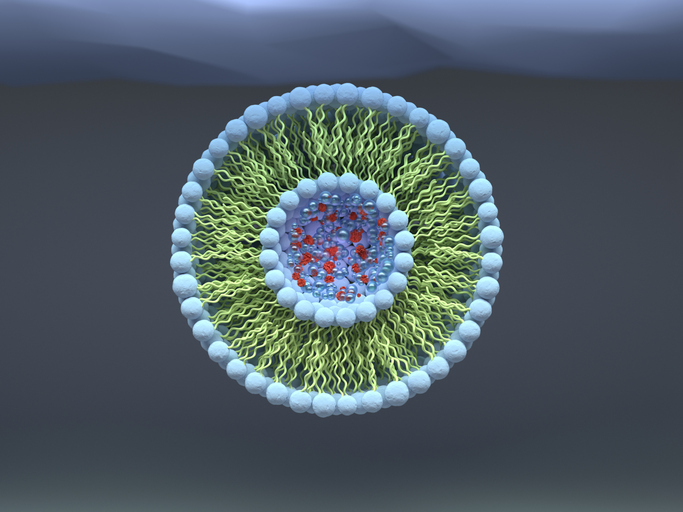

Nanotechnology Advancements:

Nanotechnology is creating a strong wave in favor of PFAS-free packaging, with nanomaterials enhancing the properties of materials and minimizing the carbon footprint and pollution. Moreover, their versatility and lightweight make them prime candidates for next-generation solutions.

Startups Offering PFAS Alternatives

1. YUTOECO– The startup specializes in plant fiber packaging solutions and has developed three PFAS-free molded fiber catering packaging options, including dip-coating, lamination, and additive in pulp. These solutions feature qualities like temperature, water, and grease without compromising the existing production lines.

2. Celebration Packaging introduced the EnviroWare series, including PFAS-free compostable packaging from white bagasse fiber. The products rolled out by the company have been honored by TÜV Home Compostable certification, confirming functional qualities like microwave reheating capabilities while ensuring biodegradability.

3. Detpak: The startup has created the Vanguard® range by Eco-Products®. It uses proprietary alternative compounds for grease and oil resistance sans harmful PFAS chemicals.

4. Duni Global: The company’s range includes boxes, takeaway bowls, and plates that comply with current regulations and are safer for food packaging. The startup’s approach exhibits the industry’s shift toward safer alternatives.

Conclusion

PFAS in packaging has been there for a long time and has caused irreparable damage to people and the environment. Thus, phasing it out is a quintessential step toward healthy and sustainable practices. The packaging industry and manufacturers are at the forefront of bringing the required change and innovating with time, adhering to demand and regulations. Researchers are joining forces with regulators to overcome technical and economic hindrances to provide a clear mandate.

Businesses are adopting PFAS-free packaging to improve brand recognition among targeted consumers. This move aligns with the future and respects people’s demands for innovative and sustainable packaging materials, creating a greener future for all stakeholders in the value chain.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.