Industry 5.0: Imparting Soul into a Mechanizing World

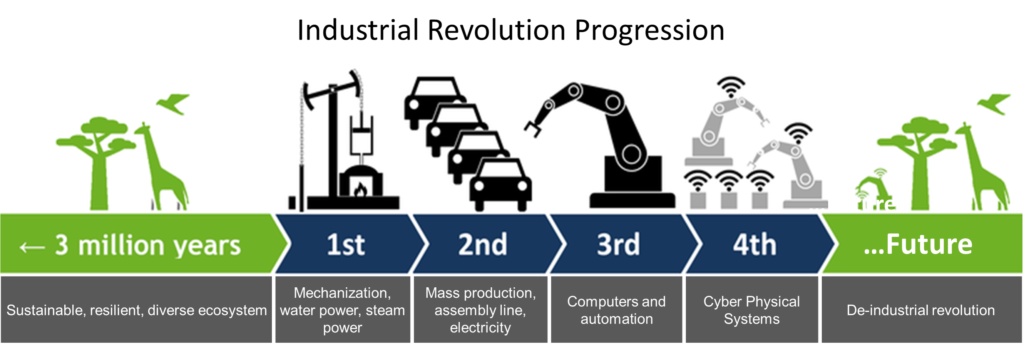

Human evolution and technology have a straight equation with each other. This relationship and the rising mechanization through subsequent industrial revolutions can be traced throughout history. We are currently passing through the initial phase of Industry 4.0. It centralizes on “Smart Production” that shifts the technological paradigm from embedded systems to Cyber-Physical Systems (C.P.S.). There is a dynamic move from centralized to decentralized production, and Industry 5.0 will bring a paradigm shift.

The key drivers of this revolution are IoT, Big Data, Cloud Computing, AI, and robotics. As interesting and acceptable as it may sound, the inadequacies of this shift are apparent to those whose vision is fixed on a sustainable future devoid of ethical conundrums. But that’s where the need to look beyond Industry 4.0 arises.

How is Industry 4.0 the Precursor To Industry 5.0?

A study published in 2015 indicated that most Small and Medium Enterprises (S.M.E.s) around the globe fail to acknowledge the relevance of Industry 4.0. The cost of deploying ultra-sophisticated technologies like big data, IoT, and robotics might be feasible for big corporations, but SMEs are at a disadvantage. It stands true even after seven years.

Then, there is the social aspect, where increased automation is dissolving job opportunities instead of creating new ones. This invalidates the real intent of bringing Industry 4.0 to the table.

There is broad skepticism about the rising dependence on I.T. systems for every small task. It may strengthen the technology sector, but cross-domain implications are yet to be predicted. Several other unknowns need to be considered. For example, the juggernaut of gathering behavioral data from every end poses a potential threat to privacy and safety irrespective of the harmless good intentions of enterprise owners. It amounts to the foundation of a “Surveillance Capitalism” that may have more negatives than positives in the near future.

All these loopholes, combined with a great dearth of respect for our environmental conditions, bred ground for a more evolved and ethically synergetic industrial revolution that would restore the currently lost balance between development and sustainability, hence, Industry 5.0.

Figure: Industrial Revolution Progression

Introducing Industry 5.0

Industry 5.0 will be a step ahead of Industry 4.0. It will work beyond connecting devices with each other. It will allow collaboration between humans and robots on factory floors and replace standard robotic production with automated production. “Cobots” – machines collaborating with human operators will replace robots.

Some researchers think that it will be the age of the bioeconomy, where renewable biological resources will be produced, converted, and upcycled to yield value-added products like bioenergy, bio-based products, feed, food, etc. Unlike Industry 4.0, where major developments will be witnessed in the I.T. sector, equal measures of progress will be seen in ecology, life sciences, food sciences, agronomy, enabling technologies, industrial technologies, I.C.T., and tacit & local knowledge base.

Another vision of Industry 5.0 states the efficient utilization of machine and human workforce within the boundaries of this planet. The path will be traced back from a virtual to a real environment. The industrial world will improve on Logistics Efficiency Design (L.E.D.) principles, a model devised to redefine global supply chain efficiency. It aims to neutralize the waste generated by the contemporary buyer-supplier interaction and inculcate more transparency, efficiency, and profit sharing along the supply chain. Its Principles are famously known as the 6Rs, which include Recognition, Reconsideration, Realization, Reduction, Reuse, and Recycling of available resources.

Our Key Insights for Future of Mobility

Alternative to Li-ion Batteries | Hydrogen Powered Vehicles | EV Charging Stations |

Biodegradable Plastics For vehicle interior

The Concept

The academic world has been pushing the concept of the Fifth Industrial Revolution since 2017. The European Union recognized this term in 2021 after discussions with research groups, technological organizations, and funding organizations.

The concept of Industry 5.0 acknowledges the industry’s potential to become a resilient creator of prosperity while maintaining our planet’s natural ecosystem and keeping human needs at its core. It will complement the ongoing Industry 4.0 and transform it into a human-centric and sustainable Industry. This approach will shift how value is created, distributed, and exchanged in the socio-economic world. It will meet the pressing need to support societal goals.

The emergence of Industry 5.0 will open gates to various value-driven technological developments, including:

- Personalized human-machine interaction through technologies that reconcile human and machine capabilities

- Smart bio-manufacturing and recyclable materials embedded with sensors, scanners, and health monitors

- Digital cloning and simulation of entire systems

- More efficient data analysis, storage, and transmission technologies can tackle system interoperability

- Better integration and incorporation of artificial intelligence in decision-making, sensible automation, and error reduction in complex systems

- More energy-efficient, autonomous, renewable technologies that simultaneously reduce manual labor and ecological burden

Key Technologies Driving Industry 5.0

Here is an in-depth exploration of the key technologies propelling Industry 5.0:

1. Big Data Analysis:

Industry 5.0 harnesses the power of Big Data Analysis as a cornerstone for informed decision-making. Organizations extract actionable insights by processing and analyzing massive datasets, enabling them to optimize operational processes and enhance strategic decision-making. This data-centric approach forms the bedrock of Industry 5.0’s drive toward intelligent and adaptive manufacturing systems.

2. Internet of Things (IoT):

Industry 5.0 enables real-time data exchange and automation by seamlessly connecting devices and systems. This interconnectedness improves operational processes and catalyzes enhanced productivity. IoT integration empowers industries to create responsive, self-optimizing ecosystems where devices communicate intelligently, fostering a dynamic and interconnected industrial environment.

3. Collaborative Robots:

Industry 5.0 embraces the deployment of Collaborative Robots, or cobots, to augment human capabilities in manufacturing and beyond. These robots are designed to work alongside human operators, enhancing overall efficiency and safety. Cobots liberate human workers to focus on tasks requiring creativity, adaptability, and critical thinking, thereby contributing to a more harmonious man-machine collaboration within industrial settings.

4. Digital Twins:

The concept of Digital Twins emerges as a powerful tool for optimization. Organizations can thoroughly comprehend their operations by developing virtual duplicates of physical processes, products, or services. Digital Twins facilitate performance optimization, predictive maintenance, and iterative improvements without disrupting real-world processes. This technology enhances agility and adaptability in complex industrial systems.

5. Artificial Intelligence :

AI-powered systems automate tasks, enabling a shift from rule-based to intelligent decision-making. Industry 5.0 guarantees the automation of routine and time-consuming tasks by implementing machine learning, natural language processing, and other AI applications. It empowers human professionals to concentrate on high-level, strategic activities, fostering a symbiotic relationship between human expertise and AI-driven efficiency in the evolving industrial landscape.

What Lies Ahead of Industry 5.0?

Industry 5.0 will indeed be instrumental in converging human and machine worlds in a synergetic fashion, but it will bring the need for domain-specific research to the surface. The cross-domain flow of data will remain an unresolved mystery, and so will the coupling of different technologies for more efficient delivery of products and services. Areas like portable medical diagnostics, bionic organs, co-morbidity cures, commercialized computing, E.E.G., deep dive technologies, and extended reach of quantum computing in the mainstream world will be some fundamental dynamics that will enforce the need for Industry 6.0. Achieving a balance between sustainability and technology will solve only one part of the giant puzzle. Improving the overall quality of life will become the core of the research and hypothesis.

There is already a word about Industry 6.0, but how about we discuss that in the next blog?

How Can We Help?

To stay afloat amid major paradigm shifts, every business must identify scalable opportunities through innovation, value creation, and a strategic road map to these goals. With over a decade of experience, Stellarix has also supported hundreds of clients in achieving these goals with a comprehensive 360-degree horizon scan, current and future landscape visualization, and extensive market research.

We can be your partner on the road to strategic growth and a sustainable future. To know more, please refer to our contact details.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.