Thermo-Acoustic Refrigeration

Refrigeration technology has advanced greatly since the beginning of the 19th century, revolutionizing food and storage techniques for medical purposes and industrial applications. Traditional refrigeration methods, which mostly rely on vapor compression cycles, have encountered new challenges and constraints, such as environmental pollution, poor energy efficiency, and intricate apparatuses. TAR has recently been developed as a sophisticated technique compared to its traditional prototype. TAR systems employ high-pressure sound waves in a gastight passage to transfer heat and achieve refrigeration without utilizing refrigerants.

Thermo-Acoustic Refrigeration Phenomena

First of all, to explain how a thermo-acoustic device operates, one needs to comprehend the features of the considered acoustic waves, with particular attention paid to the pressure and velocity fields of the longitudinal waves. In these waves, particles vibrate up and down in the direction of wave propagation, leading to changes in pressure as the waves compress and are rare. These pressure variations are important for thermo-acoustic application and are employed for cooling and, hence, associating the acoustic wave motion with refrigeration. These waves need a material substance like air or water for their propagation; therefore, they cannot pass through a vacuum.

How Thermo-Acoustic Refrigeration Work?

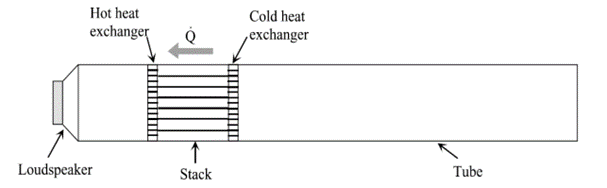

The Thermo-acoustic Refrigeration System consists of a loudspeaker acting as a driver connected to an acoustic resonator (tube) filled with gas. Inside the resonator, there is a stack made up of several parallel plates and two heat exchangers.

Methodology

- The driver (loudspeaker) is one of the major components, as it creates high-intensity sound waves.

- When the sound wave from the acoustic driver passes through the resonator at a particular frequency, pressure pulsations form a standing wave, causing the gas in the resonator to move back and forth along the tube. This movement, combined with the pressure pulsations, leads to heat transfer when the gas comes into contact with the stationary stack.

- As a result of the expansion and compression of the gas due to the sound, heating and cooling occur at both ends of the stack, creating a temperature difference through the thermo-acoustic effect.

- The reduced temperature at the cold end of the stack is extracted using a heat exchanger and can be used for refrigeration purposes.

Comparison of Thermo-acoustic Refrigeration and Traditional Refrigeration

| Aspect | Traditional Refrigeration | Thermo-acoustic Refrigeration |

| Working | Based on the vapor compression cycle | Based on the thermo-acoustic effects |

| Refrigerant | Use harmful refrigerants like ammonia, CFC, and HFCs | Use refrigerants like helium or nitrogen |

| Moving Parts | It relies on moving parts such as compressor | Minimal moving parts primarily rely on sound waves |

| Maintenance | Moving parts like compressors require lubrication, which increases maintenance | Minimal maintenance due to fewer moving parts |

| Environmental Impact | Harmful refrigerants can cause ozone layer depletion and global warming | Reduce greenhouse gas emissions and ozone depletion by eliminating harmful refrigerants with helium or nitrogen |

Effect of Working Fluid

In thermo-acoustic refrigeration, inert gases are highly effective because they are efficient and environmentally friendly. The cooling ability depends on how fast sound travels through the gas; faster sound means better cooling. Inert gases typically have high sound speeds. Additionally, when the gas can transfer heat well, cooling is made easier by thickening the layer where heat is transferred.

Material for Stack

The Stack is called the heart of a thermo-acoustic refrigeration system because the heat transfer phenomenon occurs only within the stack. Using materials like copper, nickel, or stainless steel, which have high thermal conductivity, can cause a problem. This leads to the system conducting heat back to the cold side, essentially undoing the cooling effect. To prevent this, the stack material should have lower thermal conductivity and higher specific heat capacity than the gas. Among the materials used, Mylar or BoPET (Biaxially-oriented Polyethylene Terephthalate) stands out for several reasons-

- It possesses low thermal conductivity and high heat capacity, making it suitable for efficient heat transfer. It is readily available in sheet form.

- Another reason Mylar is favored is that the spacing between the stack layers is very small. Traditional machining methods struggle to create such precise dimensions.

- Mylar comes in extremely thin sheets, making it easy to roll into a spiral stack configuration, which suits the compact spacing requirements perfectly.

Current Research & Innovation

- Prof. Luo Ercang from the Technical Institute of Physics and Chemistry (TIPC) of the Chinese Academy of Sciences has developed an innovative heat-driven thermos-acoustic refrigerator (HDTR) with a novel bypass configuration to eliminate the temperature-matching constraint, significantly improving efficiency.

- Gree Electric Appliances Inc. of Zhuhai is working on a pulse thermo-acoustic refrigeration device and refrigeration equipment, which converts the kinetic energy of the moving part into sound energy and converts the sound energy into heat energy through the pulse refrigeration tube.

- BYD Co Ltd. provides a refrigeration device for a vehicle that collects the heat and noise of the vehicle and then drives the thermo-acoustic refrigeration system to provide cooling.

Application of Thermo-Acoustic Refrigeration

- Space Exploration: Thermo-acoustic refrigerators cool the electronic components of the space exploration rover. The advantages of using thermo-acoustic systems are that they have no moving parts, which makes them simple and reliable, and they are efficient and comparable to conventional systems.

- Computer Chips: Due to its simple operation and use of only one moving part, thermo-acoustic refrigeration is suitable for cooling the latest generation of computer chips.

- Medical Storage: Thermo-acoustic refrigeration, due to its simplicity and affordability, utilizes atmospheric air as the working medium, making it an environmentally friendly choice for storing medical necessities.

Advantages of Thermo-Acoustic Refrigeration

The advantages of Thermo-acoustic refrigeration (TAR) are explained below:

Limitations of Thermo-Acoustic Refrigeration

- Efficiency: Thermo-acoustic refrigeration is currently less efficient as compared to traditional refrigeration.

- Less familiar: They are less familiar, as they are relatively new and not widely adopted in the market.

- Vibration: Thermo-acoustic produces unwanted vibration.

- Sealing: Thermo-acoustic systems require proper sealing.

- Power Density: The power density of the Thermo-acoustic refrigerator is lower than that of traditional refrigeration.

Key Players

Lihan’s Thermo-acoustic technology utilizes an oscillating piston driven by a linear motor to generate high-frequency pressure waves, creating an acoustic wave within the system. Gas moves back and forth inside the system depending on the tuning mechanisms. Proper phasing between gas displacement and pressure waves enables heat to be pumped from the cold region to the ambient, providing cooling power.

Equium harnesses its thermo-acoustic technology to reduce CO2 emissions by 80%. Acoustic waves are autonomously generated and amplified within machines, either by temperature gradients or electricity. These waves perform compression and expansion similar to a piston in a thermal engine or compressor, allowing highly efficient heat transfer without moving parts or using greenhouse gas refrigerants.

BlueHeart Energy is currently a global leader in the field of thermo-acoustics. Thermo-acoustics presents an entirely different method for generating heat and cold. It achieves this by compressing and expanding helium, which always remains in a gaseous state. Since there is no phase change involved, the system is not constrained by any specific condensation temperature, enabling it to operate efficiently with a wide range of temperature inputs and outputs.

Environmental Impact & Sustainability

As energy demand increases, so do concerns about its excessive use and negative impacts on the environment and natural resources. Thermo-acoustic refrigeration systems offer a solution by using inert gases such as helium or nitrogen instead of traditional refrigerants, which can be environmentally harmful. By avoiding these refrigerants, thermo-acoustic systems help reduce greenhouse gas emissions and ozone depletion. These systems are also quieter because they rely on acoustic waves rather than mechanical compressors or pumps, minimizing noise pollution and improving comfort in residential, commercial, or industrial settings. Furthermore, thermo-acoustic systems can be easily integrated with renewable energy sources like solar or waste heat, reducing dependence on fossil fuels and enhancing sustainability efforts.

Future Prospects

- Adoption of this technology could lead to a significant decrease in energy consumption within commercial refrigeration systems, offering substantial cost savings on energy bills for businesses.

- By eliminating the use of refrigerants with polluting emissions, this technology has the potential to mitigate up to 10%-20% of global warming by the year 2050, particularly in commercial refrigeration systems.

- Using superior materials, such as materials with high heat capacity, and working fluids, such as inert gases, can help to improve efficiency.

Conclusion

Thermo-acoustic refrigeration is a revolutionary technological model of cooling that is non-chemical and eco-friendly as opposed to ordinary refrigeration techniques. By integrating effective principles in thermo-acoustics, this article shows how thermo-acoustic systems can be a valuable step towards phasing out greenhouse gases and attaining energy efficiency. However, ongoing research and development strategies ensure that thermo-acoustic refrigeration is on the cusp of changing the face of cooling and preservation of food in addition to medicine and other perishable commodities with reduced environmental effects.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.