Unlocking Value: The Strategic Imperative of Polyamide Recycling

The Polyamide Paradox: A Critical Environmental Challenge with Untapped Potential

Polyamide (PA), a highly versatile and widely used synthetic polymer, is integral to numerous industries, from textiles to automotive components. Despite its widespread use, the material presents a significant environmental challenge due to its inherent persistence and slow degradation. When discarded, polyamide objects persist in the environment for extended periods, contributing primarily to global plastic pollution. This environmental continuity underscores the critical need for effective recycling. The current landscape of polyamide recycling reveals a significant gap.

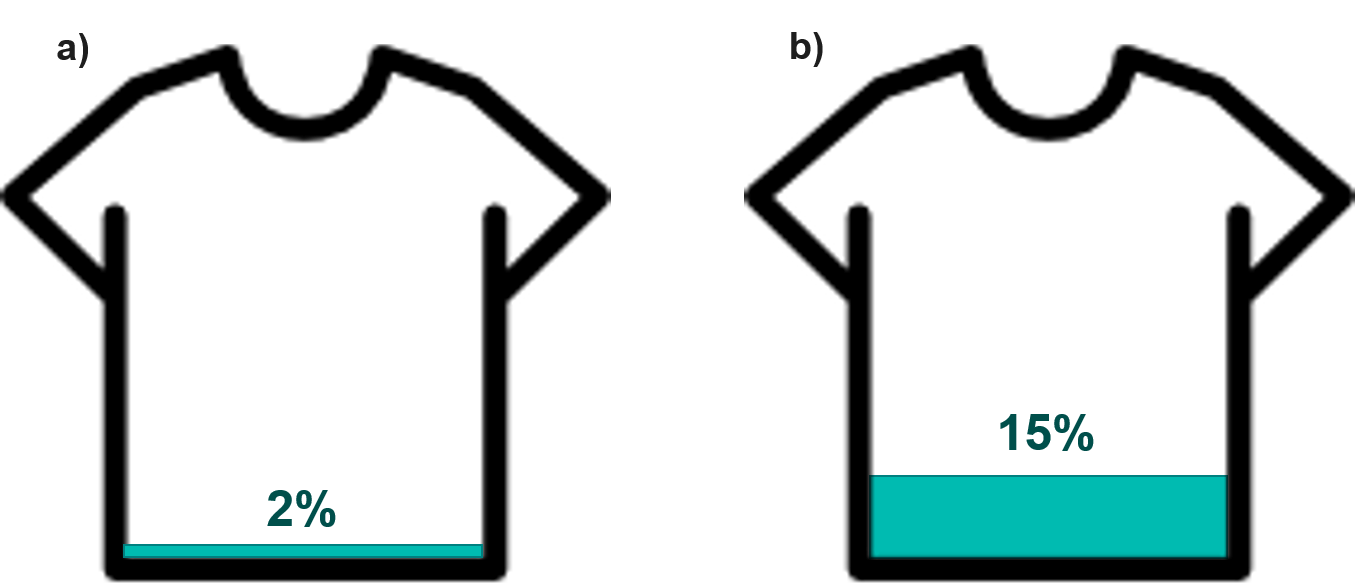

In 2019, only 2% of the total 5.58 million tons of polyamide produced globally originated from recycling processes. This figure stands in stark contrast to other synthetic fibers, such as polyester, where recycled polyester made up 15% of total global polyester production.

This extremely low polyamide recycling rate highlights a significant waste stream that is largely ignored. This environmental liability turns into a huge market opportunity for companies. The significant unrealized feedstock potential, reflected in the 98% difference between current recycling rates, suggests a move away from conventional waste management toward the value-add of an underutilized but valuable resource. The analogy to polyester highlights polyamide’s inferiority, indicating significant potential for industry innovation and expansion, which will draw businesses ready to take the lead in sustainable materials.

A Booming Market: Recycled Polyamide Driving Sustainable Growth

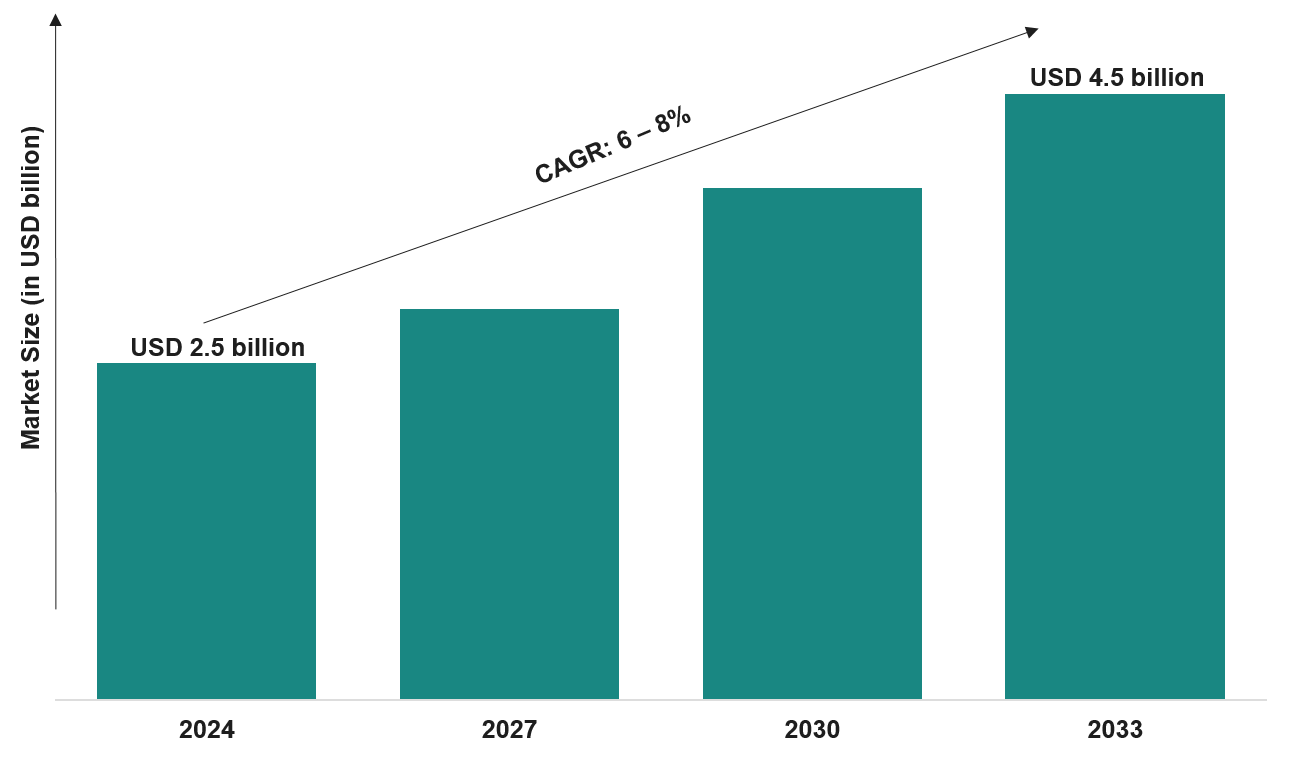

A significant shift in the global sustainability landscape toward sustainable materials is reflected in the strong growth of the worldwide recycled polyamide market. This demand, valued at approximately USD 36 billion in 2023, is expected to grow at a steady compound annual growth rate (CAGR) of about 6-6.5% from 2024 to 2031, reaching roughly USD 40-45 billion by 2030. This growth trend indicates strong, ongoing demand for recycled polyamide across sectors. In particular, the Recycled Polyamide 6.6 (PA6.6) Market is expected to grow at a compound annual growth rate (CAGR) of approx. 6-8% from its 2024 valuation by 2033. For B2B clients seeking reliable, expanding supply chains, this growth is an alluring offer because it is motivated not only by environmental goodwill but also by direct responses to real business drivers and mounting regulatory pressures. More than 50% of significant end-user industries are switching from virgin to recycled PA6.6 without sacrificing performance or durability, and more than 54% of businesses have already introduced sustainable products based on PA6.6.These market forecasts highlight recycled polyamide’s long-term feasibility and profitability, establishing it as a key component for further advancement.

Key Drivers: Industry Demand & Regulatory Imperatives

The increase in demand for recycled polyamide stems from industrial and regulatory requirements, as well as sustainability goals. The demand for recycled polyamide has increased across sectors such as automotive, textiles, and electronics, driven by its excellent material properties. The push for recycled polyamide comes from the following drivers:

- Industry Demand: Recycled polyamide demand is intensely concentrated in high-performance sectors, with the automotive industry accounting for 37–40% as manufacturers replace heavier metals for better fuel economy and EV components. The electronics industry contributes another 28% and relies on its superior durability and thermal stability. Meanwhile, in the textiles sector, the brands and consumers push for durable, sustainable polyamide textiles (e.g., Adidas × Parley Swimwear Collection), expanding demand in apparel.

- Regulatory Imperatives: Government regulations and policies from North America and Europe led to industries from these areas to adopt recycled polyamide, with more than 40% of regional industries adding recycled polymers as policy-driven compliance, which was supported by a 33% expansion in recycling infrastructure.

- Corporate Sustainability Initiatives: The corporate push for adopting more sustainability practices has also played an important role in the adoption of recycled polyamide, with more than 50% of key industries adopting it to meet compliance and long-term environmental commitments.

- Environmental Benefits: Adaptation of recycled polyamide, emissions from industries were >33% lower compared to the conventional process.

- Strategic Advantages: The adoption of recycled polyamide provides companies with strategic advantages in various stages, such as market access, regulatory compliance, and positioning themselves as leaders in innovation-driven sectors, as sustainability becomes a core determinant of future industrial success.

Quantifiable Environmental Advantages: A Greener Footprint

1. Energy Savings and Operational Efficiency

Using recycled polyamide has significant and measurable environmental advantages that result in a more environmentally friendly operational footprint. Up to 60% less energy is used in the production of recycled nylon than in the production of virgin nylon. Lower operating costs for businesses are a direct result of this decrease in energy consumption.

2. Reduced Carbon Footprint and Emission Cuts

In addition to saving energy, recycled polyamide has a significantly smaller carbon footprint. When applied to glass fiber-reinforced polyamide waste, for instance, advanced pyrolysis techniques can halve the global warming impact compared to traditional pyrolysis techniques. More generally, major sectors have achieved emission reductions of more than 30% thanks to production lines that switched to using recycled input materials. When compared to traditional materials, chemically recycled polyamide, like PA6, also exhibits a noticeably smaller impact on climate change, which in turn supports corporate climate goals and can provide a competitive edge in markets where carbon regulations are becoming more stringent. For example, the production facility of ECONYL® is powered entirely by renewable energy, and for every 10,000 tons of ECONYL® regenerated nylon produced, 65,100 tons of carbon emissions are avoided.

3. Resource Conservation and Waste Reduction

Recycling polyamide is essential for conserving resources and reducing waste, as it helps divert large amounts of waste from landfills and oceans, thereby reducing pollution. Making virgin nylon requires a lot of water, which can lead to water shortages and wastewater pollution, but recycling helps reduce these problems. Also, recycling one ton of nylon can save about 6-8 barrels of oil, helping preserve important non-renewable fossil fuels. Each year, programs like Healthy Seas recover over 1,000 tons of nylon fishing nets from the oceans, preventing marine pollution and turning waste into a valuable resource.

These are measurable metrics that directly improve operational efficiencies and reduce environmental liabilities for businesses; they are not just theoretical ecological claims. Reducing waste demonstrates responsible resource management by lowering disposal costs and supporting the circular economy. These benefits go beyond simple compliance and provide a clear return on investment for using recycled materials.

Cutting-Edge Recycling Processes: Unlocking Polyamide’s Full Potential

Waste polyamides can now be recycled into high-quality materials that are frequently on par with virgin polymers thanks to advancements in recycling technologies. These cutting-edge procedures are intended to tackle the difficulties that come with recycling polyamides, including their high melting points and the complexity of mixed waste streams. We offer tailored guidance on selecting and implementing the most suitable recycling technologies for your specific requirements. Mechanical Recycling: It is an economical and sustainable approach, especially for uniform post-industrial waste. Polyamide is shredded, dried, melted, and then re-extrusioned into new products. By combining it with virgin material or adding chain extenders, the quality of the recycled material can be preserved or even improved.

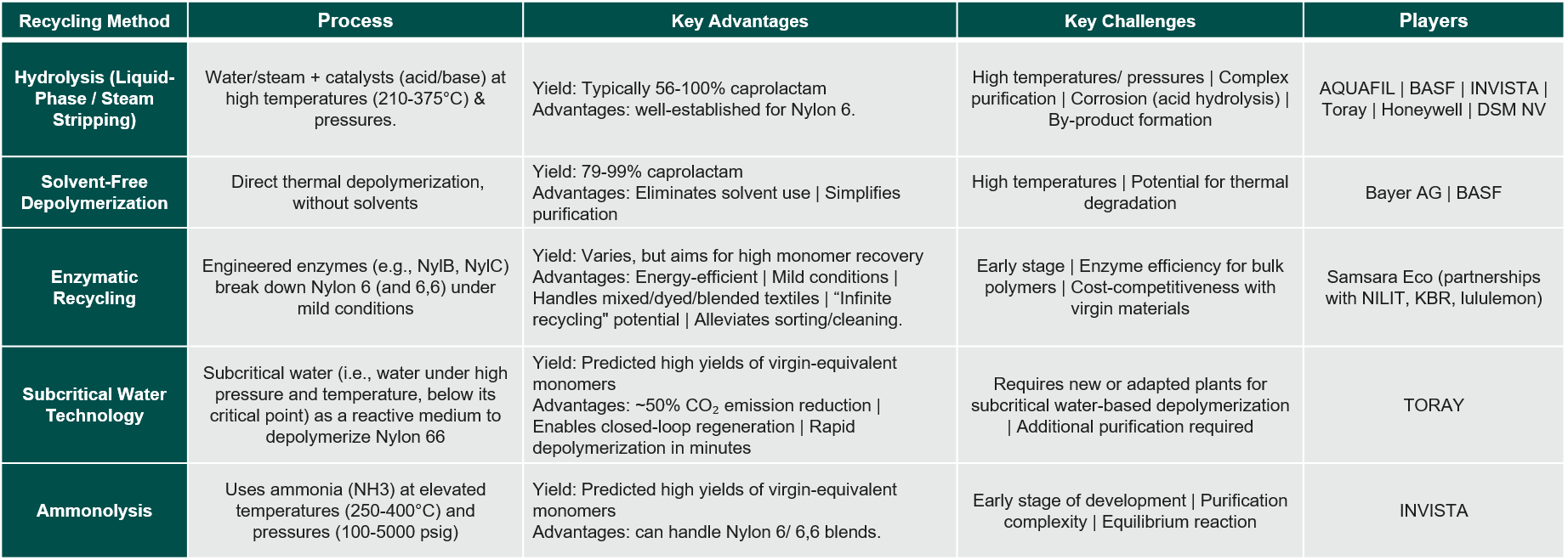

Chemical Recycling: This allows for the production of new, virgin-equivalent nylon by disassembling polyamide into its basic monomers or chemical constituents. This method is essential for recycling non-recyclable plastics, such as films and laminates, formerly, and works in tandem with mechanical recycling to close the gap between the petrochemical and waste management sectors. Key chemical recycling approaches include:

- Hydrolysis: In this process, polyamides are broken down into their element monomers, including caprolactam. For illustration, the only large-scale system for depolymerizing post-industrial and post-consumer nylon at the moment is acid hydrolysis.

- Enzymatic Depolymerization: This innovative fashion breaks down nylon 6 and nylon 66 by using enzymes that have been specially created. The capability of enzymatic processes to handle complex feedstocks, such as mixed, multicolored, or spandex-blended fabrics, offers a significant advantage. This allows for potentially” horizonless recycling cycles” without immolating material quality. Companies like Samsara Eco are leading the way in developing this sustainable technology.

- Ammonolysis: This method uses ammonia at high temperatures to break polyamide polymer chains (PA6 or PA6.6), producing virgin-equivalent monomers in a yield of almost 100%. For instance, INVISTA is working hard to develop this technology for post-consumer waste nylon.

Diverse High-Value Applications: Performance without Compromise

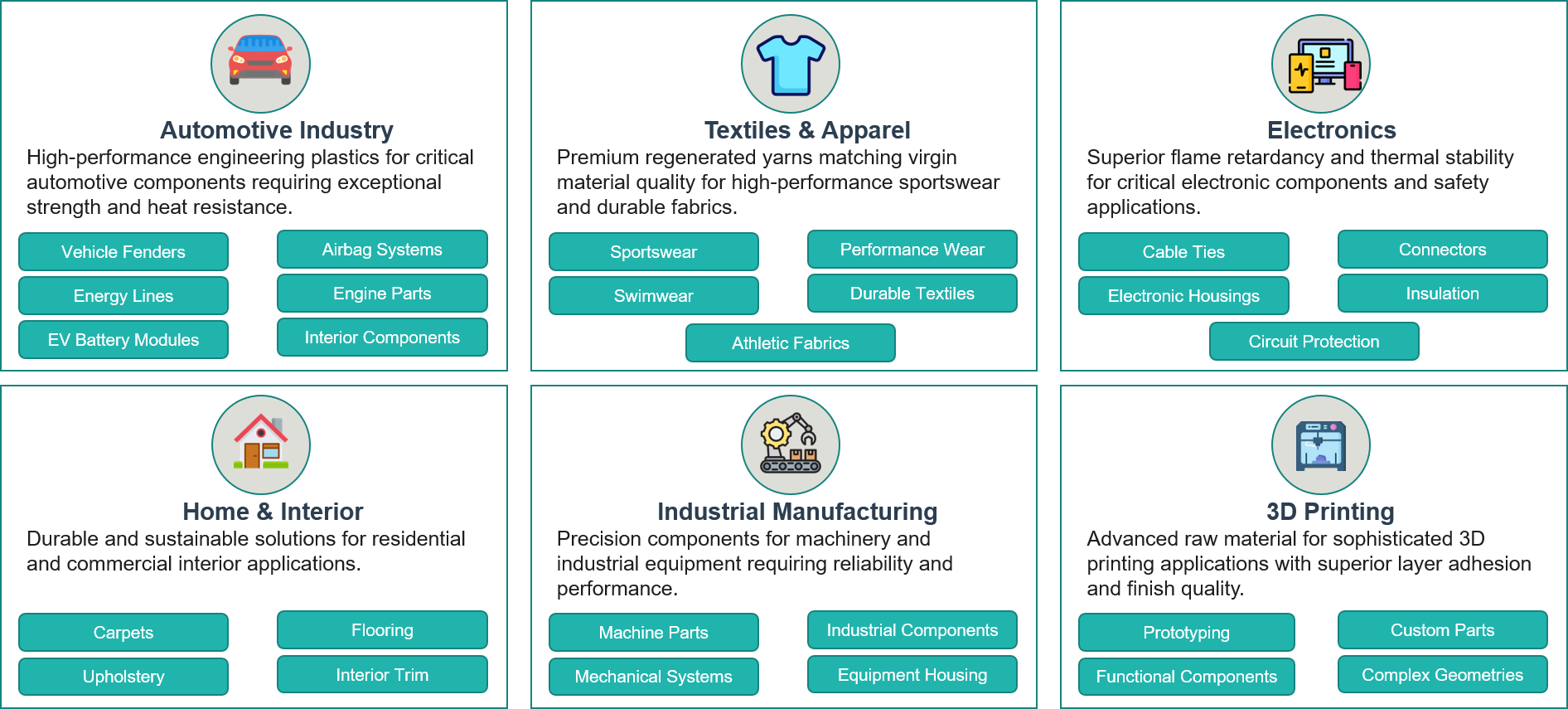

Recycled polyamide is a high-performance material suitable for demanding tasks across various fields. Due to its lower cost, it can serve as a substitute for virgin components. We assist you in identifying different applications for recycled polyamide in your product line.

- For Automotive Sector: The recycled polyamide is considerably employed in high-performance engineering plastics for corridor-like vehicle fenders, airbag systems, energy lines, machine corridor, electric vehicle (EV) battery modules, and other interior components. Its natural strength, heat tolerance, and durability are pivotal in these operations.

- For Electronics Sector: The electronics assiduity benefits from recycled polyamide’s honey retardancy and thermal stability, which make it perfect for string ties, connectors, and electronic jackets.

- For Textile Sector: Regenerated yarns for sportswear, swimwear, and other long-lasting fabrics are made from recycled polyamide and continuously match virgin material in terms of quality and functionality.

- Other Sectors: In addition to these primary sectors, recycled polyamide is used in carpets, artificial ministry corridors, and indeed as a raw material for sophisticated 3D printing.

This section directly addresses potential concerns about the quality or limitations of recycled accoutrements by highlighting specific, high-performance operations. As demonstrated by its widespread use in various diligence processes, recycled polyamide is not only an eco-friendly choice but also a practical, high-performing option for essential needs. The material’s versatility and the strong possibility for B2B clients to easily incorporate it into their existing product lines are further emphasized by the wide range of applications.

Conclusion

The analysis highlights a pivotal moment for polyamide in the era of global frugality. Although polyamides’ continued use has historically been profitable in specific applications, their slow degradation and low recycling rates have become a serious environmental concern. However, this challenge is rapidly evolving into a significant market opportunity. This shift is evident in the growing demand for recycled polyamide, which is expected to exceed USD 50 billion by 2030, driven by strict global regulations and rising demand from high-value industries such as electronics, automotive, and textiles.

Using recycled polyamide offers additional advantages beyond its environmental friendliness. Functional improvements and reduced environmental impacts are directly linked to measurable benefits, including up to 60% in energy savings and over 33% in CO2 emissions reductions compared to virgin products. Economically, incorporating recycled content enhances supply chain flexibility, protects against fluctuations in virgin material prices, and significantly boosts sustainability credentials and brand reputation, especially as B2B buyers increasingly value environmental responsibility and transparency.

High-quality, abecedarian-original recycled polyamide can now be produced from complex waste aqueducts thanks to technological advancements in recycling processes, such as advanced mechanical, chemical (hydrolysis, enzymatic, ammonolysis), and dissolution methods that are overcoming literal constraints. This ensures that performance is maintained, making recycled polyamide a viable, high-performing material for essential operations in various industries. The widespread and growing use of recycled polyamide in demanding applications confirms its effectiveness and establishes it as a vital component for a sustainable future.

Thus, supporting recycled polyamide is not only a responsible choice for the environment but also a strategic business necessity for fostering innovation, resilience, and leadership in the ever-changing global market. Forward-thinking companies are already adopting sustainable practices by using circular materials. At Stellarix, we help companies capitalize on this opportunity by providing tailored solutions at every step, from sourcing recycled polyamide to understanding technological advances and connecting with the right partners, giving them a competitive advantage from all angles.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.