Adhesives And Sealants

Stronger bonds and innovative solutions for tomorrow's needs

Advanced Adhesives and Sealants For Evolving Market Needs

The packaging, transportation, and construction industry will primarily drive the growth of the adhesives and sealants sector. The key to sustaining market shifts is adopting sustainable products like biobased and VoC-free adhesives. Adapting to Industry 4.0 norms and controlling costs through this shift will be a key differentiator. The rapid shift to sustainable business practices includes an increased focus on water-based technologies while reducing focus on solvent-based technologies and the development of renewable/bio-based adhesives. However, cost remains one of the main parameters in technology selection, implying better financial strategies are needed. This conundrum is leading to a rising inclination toward industry 4.0 technologies that can reduce manufacturing downtime, improve the reliability of hardware/equipment, and help find affordable alternative raw materials. Our adhesives consulting team is helping companies simplify these complexities with their market expertise and experience.

Industry Trends

Adhesives & Sealants Industry Trends

Smart Adhesives

VoC and PFAs Free Adhesives

Self-Adhesive Materials

Bio-Based Adhesives

Superhydrophobic Adhesives

Smart Adhesives

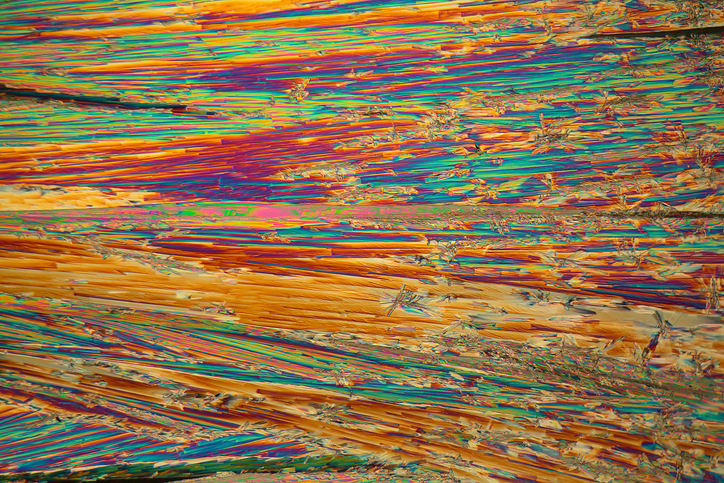

The momentum in the smart adhesives domain is currently dominated by several technological developments, including smart materials like semiconductor adhesives, intelligent adhesive bonding, and water-based and degradable adhesives. Innovation trends will keep inclining towards sustainability and expanding the cross-industrial applications of adhesives in the medical, construction, and electronics industries. The development of epoxy resins, nano-enhanced resins, and advanced materials resins will further shape the future of these products.

How Can We Help?

The transformation of chemical and materials industry in the coming years will be guided by agility to digitalize, sustainable sourcing, and ability to optimize resource utilization. The market lead will be shaped by success in application and opportunity mapping and innovation in decarbonization efforts. It implies an imminent need for experienced and resourceful counselling that could provide strategic guidance for adaptation, innovation, and harnessing the full potential of opportunities presented along the way. We have worked with almost all subsectors of this industry ranging from petrochemicals to additives, paints, coatings, agrochemicals, and biochemicals. We are well-equipped with experience and skills to reimagine operations from sourcing to upcycling to accommodate the changing dynamics of global chemical business.

ExploreAlignment with emerging sustainability standards and changing client preferences demands Research and development (R&D) prowess in the chemicals and materials industry. At Stellarix, our R&D and innovation strategy is meticulously crafted to navigate the dynamic realm of chemicals and materials. Focusing on market analysis, emerging technologies, and regulatory landscapes, our strategy promotes competitiveness and sustainable growth.

We thrive on collaboration and partnerships, engaging with research institutions and industry allies. A customer-centric approach tailors products to market demands, agile R&D processes ensure adaptability and data analytics enhances decision-making. We prioritize intellectual property management, practice sustainable supply chain integration, and excel in market entry and commercialization. Our risk management, continuous improvement, and global perspective ensure strategic alignment with international trends.

ExploreWe specialize in crafting dynamic business and market strategies for the chemicals and materials industry. Our holistic approach considers market dynamics, competition, tech trends, and customer needs. From market research to target markets, we guide you in identifying trends, developing tailored products, and optimizing your portfolio. We emphasize a clear value proposition, ensuring your unique offerings stand out.

Stellarix excels in innovation, technology adoption, and optimization of distribution channels. We help with pricing strategies and brand positioning and integrate sustainability and corporate responsibility seamlessly. Customer relationship management is a forte, and we explore global expansion opportunities. Our risk management expertise covers market fluctuations, supply chain disruptions, and regulatory changes. We guide strategic opportunities and due diligence in mergers and acquisitions (M&A). Establishing monitoring and adaptation mechanisms with defined KPIs, we adapt your strategy for continued success. Choose Stellarix to navigate the chemicals and materials industry strategically.

ExploreWe prioritize a robust chemical and materials sustainability strategy, aligning environmental, social, and economic factors for long-term success. Our approach involves key elements, including life cycle assessments, responsible raw material sourcing, and green chemistry practices to minimize environmental impact. We focus on waste reduction, water efficiency, and product innovation for sustainability. Carbon footprint reduction and adherence to certifications and standards are priorities.

Continuous improvement is embedded, ensuring regular assessments and seeking opportunities for enhancement. Choose Stellarix for a sustainable future in the chemical and materials industry.

ExploreCollaboration and partnerships drive innovation and boost competitiveness in the dynamic chemicals and materials industry. Our concise guide for co-manufacturing (co-man) and partner identification aligns with business goals in the chemicals and materials industry, emphasizing clear collaboration objectives. We identify partners with complementary technologies through a thorough assessment of organizational capabilities, market analyses, and technology assessment. Stellarix advocates engagement in industry networks and conferences to expand partnership horizons.

To ensure reliable collaborations, we focus on supplier and customer relationships, regulatory subordination, financial stability, and cultural compatibility. Our guidance covers risk assessments, legal considerations, and due diligence for flexible and scalable partnerships.

ExploreWith Stellarix, you can navigate the complexities of startup scouting and acquisition strategies specific to the chemical and materials industry. Our strategic support and guidance are helping companies bridge the gap between their business objectives and performance improvement. Our tailored insights based on extensive research and analytics have helped several key industry players in identifying emerging technologies and potential partners to stay ahead of the curve.

ExploreOur Experience

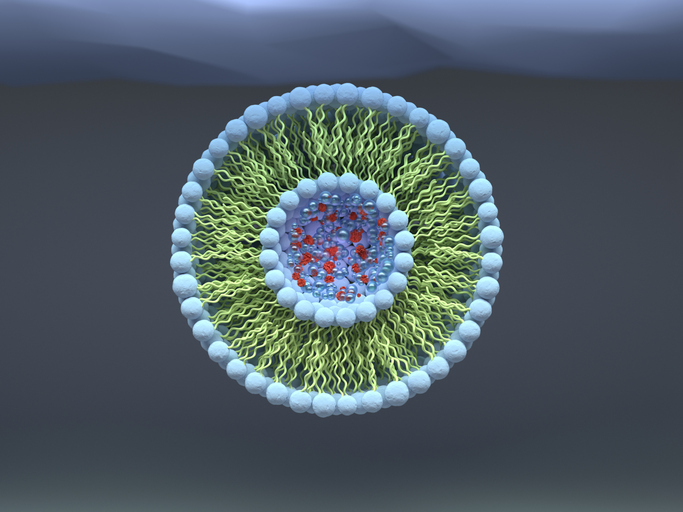

Technology Landscape – Biodegradable Capsule Suspension

A renowned C&M industry client engaged Stellairx to assess the global technology landscape for bio-based encapsulation to determine potential market opportunities and reinforce its market position. The insights provided by our chemical consulting team helped the client devise a strategic roadmap for future collaboration and market entry, thereby enhancing business resilience. Client Background: A global […]

Player Landscape – High Performance Polymers (HPP)

A leading player in the polymer segment sought a comprehensive overview of the high-performance polymers market to strengthen their strategic position. The strategic intelligence provided by our team allowed them to: Client Background: Our client is a leading player in the polymeric segment and wanted to explore the current landscape of high-performance polymers and their […]

Textile Value Chain Analysis– Assessing the Scale of Regenerated Cellulosic Fibers

A textile industry player sought to analyze the entire textile value chain to identify emerging technology trends, strategic entry points, and collaboration opportunities across each segment. The comprehensive market intelligence from Stellarix guided the organization’s partnership, investment, and innovation strategies, enabling long-term growth and competitive advantage. Client Background: The manmade cellulose fibers, commonly known as […]

Client Queries Addressed

Q1. How are advancements in automated dispensing systems, such as robotics, improving the precision and efficiency of adhesive applications? Q2. What innovations in curing technologies, like UV and LED curing, are reducing processing times and energy consumption? Q3. How are new application techniques contributing to developing adhesives and sealants for high-tech industries like aerospace and electronics?

Q1. How do lightweight adhesives and sealants contribute to electric vehicles and other sustainable transportation developments? Q2. How do adhesives and sealants improve vehicle safety, fuel efficiency, and overall performance? Q3. How are innovations in bonding technologies addressing the unique challenges of next-generation automotive materials, such as composites and advanced alloys?

Q1. What specific adhesive and sealant materials are being developed to bond with renewable energy substrates such as solar panels, wind turbine blades, and energy storage systems? Q2. What are the customer needs specific to the renewable energy segment? Q3. What innovations are improving the durability and longevity of adhesives and sealants used in offshore wind turbines and desert solar farms? Q4. What market segments within the renewable energy sector present the most significant opportunities for adhesive and sealant innovation?

Insights

See All

Blogs

Articles

Articles

Blogs