Industrial Future safety is the foundation of everything, and employers, safety officers, and statesmen will agree that this is ‘no exaggeration.’ The usual signboard stating ‘wet floor’ or another with the message ‘watch your head’ are all small ways to prevent accidents. Well-intended and deftly incorporated safety measures convey that 98% of industrial accidents are inevitable.

For office workspace safety, measures such as placing signs like ‘restricted access’ for data centers, using biometric-enabled entry to ensure safe offices, and accident mitigation steps like smoke detectors ensure the best preventive measures are in place. Statistics record that most industrial accidents are caused by human error and equipment failure.

Industries with different manufacturing types and production lines require special safety measures. Employers must provide workers with safety gear appropriate to their level of hazardous work, ensuring that their PPE is readily available at all times to prevent any work debacles.

Industrial Future Safety: Losses Amounting to Occupational Hazards

The International Labor Organization (ILO) estimates that globally, 2.3 million men and women lose their lives due to work-related accidents yearly, which totals 6000 deaths every day. Additionally, 340 million occupational accident cases and 160 million people at work battle work-related illnesses annually. Due to work accidents, organizations suffer disruptions, loss of credibility, financial loss, and even legal actions.

Accidents can lead to mishaps within work premises and even cause severe damage to the surroundings and fellow residents. Comprehensive work safety for industries comprises employee protective gear, regular site maintenance, predictive and preventive measures, and the use of future tech to mitigate such losses.

Industrial Future Safety: State and International Regulations

Employers are responsible for on-site employee safety. To ensure workplace safety, organizations must actively prevent occupational hazards such as safety threats, biological risks, physical harm, chemical perils, and overall climate damage. Globally, the International Labor Organization (ILO) and many similar specialized occupational safety bodies provide practical guidelines to businesses.

The Occupational Safety and Health Administration (OSHA) sets regulations and guidelines to ensure safety compliance in the USA. Likewise, agencies like the Canadian Center for Occupational Health and Safety (CCOHS) in Canada, the Health and Safety Executive (HSE) in the UK, the European Agency for Safety and Health serves in Europe, Japan Industrial Safety and Health Association (JISHA) works in Japan, Finnish institute of occupational health carries research in Finland and these bodies all work towards scientific research about prevention of industrial accidents and occupational diseases. The employer complies with all the key EHS guidelines and directives.

Industrial Future Safety: Advanced PPE Suits for Professionals

When on-site staff work in chemicals, manufacturing, or an industrial environment, they must have the right personal protective equipment. Agile and dependable organizations understand employee needs; their PPE suppliers/contractors are often the industry’s best. Specific PPE garments are necessary for medical professionals, pharmaceuticals, and heavy manufacturing industries like mining, transportation, aerospace, defense, shipping, steel, oil, or gas.

Employees who work in a still more precarious environment like working with cytostatic drugs, asbestos, radioactive waste, high quantities of caustic soda/ sodium hydroxide, sanitary and phytosanitary (SPS) products, inflammable & asphyxiant propane, concrete, and plaster additives with calcium oxide, crystalline silica or chromium that are corrosive/ abrasive to human tissue, biohazards like contagion waste and used sharps et cetera use Polyethylene Coated (PE Coated) and chlorinated polyethylene (CPE) personal protective equipment.

Protective coveralls today from 3M, Dupont, Honeywell, Ansell, and others are either made of new materials like Spunbond Meltblown Spunbond (SMS) or the Spunbond Meltblown Meltblown Spunbond SMMS. The SMS coverall consists of three layers – a top layer, which consists of Spunbond Polypropylene (PP), a middle layer, which consists of Meltblown PP, and a final bottom layer which consists of Spunbond PP. These protective coveralls are lightweight, breathable, soft, and well-fitted, offering excellent cover from occupational risks.

IoT Sensors for Safety & Security

Sensors are used to pick up changes in the environment, whether that is heat, pressure, light, moisture, motion, image, radiation, proximity, position, infrared, photodetector, metals, gas/chemical, force, flame, contact, etc. With industry 4.0, AI, and IoT proliferation, workspaces and industries use smart sensors to increase employee/surroundings safety in many ways.

Smart sensors are edge devices that can process information in real time, leading to quick warning systems and swift decisions. Researchers are discovering how soft and virtual sensors, in combination with physical sensors, 3D camera sensors, and connected surveillance cameras, can elevate workplace security and safety to the next level.

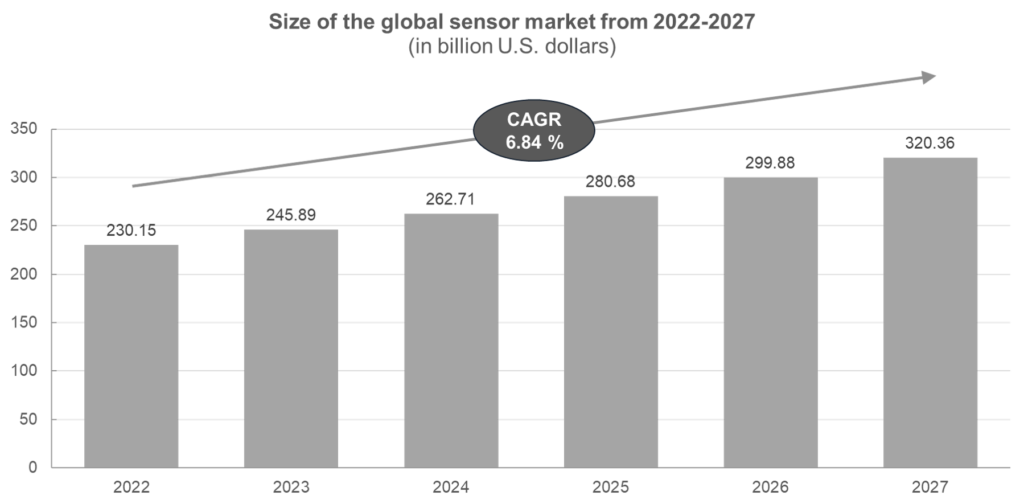

Stellarix performed market research on the IoT valuation and found that the global sensor market is projected to reach USD 320.36 billion by 2027, with a 6.84% CAGR.

Figure: Global Sensor Market Size

Wearable Tech in the Workplace

VerveMotion has developed a wearable robotic device named SafeLift Suit. Wearers need to put on this light-powered exosuit like a backpack. The suit offers up to 240 Newtons of lift force assistance, taking 40% of the strain off the worker with every lift. It has advanced movement analytics and an intuitive control system for customizing workers’ activities. The solution reduces injury rates and leads to a better worker experience.

SolusGuard has built a wearable panic button for off-site staffers working at isolated places. Lone workers don’t need to access their phones or open an app to alert their supervisors in emergencies with this wearable panic button.

Robots, Cobots, and Autonomous Mobile Robots

Robots are present in a wide range of industries. These include agronomics, hospital services, building & construction, space, military, manufacturing, supply chain, and drone delivery. Autonomous mobile robots (AMR) are programmable robots. They also possess a higher level of autonomy, allowing them to perform tasks and navigate their surroundings with greater independence. They have advanced sensors and computer vision. The ARM robot can assist in automating material handling such as heavy machinery and chemicals, support site crew in managing risky daily activities, and reduce workers’ pressure.

Intelligent robots are utilized in areas where robots make agile decisions and inspections using AI and ML technologies. Massive datasets train these robots. Industries widely employ these robots to free site workers from repetitive tasks in almost every aspect. They are used in healthcare in difficult-to-reach/ high-precision robotic surgeries and laboratory work. In addition, the automobile, retail, and food processing industries also utilize robots.

Humans task cobots to perform jobs alongside them, creating a collaborative force between man and robots. Robots take on another pathfinder role in agriculture, reducing human contact during weeding, spraying, and transporting tasks. Robots, humans, and industries are an excellent trilogy, so much so that robot expansion will reach US$43.32bn by 2027.

Industrial Future Safety: Workplace Gensuite for EHS Compliance

Maintaining Environment, health, and safety (EHS) are critical parameters for all workplaces. This is even more so now with a possible update of OSHA’s Hazard communication standard (HCS) soon requiring employers to use proper labeling for indicative chemical flammability, corrosivity, and other such environmental hazards.

This will give staffers a ‘right to know’ about the level of hazardous chemicals they are working with and possibly enhance protection expectations. With advanced AI technology, Benchmark Gensuite uses workflow-integrated computer vision technology to analyze live-streaming videos and photos. The software then integrates the collected data to generate real-time reports and alerts, creating an ultra-safe environment. The system alerts employees if they fail to wear their PPE suits. Additionally, it sends alerts regarding risks from moving objects and aggregates all potential hazards for future insights and analytics. Without question, Benchmark Gensuite, the new EHS tech, can prove to be a game changer for increased workplace safety.

In Summary

In the business scenario, organizations and workplaces actively measure their level of safety and security. To thrive in the long haul, businesses must earn the trust of employees and stakeholders by incorporating best EHS practices. These practices should promote workers’ safety and health in a scientific and well-charted manner. PPE coveralls, made of new-age materials, have emerged as a top industry requirement. They are crucial for protecting on-site workers from known risks and occupational dangers. Moreover, customization of PPE coveralls based on work criticality further enhances worker protection. Also, State-of-the-art industry 5.0 tools, comprising top IoT, advanced robots, and AI tech created by foremost companies, actively mitigate injuries, accidents, and any potential work failures.