Giga Casting 2.0: Transforming Automotive Manufacturing

Technological advancements and the need for sustainability and efficiency in the manufacturing industry lately are forcing component manufacturers, especially in the aerospace and automotive industries, to undergo a seismic shift. Giga casting has erupted as a disruptive innovation designated to be pioneered by Fiorenzi Dioni and Richard Oberele from the Italian die-casting machine manufacturer Idra. Tesla has furthered the revolution by trailblazing giga casting 2.0., aiming to transform the automotive space, precisely impacting and transforming the making of electric vehicles in the future.

Know About Giga Casting

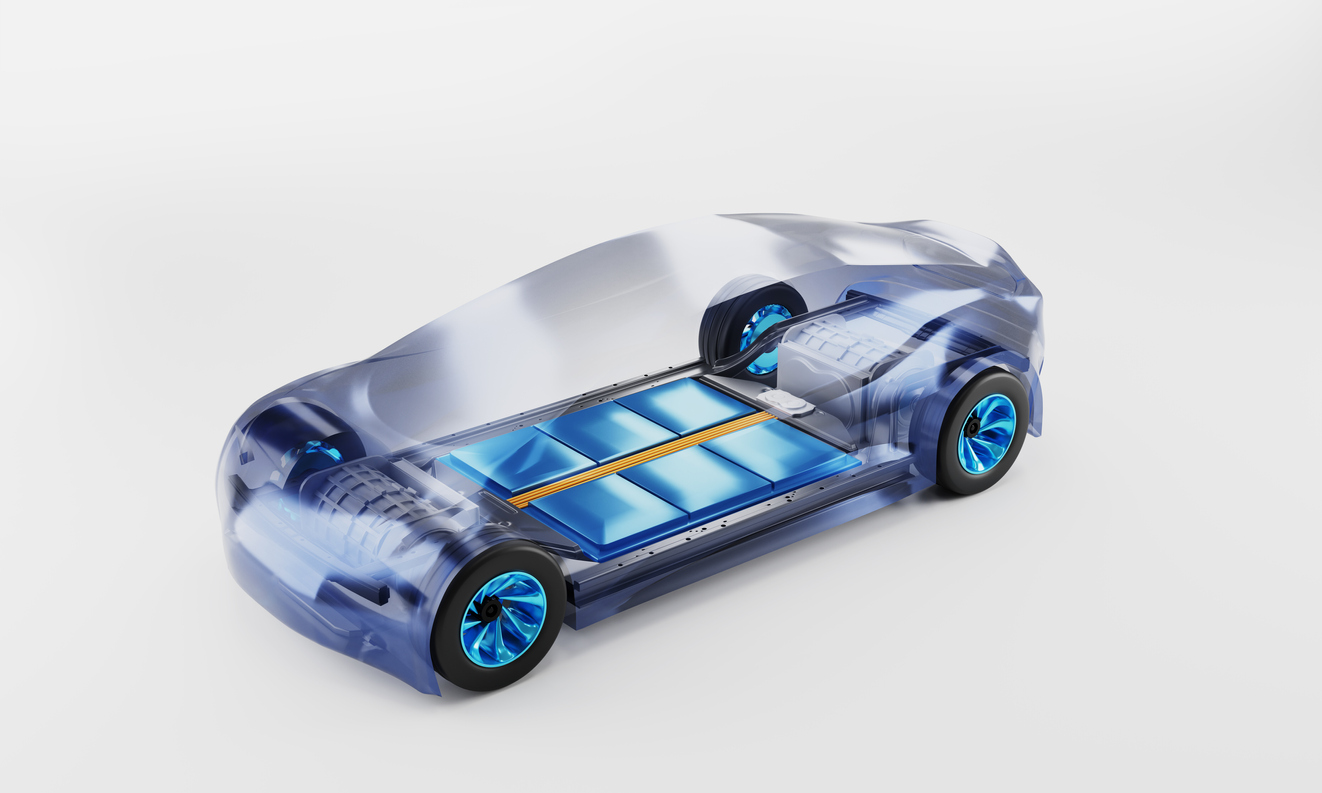

Giga Casting is a method for creating large and complex automotive components using high-pressure die-casting in a single piece. It diminishes the requirement for assembling various individual parts in a vehicle and hence saves time, effort, and resources. At the same time, the traditional process needs hundreds of components, along with bolting and welding, to stitch multiple parts, while giga casting untangles it through large-section casting like the underbody.

What is Giga Casting 2.0?

Giga casting 2.0 is defined as the avant-garde in the automotive industry that has expedited the manufacturing process. The concept of giga casting 2.0 was originally built upon giga casting, which includes humongous aluminum die-casting machines to manufacture single-piece colossal structures for various vehicle parts. Thus, it minimizes the use of several components and significantly reduces the assembling steps for manufacturers.

The comprehensive technology comprises evolution in production efficiency, quick cycle times, and enhanced material properties, creating vehicles that are solid-built, lightweight, and cost-effective. Giga casting 2.0 aims to push the idea of sustainability, streamline production, and improve scalability precisely for EV companies.

Giga Casting: Evolution to 2.0

Phase Giga Casting 1.0

The evolution of giga casting into 2.0 began with Tesla’s maiden iteration, which can also be marked as giga casting 1.0. It primarily aimed at building rear and front structures for its model Y. This advanced technology helped Tesla reduce its production costs while increasing its production. Gigantic machines were used to exert clamping pressures ranging from 6000 to 9000 tonnes, stamping the mark of initial success.

Advancements in Giga Casting 2.0

Tesla aims to raise the bar even higher with giga casting 2.0, finding the possibility of casting all EV components in one piece. Interestingly, this practice can reduce the number of parts from about 400 to just a few or one, thus altering the fundamental sense of vehicle manufacturing and design.

a. Advanced Materials

Giga casting 2.0 has introduced the usage of improved and new materials, like aluminum, for robust strength and lightweight properties. Such materials contribute to the vehicle’s overall weight reduction, improving the cast components’ strength and durability. This is vital for the aerospace and automotive industries and directly translates to fuel efficiency and better performance.

b. Increased Precision

Giga casting 2.0 offers stupendous precision when manufacturing vehicles. Manufacturers have been empowered with enhanced AI-driven controls, die-casting machines, and improved cutting-edge sensors. Thus, the tolerance power of components has notched higher, enabling fewer to no defects. These features can lead to higher-quality products and less post-production work, such as machining or finishing.

c. Sustainability

Sustainable production is pivotal for any industry today, and giga casting 2.0’s main focus remains environmental sustainability. This technique emphasizes low or no carbon emissions, resource efficiency, reduced material waste, and low energy consumption. Production volumes can be escalated through casting process optimization with a low GHG footprint.

d. Multi-Industry Applications

Giga casting 2.0 technology can soon find broader applications in various industries, like construction, robotics, renewable energy, and aerospace. This advanced version of casting technology is more adaptable, permitting manufacturers to produce large and complex components for a lot of sectors.

Advantages of Giga Casting 2.0

Giga casting is quickly expanding its wings in the automotive manufacturing industry due to its numerous advantages in terms of swift and hassle-free process. Some of the advantages are:

- Component Count Reduced: One of the major advantages of giga casting 2.0 is that it reduces the number of components needed for assembling vehicles. Interestingly, several parts are integrated into a single casting, significantly streamlining the process and saving resources. Tesla successfully implemented this technique in Model Y, which replaced 171 parts and required only two large castings, diminishing the complexity and failure chances associated with numerous seams and joints.

- Optimized Manufacturing Performance: The giga press technology accentuates the production of large components and massively reduces turnaround time. Moreover, it also significantly minimizes labor costs while expediting the production cycle, enabling new models to be built within 18-24 months instead of 48 months. Notably, the ability to process up to 45 castings an hour speaks volumes about efficiency.

- Enhanced Structural Integrity: When huge components are assembled into one large component in casting, the structural integrity witnesses remarkable automotive integrity. Fragile points, which may happen during the welding of different parts, are eliminated through seamless designs. Thus, the final product is more robust and reliable.

- Potential for Future Innovations: With the advent of giga casting 2.0 on a massive scale, avenues for bigger innovations have opened for vehicle manufacturers globally in terms of designing and manufacturing.

Challenges with Giga Casting 2.0

Giga Casting 2.0 has undeniable and unbelievable potential, promising the industrial world with unthinkable impact. However, it has its share of following challenges:

High Risks: The creation of high molds can be a risky affair, with adjustment costs as high as millions of dollars. Thus, developing it requires huge investments. There’s a term called the giga cast dilemma, which refers to the balance between financial risks and efficiency gains associated with larger molds during their development. Recently, Tesla paused its one-piece casting process following manufacturing issues and costly delays in the development of the Model 2.

High Production Capacity: For the proper functioning of giga casting 2.0, manufacturers may need massive gigapresses that can exert clamping forces beyond 16,000 tonnes, which is enormous compared to the current capacities. However, this may not be feasible for every vehicle manufacturer globally. Also, it demands a larger factory space and the latest machinery designed to perform specific manufacturing tasks.

Technical Hurdles: Several technical issues cast a shadow of doubt on ensuring high-quality consistency and performance in all massive components. Moreover, reaching that standard requires significant advancements in manufacturing processes and materials science.

Giga Casting 2.0 Future

As the technology continues to develop and grow, so does the impact and importance of giga casting 2.0 on the manufacturing landscape. Here are the future trends that may excel:

1. Integration with 3D Printing

Integrating giga casting 2.0 with 3D printing technology is possible, revolutionizing the creation of large and complex components. Hybrid manufacturing processes that merge the speed and efficiency of Giga Casting with the design flexibility of 3D printing are set to unlock new opportunities for producing lightweight, highly customized components.

2. Advanced Automation

As AI and machine learning are integrated into various industries, automation will surge in importance to optimize the casting process to the next level. Downtime will be reduced significantly, while efficiency will improve through real-time adjustments in machine production and predictive maintenance.

3. Global Expansion

The global adaptation and expansion of giga casting 2.0 in other industries and by several manufacturers are on the radar, as the technology is accessible in the open. As it becomes cost-effective with time, several small and medium enterprises will be able to afford it and utilize that in their production lines while enhancing productivity, quality, and volumes.

Conclusion

Giga casting 2.0 is the foundation of future innovation spanning almost every industry worldwide. It offers unspeakable advantages, including sustainability, time savings, effectiveness, and cost reduction. The production of humongous components from various and complex small ones will reshape the potential of various industries, such as renewable energy, construction, aerospace, and automotive. It will infuse immense potential in companies to alter the industrial landscape for the better in the interest of their growth.