In today’s rapidly evolving world, the mining industry is under increasing pressure to improve operational efficiency while reducing environmental impact. Enter retrofitting: a game-changing solution that is revolutionizing mining operations. By upgrading existing vehicles with advanced technologies and innovative features, miners can enhance productivity, safety, and sustainability without the need for costly new equipment. Why invest in retrofitting mining vehicles? Well, it offers significant advantages. First and foremost, it allows mining companies to optimize their existing fleet, maximizing the return on their initial investment.

By retrofitting older vehicles with state-of-the-art components, miners can bring them up to modern standards, improving performance and reducing maintenance costs. Plus, retrofitting enables mining operations to meet stringent environmental regulations and make significant strides towards sustainability goals. By adding emission reduction technologies, fuel-saving systems, and noise reduction measures, mining companies can minimize their carbon footprint while enhancing their public image.

In this document, we will explore the power of retrofitting in the mining industry, delving into the various benefits and innovative solutions available. So, join us as we discover how retrofitting mining vehicles is transforming the industry, one upgrade at a time.

Retrofitting diesel-powered mining machinery with a battery-electric solution is becoming increasingly popular as industries strive to reduce emissions and improve operational efficiency.

According to Stellarix Research, the electrification in the mining market can grow from 1.2 US$ billion in 2020 to 11.7 US$ billion in 2030 at a CAGR of 19.60%. Moreover, the autonomous mining vehicle market may grow from 2.7 US$ billion in 2020 to 5.2 US$ billion in 2027 at a CAGR of 9.80%.

Vital Findings

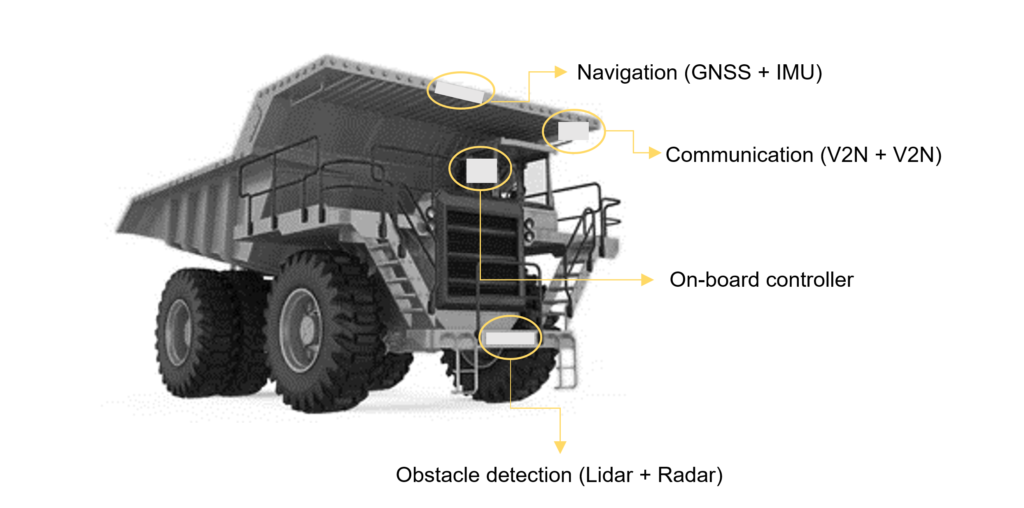

- SafeAI retrofits heavy vehicles and site operations with self-driving technology to improve productivity and safety in the work environment. Also, they have successfully overcome the challenges in the retrofitting process, including installation, irregular disturbances, and intractability

- Anglo American nuGenTM is the first sizeable ultra-class mining haul truckpowered by hydrogen. It combines a hybrid hydrogen fuel cell with a battery which allows energy recovery during braking

- ABB’s diesel to electric conversion solutions helps in customization, upgrading electrical. infrastructure, robust enclosure and reducing carbon footprint. It solves the common challenges in the retrofitting process such as vibration & harsh environment, power demand and integration complexity.

- ABB is one of the leading manufacturers of electric drives and motors, designed for the electrification of mining vehicles. These electrification retrofit solutions also aim to provide a transition toward sustainable mining.

Key Technologies

- Honeywell provides high-precision inertial navigation technology, used for accurate positioning, navigation, and orientation by incorporating a Kalman-filter-based fusion algorithm

- iXblue provides compact inertial measurement units with FOG (Fiber-Optic Gyroscopes) and VBA (Vibrating Beam Accelerometers) technology. Moreover, they are used in the sensor core to provide rotation and acceleration vectors

- ABB’s eMineTM grid-to-wheel technology which involves retrofitted pantograph in trolley-assisted haulage. ABB and Hitachi have collaborated to integrate trolley-assisted systems and overhead lines in order to reduce CO2 emissions in mines

Key Innovations

- Caterpillar innovated a retrofittable remote control system that enables heavy vehicles to be controlled remotely, thereby enhancing operator safety (US2022026899A1)

- Fujian Hongshidai proposes a high-power traction motor direct drive system designed for use in 100-ton electric mining dump trucks. This system is intended to reduce energy loss, eliminate the need for maintenance, and ensure consistent linear power delivery (CN114537242A)

Report Coverage:

- Overview of retrofitting in mining vehicles

- Retrofitting for autonomous operations

- Process Flow

- Market Overview

- Market Trends

- Key Solution Providers

- Commercialized Solutions

- Patented Innovations

- Technology Matrix for Key Competitors vs Solution

- Key Player Profiling

- SafeAi

- Wenco

- Retrofitting for electrification

- Process Flow

- Market Overview

- Market Trends

- Key Solution Providers

- Commercialized Solutions

- Patented Innovations

- Technology Matrix for Key Competitors vs Solution

- Key Player Profiling

- ABB

- Flanders

- Future perspective and Stellarix recommendations

How to Get Your Copy: To access this invaluable document and gain a competitive edge in your industry, simply reach out to us. We’re excited to share our expertise and insights with you. To get your copy, please contact us via the contact us, or feel free to send us an email at sales@stellarix.com.