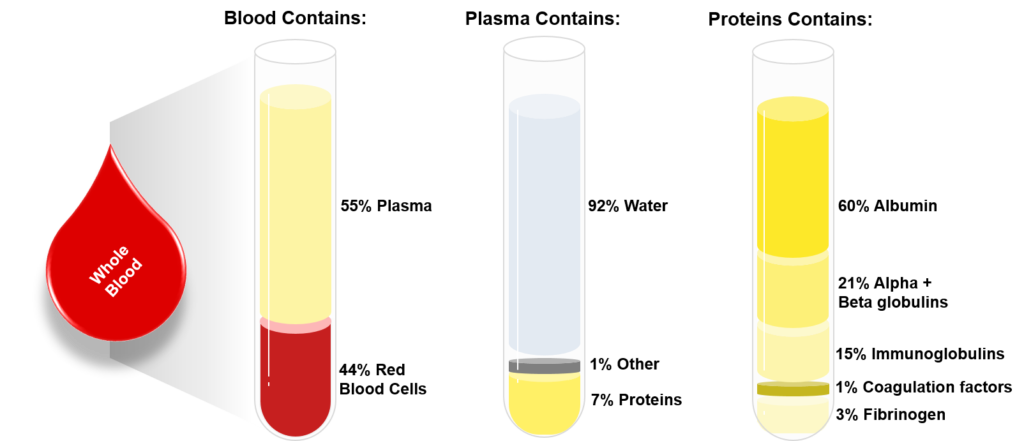

The human body is a complex marvel of biological systems that offer incredible potential for therapeutic discovery. Plasma, the liquid part of blood, is a rich source of essential proteins and other components with remarkable therapeutic properties. To create plasma-derived therapeutics, the process begins with the collection of plasma from volunteer donors who undergo extensive screening for infectious diseases to ensure the safety and purity of the plasma. The collected plasma is then carefully processed to remove any impurities or pathogens, resulting in highly pure plasma used to produce various medical products. These plasma-derived therapeutics can be used to treat a broad range of medical conditions, offering hope and healing to countless people in need.

What is Plasma Fractionation and What are the Methodologies Involved?

Plasma fractionation, in the simplest of terms, is a medical procedure that involves separating different components of blood plasma. The ultimate objective of plasma fractionation is breaking down blood plasma into its components, i.e., plasma proteins so that they can be injected or administered to patients depending on their medical condition.

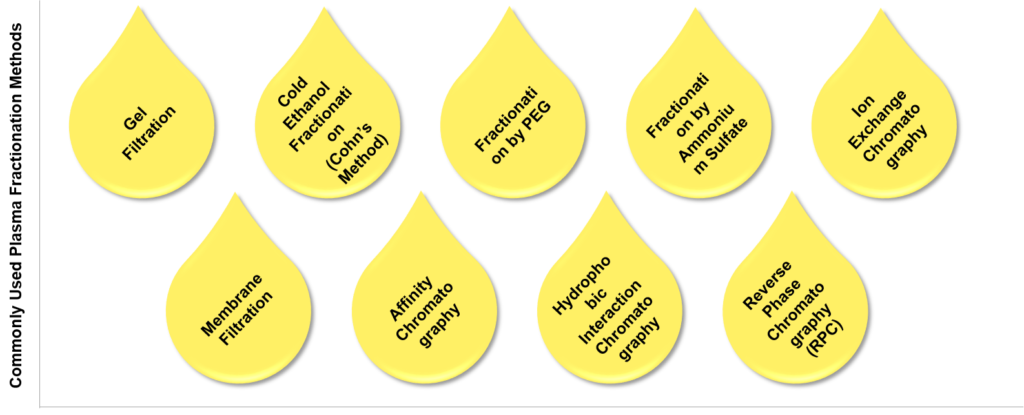

Above mentioned are a few of the most commonly used plasma fractionation methods/technologies. However, equipment capital costs, facility footprint (how much space the equipment will occupy within the facility), complexity of the process, number of cycles, and reasonable cycle time are some of the drawbacks of conventionally used methods.

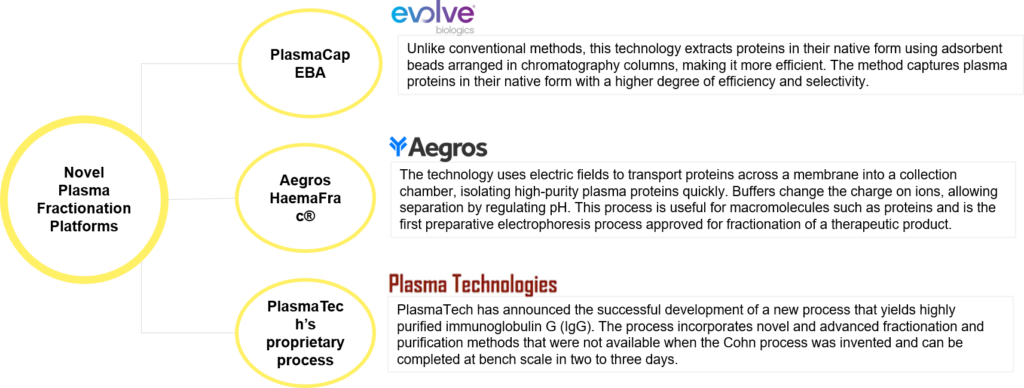

A few novel plasma fractionation platforms are being developed that are overcoming the drawbacks of commonly used methods along with improving yield and purity of plasma components.

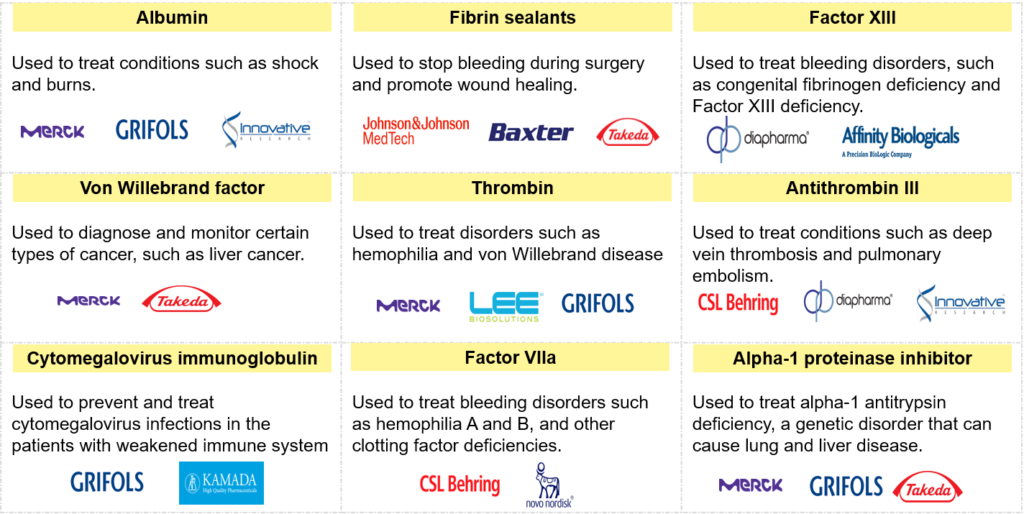

Plasma-derived therapeutics: A Spectrum of Therapeutic Solutions

Plasma derived therapeutics encompass a diverse range of therapies targeting a multitude of rare and chronic diseases.

Challenges & Future Perspective

Plasma-derived therapeutics are a type of medical product that has several advantages over other products. However, there are also some risks associated with their use.

One of the risks is the possibility of transmitting infectious diseases like HIV and hepatitis since these products are made from human plasma. Additionally, allergic reactions can occur and range from mild to severe, including symptoms such as itching, hives, and difficulty breathing. Patients are usually monitored closely after receiving plasma-derived therapeutics to minimize this risk.

Another challenge is the shortage of plasma supply. Despite the steady increase in plasma supply, it is not enough to meet the product demand, especially for Ig therapies. Plasma collection for fractionation is a complex process that requires a national regulatory body to oversee the regulatory and safety compliance of its collection centers and logistics providers. Plasma fractionation facilities are also complex and expensive to design and build, requiring large and qualified labor. Despite these challenges, plasma-derived therapeutics are an essential part of modern medicine. They have saved countless lives and improved the quality of life for millions of people worldwide. Their versatility is one of their most significant benefits as they can treat a wide range of medical conditions, including immune system disorders, bleeding disorders, and liver disease. They are easily stored and transported, making them ideal for emergencies.

Novel technologies are emerging in plasma-derived therapeutics, like flammable material-free fractionation, continuous manufacturing, and automation, which will likely appear in future plasma fractionation and purification facilities. Subcutaneous Ig SCIG use is expected to continue to grow at a faster rate than IVIG, and manufacturers are starting to ramp up their SCIG production.