All matter is chemical, and all energy comes from what we call stuff. Chemical engineering involves working with raw materials and transforming them into valuable products. Chemical engineers use their knowledge of various sciences and convert lab outcomes into commercial projects. The world consumed over 218,312 TWh of energy in 2022, of which coal/oil/natural gas comprised 97,824 TWh.

Renewable energy was 30,551 TWh, mainly attributed to Sweden, France, the United States, and Canada. Today, renewable energy has found new avenues in electrolysis, photocatalysis, and fusion reactions. The International Energy Organisation (IEA) team states that the world has to triple its renewable energy capacity and significantly reduce emissions from now to 2030. Also, they develop modular nuclear reactors, increase global solar power energy and wind energy, and manufacture high-performing electric vehicles and low-emission chemicals like hydrogen and ammonia for power.

Renewable Energy: Is Green Hydrogen the Next Generation Fuel?

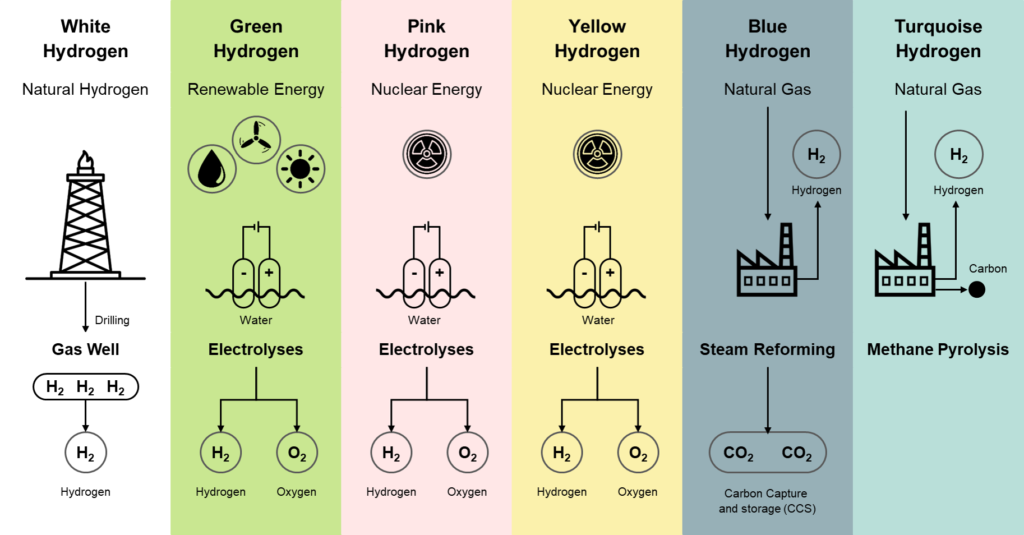

H2 is seen as the future fuel that will power cars, trucks, airplanes, long-haul transport vehicles, and high-temperature heat-reliant steel/cement/fertilizer industries. Different methods harness hydrogen and have been named green, blue, brown, yellow, pink, white, and turquoise hydrogen.

- Derived from one of the most abundant elements, H₂O, green hydrogen stands out as the most pro-environment option

- Producers create blue hydrogen by using natural gas in the presence of a catalyst through steam methane reforming (SMR). Subsequently, they employ a carbon capture utilization and storage (CCUS) process to capture the resulting carbon, enhancing the environmental friendliness of this hydrogen variant.

- Using solar power electrolysis, scientists produce yellow hydrogen, which is a relatively new advancement

- Gasification converts coal into brown hydrogen, rendering it environmentally hazardous when released into the atmosphere.

- An electrolysis process utilizes nuclear energy to power pink hydrogen

- White hydrogen production uses fracking, and mostly the process is energy-intensive, requiring heavy machines, chemicals/fossil fuels

- Turquoise hydrogen uses methane pyrolysis to produce hydrogen, a relatively new process. When capturing the carbon, it transforms into a pro-climate element.

Figure 1: Elucidating different Hydrogen sources

Top Renewable Energy Companies

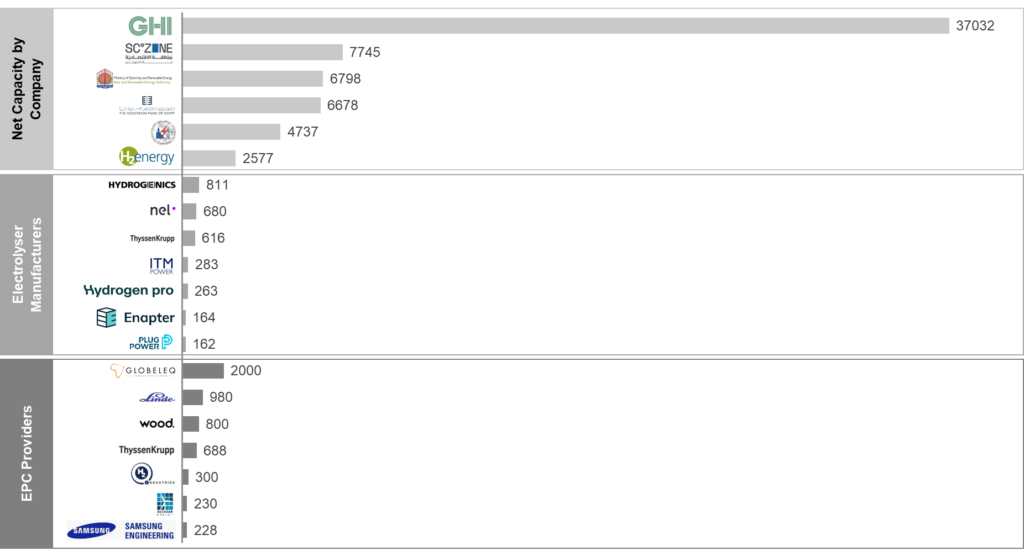

Top world green net capacity hydrogen manufacturing companies, electrolyzer manufacturers, and EPC providers are GHI, H2 Green Energy, Suez Canal Economic Zone (SCZONE), ITM Power, Hydrogen Pro, Enapter, John Wood Group, Neom Green Hydrogen Company (NGHC), Air Products, First Hydrogen, AMEA Power, Lhyfe, Linde, Siemens, BP, Plug Power, ThyssenKrupp, Alcazar Energy. The total green hydrogen pipeline capacity was 166 metric tonnes in 2022.

Figure 2: Green Hydrogen Leaders – Q4 2022 | All values are in kilo tons per year)

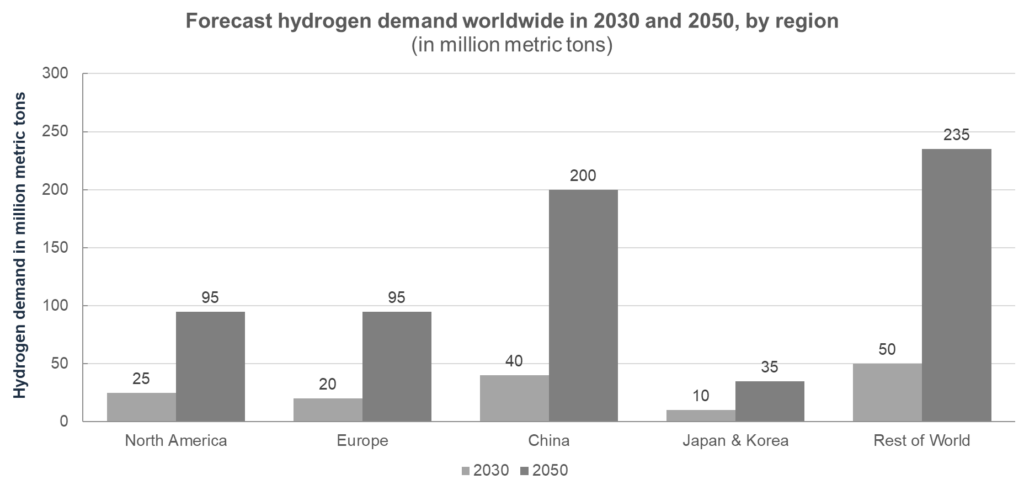

Hydrogen is the most abundantly available element. Atomic number 1 shows a global demand forecast of 145 million metric tons in 2030 and 660 metric tons in 2050. Europe and North America’s hydrogen market shows a fivefold growth from 2030 to 2050.

Figure 3: Hydrogen demand

Material Scientist Exploring Catalysis Of Light

Over the last few decades, research has been done on photocatalysis to produce hydrogen. Researchers are actively conducting laboratory work to determine how to transform it into a viable process for industrial application. Photocatalysis uses light to create chemical reactions and thus develop hydrogen. Also, experiments by the Syzygy Plasmonics team are ongoing to see how ammonia and light (LED, too) can be used to create ‘antenna-reactor’ plasmonic photocatalysts to create the lightest gas on earth. Furthermore, other elements that are showing promise are metal oxides and visible light active (VLA) for water-splitting reactions. Moreover, photocatalysis is an entirely sustainable way to split water and achieve other responses, proving to be one of the key drivers in a sustainable and circular economy.

Linking Battery Chemistry With Recycling

Everything today we need comes with batteries. Different kinds of batteries are in use, namely lithium iron phosphate battery (LFP), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), nickel manganese cobalt oxide (NMC), Lithium titanate (LTO) and Lithium nickel cobalt aluminum oxide (NCA) and Mckinsey projects that Li-ion battery revenue value chain will reach over $400 billion by 2030.

As batteries use various metals and minerals like Lithium (Li), Cobalt (Co), Nickel (Ni), Aluminium (Al), Manganese (Mn), Vanadium (V), and Lead (Pb), the current intent is to recycle these elements than getting them from primary raw material sources. The adoption of thoroughly tested battery recycling techniques is necessary to establish effective recycling capabilities. This includes implementing government intervention, ensuring producer responsibility, and developing a comprehensive understanding of the end-of-life cycle of batteries.

Renewable Energy: Hydrogen Fuel Cells Changing Mobility

Researchers are considering hydrogen fuel cells for long-haul journeys involving class 8 trucks. In drivetrain technology, these fuel cells surpass electric cells in performance, as they enable refueling of a 100 KG hydrogen tank 15 times faster and eliminate the need for frequent stops. Daimler is the company that is developing this technology. Unlike electric batteries, hydrogen fuel cell makes their own electricity on board.

Renault’s hydrogen vehicle uses pressurized hydrogen fuel cell power and a lithium-ion battery to run its car. The fuel cell works on an electrochemical reaction called oxidation-reduction (redox), which converts hydrogen into electricity. Moreover, the major manufacturers in the hydrogen fuel cell market are FuelCell Energy Inc, Bloom Energy, Hydrogenics Corporation, Ballard Power Systems, SFC Energy AG, Nedstack Fuel Cell Technology B.V., Doosan Fuel Cell America, Inc., and a few more.

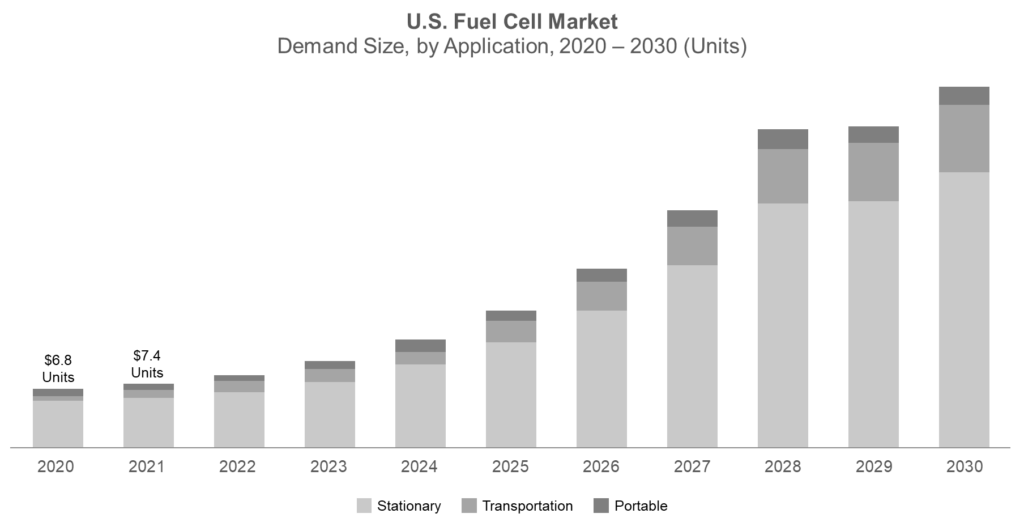

The fuel cell market is slated to grow at 19.9 CAGR and be worth $26.1 Billion by 2030, according to Grand View Research Inc. Stationary fuel cells dominated the market in 2022 with a 69.0% share. In addition, the transportation vertical of the fuel cell market is also gaining much traction, and so are the portable fuel cells for usage in laptops, mobiles, and personal electronics.

Chemical engineers are catalyzers, and they study the physical world at its atomic level. They lead the development of new substances, create large-scale industrial processes, and design & manage optimal production at chemical plants and industries.

They develop process safety at plants/reactors and decide the best storage of renewable fuels and safe/economical transportation. Chemical engineers in the environmental/renewable sector use their know-how to utilize amply available organic and inorganic compounds to develop new materials/fuels. They also capture the harmful GHG and develop various processes to accomplish the broad net zero emission goals.

Sustainable Nuclear Fusion Tech To Produce Helium

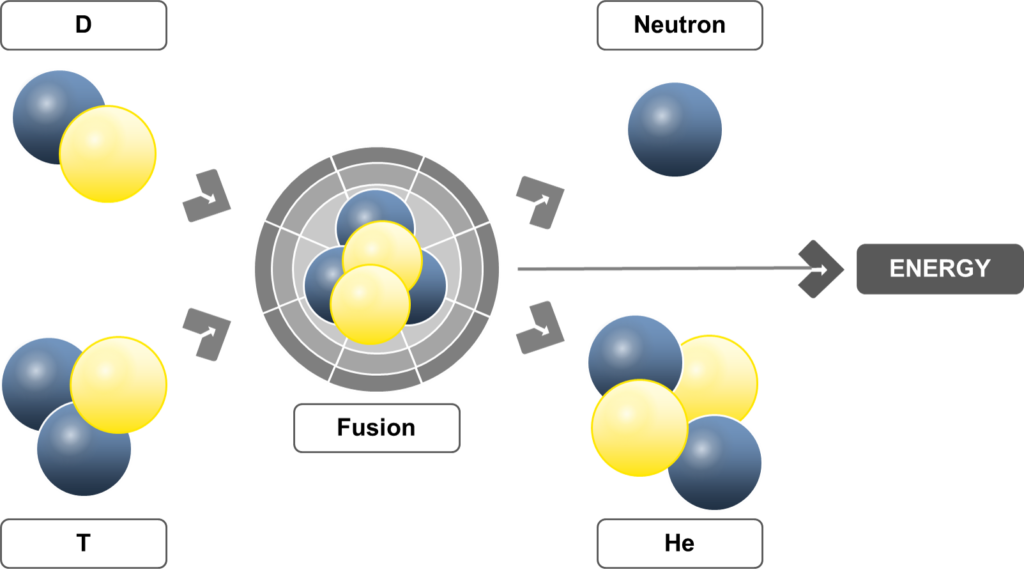

With the earth’s population turning 8.6 billion by 2030, stable energy generation is key to our future security and cohesion. Also, the second most abundant element in the universe is helium. Helion Energy is building a fusion reactor to generate electricity through the isotope deuterium.

Deuterated water (HDO) occurs in normal water. It’s available in copious amounts in our earth’s oceans, as every atom has a nucleus with electrons, protons, and neutrons.

Figure 4: Nuclear Fusion at the atomic level

Heating leads to the loss of electrons from positively charged neutrons, forming a hot cloud known as plasma. Moreover, scientists and researchers term the process of combining two light nuclei into a single, heavier element as nuclear fusion. Helion is producing electricity directly from the charged plasma itself without the need to use energy to turn steel turbines. Additionally, chemical engineers are the ones who are managing this pioneering nuclear fusion technology production on a large scale.

The global helium market is valued at $1911.28 Million in 2022 and shows a CAGR of 5.31% between 2023 and 2029. The key players in helium production are Exxon, Gazprom, Qatargas, Linde, PGNiG, and Air Liquide. Helion is backed by artificial intelligence (AI) company ChatGPT and also Microsoft has already brought its yet-to-be-produced electricity. Clean energy has become the focus for top IT leaders and companies today. So far, the current global energy investment in clean energy has been $1740 billion compared to fossil fuels which saw an investment of $1050 Billion. Moreover, IEA has asserted that the clean energy investment needs to hit $4 Trillion by 2030 to meet the Net Zero emission target by 2050.

Figure 5: Current global energy investment in clean energy

Conclusion

Chemical engineers like Michael Faraday first discovered electrolysis in 1834. The Scottish chemist Sir William Ramsay found the noble gas helium in 1895. Chemical engineering has always paved the way for future energy transformation and seismic industrial shifts. Renewable energy is humanity’s most significant and rare chance at restoring Earth’s atmospheric temperatures. Subsequently, green hydrogen, helium, ammonia, Ilios, wind, modern biomass, MSW, and potential future clean energy sources generate electricity. Another advanced material company, Carbon Rivers, in collaboration with the U.S. Department of Energy, has cracked how to recycle decommissioned wind blades into useful glass material.

The current and future energy outlook is pro-clean fuels, clean energies, clean agriculture, and clean chemistry. Hydrogen fuel for off-road vehicles, commercial energy production from helium likely by 2028, and the adoption of AI would bring much-needed accountability in the energy sector. Moreover, chemical engineers are the epicenter of all the current innovations in clean energy transition. Also, they are responsible for converting novel clean technologies to industrial-scale manufacturing. Additionally, Standardization, public and private partnerships, inter-country collaborations, and renewable energy value chains will improve clean energy production.