Sodium-ion batteries (SIBs) are energy conversion and storage devices that employ sodium ions to transfer positive charge between the anode and cathode. This process enables the conversion of electrical energy into chemical energy and vice versa. One widely recognized example of devices similar to SIBs is the popular lithium-ion batteries (LIBs).

Sodium-ion batteries offer several advantages over other battery technologies. In contrast to lithium-ion batteries, sodium-ion batteries are relatively more affordable, possess a slightly lower energy density, exhibit enhanced safety features, and demonstrate similar power delivery characteristics. Let us explore in depth the technological and commercial prospects of sodium-ion batteries.

What is a Sodium-Ion Battery?

A sodium-ion battery is rechargeable, similar to the widely used lithium-ion battery. However, it employs sodium ions (Na+) as the charge carriers instead of lithium ions (Li+). A sodium-ion battery’s operational principles and cell structure closely resemble those of lithium-ion batteries, with the distinction being using sodium compounds instead of lithium compounds.

Working of Sodium-ion Batteries:

- During charging, sodium ions are extracted from the cathode material, resulting in its deintercalation. Conversely, during discharge, sodium ions are reinserted into the cathode material.

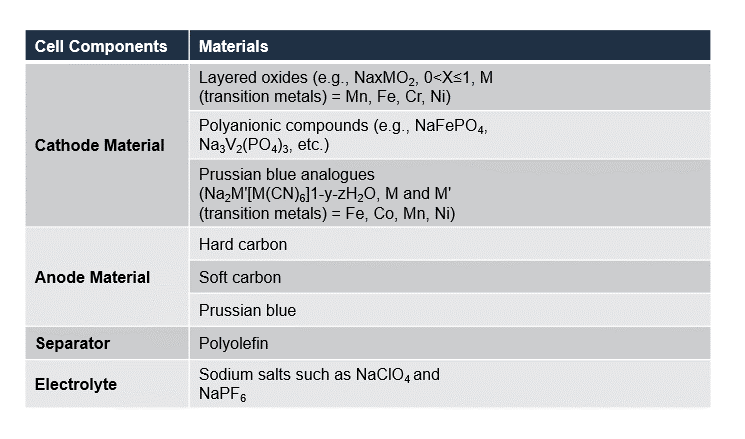

- Common cathode materials for Na-ion batteries include transition metal oxides, phosphates, or polyanionic compounds. In contrast, carbon-based materials, such as hard carbon or metal alloys like tin or antimony, are used for the anode.

- The electrolyte typically consists of a sodium salt dissolved in an organic solvent or a solid-state electrolyte. The choice of electrolyte depends on factors such as ionic conductivity, stability, and safety.

- A separator is used to physically separate the cathode and anode while allowing the passage of sodium ions. It prevents short circuits and direct contact between the cathode and anode, possibly leading to the battery’s failure.

The overall operation of a sodium-ion battery involves the reversible intercalation and de-intercalation of sodium ions in the cathode and anode, respectively, while maintaining the flow of electrons through the external circuit. This cyclic process allows for the storage and release of electrical energy in sodium-ion batteries.

Advantages

- Abundance of Sodium: Sodium is abundant and widely available in the Earth’s crust, making it a cost-effective and sustainable choice for battery production. It is more abundant than lithium, reducing resource availability and price volatility concerns.

- Safety: Lower reactivity and reduced risk of thermal runaway make sodium-ion batteries a safer alternative to lithium-ion batteries. Using sodium ions as charge carriers reduces the likelihood of fire or explosion, enhancing the overall safety of the battery technology.

- Similar Chemistry: SIBs share similar working principles and cell construction with lithium-ion batteries. This similarity allows for the adaptation of existing lithium-ion battery technologies and infrastructure to SIBs, making integration and scaling up production easier.

- Compatibility: SIBs can be used as a drop-in replacement for lithium-ion batteries in many applications. They can fit within existing battery compartments and systems, enabling seamless integration into various devices, electric vehicles, and energy storage systems.

- High Energy Density: Sodium-ion batteries have the potential to achieve high energy densities, allowing for longer-lasting and more powerful energy storage. This characteristic is crucial for applications requiring high energy storage capacity, such as electric vehicles and renewable energy storage.

- Long Cycle Life: Sodium-ion batteries can exhibit a long cycle life, meaning they can endure many charge and discharge cycles without significant degradation. This longevity contributes to the overall lifespan and reliability of the battery, reducing the need for frequent replacements.

- Environmental Friendliness: SIBs are considered more environmentally friendly than other battery technologies. Sodium is abundant and easily recyclable, reducing the environmental impact associated with resource extraction and disposal of batteries.

- Temperature Tolerance: SIBs can operate efficiently over a wide temperature range. They perform well even in extreme temperatures, making them suitable for applications in diverse climates and environments.

- Scalability: The production of SIBs can be scaled up to meet increasing demand. As the technology matures, advancements in manufacturing processes and economies of scale can potentially reduce costs and make sodium-ion batteries more accessible and affordable.

- Application Versatility: SIBs can be utilized in various applications, such as portable electronics, electric vehicles, renewable energy storage, and grid-level energy storage. Their versatility makes them suitable for multiple industries and facilitates the transition to a more sustainable and energy-efficient future.

Market Potential

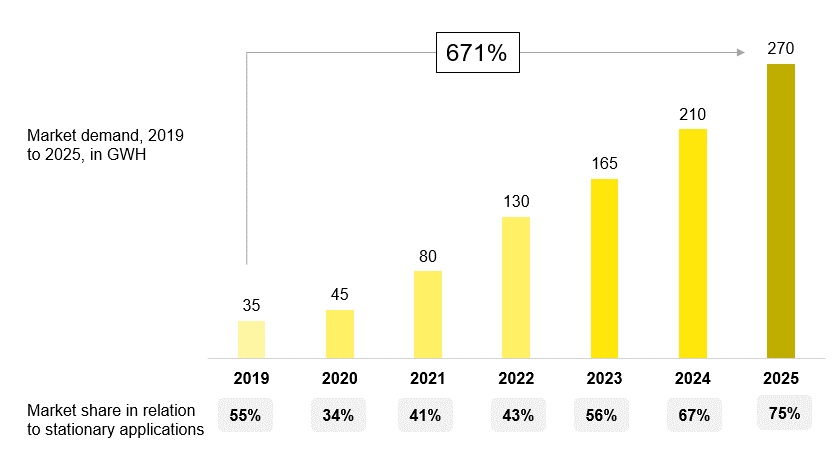

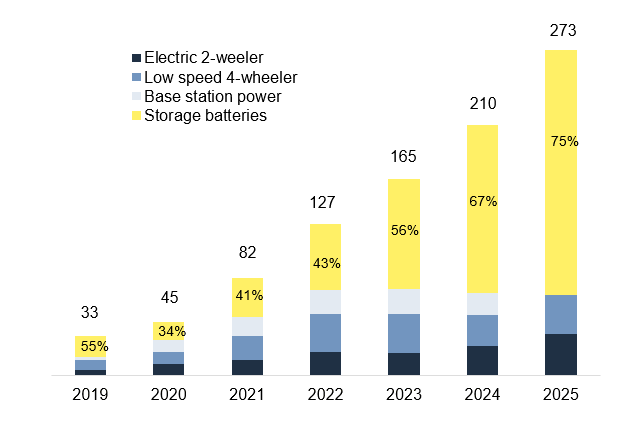

The performance of sodium-based batteries and the anticipated improvements in key indicators, such as energy density, have generated significant interest in this technology.

However, one of the challenges encountered by sodium batteries is the requirement to establish a market for components. Only a limited number of manufacturers, around 2 or 3 suppliers globally, are responsible for processing and preparing this raw material in the appropriate format for the battery industry. E-Lyte, a European company, is one of the key participants engaged in sodium processing within Europe; however, the sourcing primarily relies on Asian markets. Therefore, for the industrialization of this technology in Europe, it becomes imperative to establish additional and improved European partnerships for the production of “Battery Grade” sodium.

Market Activities

- In 2022, Natron, a leading manufacturer of SIBs, collaborated with Clarios to manufacture SIBs at a lower cost by leveraging a portion of the Clarios Meadowbrook lithium-ion facility for sodium-ion manufacturing

- In March 2023, CATL announced the mass production of its Qilin batteries. It introduced an innovative sodium-ion battery technology, the Qilin battery, in 2022.

- In April 2023, Chery made a noteworthy announcement by adopting CATL’s Qilin batteries for its vehicles. Thus, making it the pioneering automaker to utilize CATL’s SIBs in its vehicles.

- In February 2023, HiNa Battery unveiled three new sodium-ion battery cell products. Additionally, they announced a strategic collaboration with Anhui Jianghuai Automobile Group Corp (JAC). HiNa Battery Sehol, a brand formed through a joint venture between JAC and Volkswagen Anhui, has successfully developed a prototype vehicle based on the Sehol E10X model, incorporating SIBs

Potential Applications:

As the world embraces the transition to sustainable energy solutions, sodium-ion batteries are emerging as a promising contender. It is catering both stationary power and electric vehicle applications. These batteries can potentially revolutionize the energy storage landscape with their unique advantages.

SIBs offer a cost-effective alternative to lithium-ion batteries in the stationary power sector, making them suitable for large-scale energy storage systems. For instance, the Chinese battery maker CATL introduced the Qilin battery, which features high energy density and long cycle life and is a game-changer for energy storage.

In the realm of electric vehicles, sodium-ion batteries are gaining attention. They have the potential to enhance range and reduce costs. Chery, a leading automaker, became the first to adopt CATL’s sodium-ion batteries in its vehicles, which showcases the growing confidence in this technology.

These advancements illustrate the immense potential of sodium-ion batteries in addressing energy storage. Also, the electrification needs of both stationary power systems and electric vehicles. With further research and development, SIBs promise to drive sustainable energy solutions and shape the energy industry’s future.

Conclusion

Sodium-ion batteries (SIBs) present numerous advantages for stationary power and electric vehicle applications. They hold tremendous promise due to their cost-effectiveness, enhanced safety, compatibility with existing infrastructure, high energy density, long cycle life, environmental friendliness, temperature tolerance, scalability, and application versatility. As research and development continue, SIBs have the potential to revolutionize the energy storage landscape. Moreover, they can contribute to a sustainable future.