Magnetic Sensor: Enabling High-Quality Sensing Devices

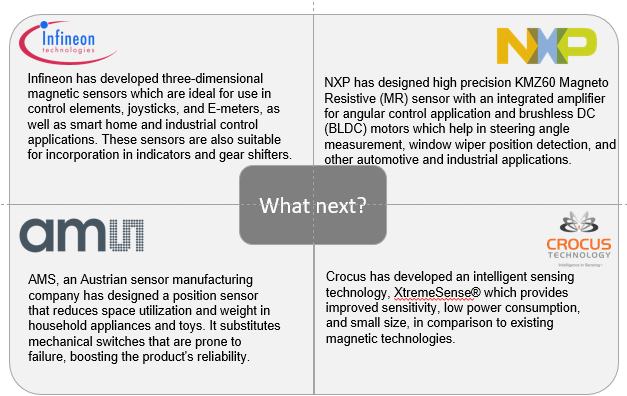

The scope of magnetic sensors is continuously moving beyond industrial and biomedical applications. New use cases and demands, such as IoT, Industry 5.0, flexible and elastic electronics, etc., are propelling the industry forward. Magnetic sensors operate on various physical principles, resulting in a wide range of specifications in terms of sensitivity, linearity, field range, power consumption, and cost. Sensors like Hall, AMR, GMR, and TMR are some of the commonly used magnetic sensors in different business verticals. Companies like Infineon, Crocus, NXP, etc. are responsible for continuous research and development of upcoming principles on magnetic sensors.

A magnetic sensor is an IC comprising a Magneto-resistant (MR) component that senses magnetic vectors and a magnet that takes care of magnetic vector biasing. Additionally, the sensing chip senses any change in a magnetic vector on the basis of variation in the MR component resistance resulting from the magnetic vector’s biasing. A magnet triggers magnetic vector biasing in association with the magnet body.

The rising adoption of robotics for factory automation, a new production paradigm, increasing human-machine interaction, and new Industry 5.0 policies are some of the key drivers of the need for magnetic sensors. These sensors ensure functional safety, reliable sensor information, a broader portfolio supporting different implementations, better quality, higher lifetime expectancy, and several other functionalities.

Why are They Preferred?

- They provide precise angle measurements in robot joints. As a result, their incorporation is critical in enabling next-generation autonomous robots with exquisite control over their actuators to ensure a close resemblance to human limb movement.

- Provides a low-cost, low-power replacement for classic rotational measuring systems.

- Alternative sensor technologies lack high refresh rates, near-zero latency, and high-speed digital interfaces required for power conservation data. They also lack real-time position feedback for an autonomous robot in an IoT environment.

- In PDU applications, high-voltage installations use Current Transducers (CT). However, when these CTs are inside oil-filled containers, they become susceptible to damage from temperature, moisture, and faults occurring at substations. Moreover, TMR magnetic sensors offer a simple solution to this problem.

Which Types of Magnetic Sensors Are Adopted?

Hall Magnetic Sensors

- The Hall element (Hall sensor) is a magnetic sensor that detects and outputs an analog signal proportional to the intensity of a magnetic field

- It’s mostly utilized for linear position detection and motor drivers

Anisotropic Magneto Resistance (AMR) Sensor

- The angle between the direction of the applied current and the magnetization of the material determines the resistance of some materials. This phenomenon is anisotropic magnetoresistance.

- Its miniaturization is simple. Additionally, its strong structure allows it to be manufactured on a plurality of substrates, including flexible and stretchable ones.

- Used in linear positioning systems due to their robustness

- Implement multi-frequency eddy current testing to discover faults in a Cu-Cr-Zr alloy used to build rocket nozzles in the non-destructive testing field.

- It is used in a disposable card-based system to detect the presence of the SRNA gene in the DNA of the bacterium Streptococcus.

Giant Magneto Resistance (GMR) Sensor

- Magnetic sensors use GMR (Giant Magneto-Resistive Effect) technology, where the measuring cell consists of resistors with ferromagnetic and non-magnetic layers.

- The major use cases of GMR are data reading from hard disc drives, biosensors, Microelectromechanical Systems (MEMS), and a few other devices.

- In addition, GMR multilayer structures find application as single-bit storage cells in Magneto-Resistive Random-Access Memory (MRAM)

Tunneling Magneto Resistance (TMR) Sensor

- It features a wide operating dynamic range, as well as strong linearity, minimal hysteresis, and sensitivity.

- It measures the current phasor of a single-phase AC application, including distance, harmonics, and conductor insulation.

Magnetic Sensor: Use Cases

- Robotic and factory automation

- Magnetic sensors provide exact and reproducible measurements in even the most difficult of situations, such as extreme temperatures and humidity levels, unclean or damp surroundings, and high-vibration applications

- Ultra-compact surface mount and through-hole packaging package them, enabling smaller robot joints and a lighter overall robot

- Magnetic position sensor ICs have in-situ programmability and high-speed digital interfaces that effortlessly connect to standard robot microprocessors

- They do not wear out since they are contactless

- They are less expensive than other rotational sensor technologies for robotics.

- Health care

- Anesthesia delivery machines, oxygen concentrators, dialysis machines, and infusion pumps all use magnetic sensors

- The use of hall sensors opens up new possibilities for developing MRI-compatible real-time magnetic tracking systems. MR-guided minimally invasive surgical instruments can integrate these sensors.

- The MPG (Magnetic Plethysmograph) sensor detects arterial pulses in the superficial arteries

- Magnetic sensors find their applications in biochemical detection, tumor detection, pathogen DNA detection, neuronal network sensing, drinking water contaminant detection, magnetic encephalograms, etc.

- Green Energy

- Magnetic sensors can be important for contactless current, angular position, and switch sensing in green energy power plants such as wind turbines and solar panel farms.

- Solar combiner boxes benefit from contactless current sensors, while angular position sensing is critical for optimal wind power generation.

- Electronic Devices

- Magnetic sensors are used in a wide range of electronic devices, including printers, scanners, cameras, and flat-panel displays.

- In mobile navigation, the electronic compass is a must-have feature for mobile devices. It includes smartphones and tablets, which are among the fastest-growing uses of magnetic sensors.

- Magnetic field sensors can also be found in-game consoles and a variety of smart gadgets

- White Goods

- Magnetic sensors provide the added intelligence for open/close door detection, fluid level, and contactless current sensing

- TMR sensors meet the high reliability and accuracy requirements demanded in new stringent appliance regulations for cooking and laundry appliances to vacuum cleaners and refrigerators

What Lies Ahead in Magnetic Sensor?

Here are some scenarios where the industry seems to be heading-

Materialistic Approach:

- Adding silver nanolayer: The magnetic sensor’s sensitivity can be increased by combining magnetic alloys along with silver nanolayers.

- Magnetic Tunnel Junction (MTJ) sensors are quickly becoming the technology of choice due to their high sensitivity, small size, low cost, and low power usage.

Miniaturization

- Integration of the MTJ element in the CMOS process results in the use of a smaller die, lower costs, and improved technical performance.

Combining Magnetic Sensor with Inductive Sensor

- A magnetic hall transducer gives an exact angle of 0° to 180° for angular detection. However, an inductive transducer provides a coarse angle of 0° to 360°. When these two principles are combined, superior range, compactness, and robustness are achieved. None of these are achievable when they are employed independently.

Conclusion

The rise in demand for IoT devices fuels the increased adoption of magnetic sensors. It also includes the increased adoption of electric and hybrid vehicles. Moreover, there is a rising need for high-quality sensing devices for Industry 5.0. Each type of magnetic sensor has its own set of capabilities. Thereby requiring the use of a plurality of sensors in complex use cases. Thus, there is a need to maintain the pace of development of magnetic sensor technology. It’s because it is essential to keep up with the upcoming use case of sensing technology. The top manufacturing companies in the sector include Honeywell, Analog Devices, Bunting DuBois, etc.