The use of foam-based delivery systems in the field of drug delivery is an innovative approach in the sector of pharmaceutical science that has brought a new dispensation of drugs through creative formulations. Foam-based systems do not use typical dosage forms; instead, they change liquid drugs into stable foams as soon as they are activated or applied, which improves their effectiveness and patient acceptance. This technology utilizes specific foaming agents and propellants to create foam, which has improved bioavailability, drug delivery to specific preselected areas, and enhanced patient compliance due to their ease of application and aesthetic appeal.

Research and Development Focus

Foam-based drug delivery systems are on the rise in modern medicine. For various applications, these systems have great potential for meeting unmet clinical needs and enhancing therapeutic results throughout various medical fields. The current research and development work related to this technique aims to refine foam technology to improve stability and precision and increase its scope of application in modern healthcare systems.

Principles of Foam Formation

Foam structure forms when gas bubbles are dispersed in a liquid or solid matrix. The foam structure functions as a reservoir for the drug in drug delivery, preventing its degradation and thereby soothing its controlled release. The stability and rheological characteristics of foams can be altered based on parameters such as surfactant concentration, gas pressure, and formulation viscosity.

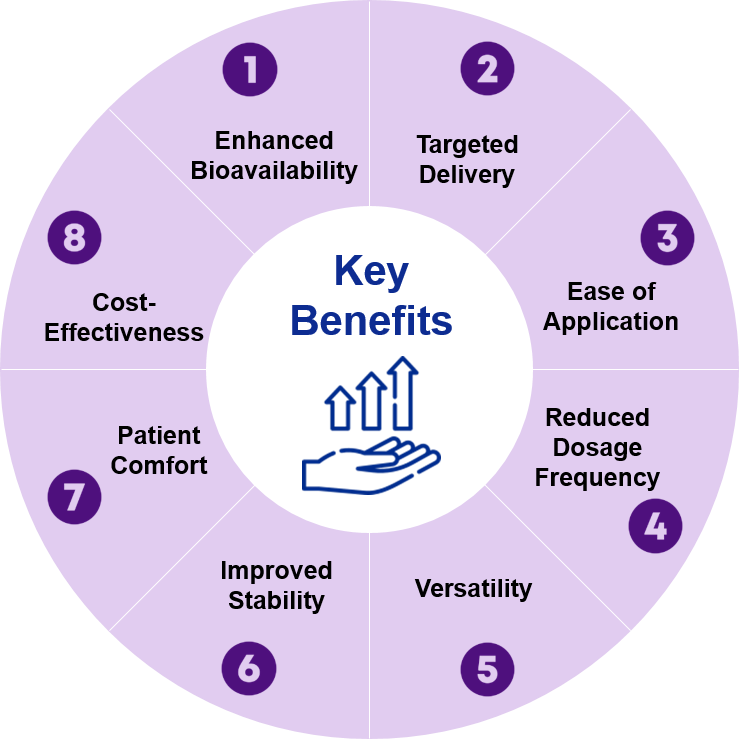

Key Benefits of Foam-Based Pharmaceuticals

Foam-based drug delivery technologies have various advantages over traditional dosage forms. Here is an exploration of the topic:

Figure 1: Key Benefits of Foam-Based Pharmaceuticals

- Enhanced Bioavailability: Foam can help poorly absorbable pharmaceuticals dissolve faster by increasing their surface area, allowing them to enter the body’s surface more easily. This provides improved drug delivery and possibly enables the use of less medicine for healing purposes.

- Targeted Delivery: Direct application of foams on certain parts of the skin, like wounds or mucosal tissues, enables drug delivery to be focused on that area. Utilizing this targeted approach can lower the occurrences of systemic effects and improve therapeutic results.

- Ease of Application: It is quite easy to apply foam-based drugs on uneven surfaces. This can enhance patient satisfaction, especially in treatments that must be applied multiple times a day.

- Reduced Dosage Frequency: Compared with traditional dosage formulations, foam formulations may need less frequent dosing during the treatment procedure due to the extended contact time and sustained release properties they possess.

- Versatility: Foam-based systems for delivering drugs can absorb different drug types, including water—and fat-soluble components. This flexibility allows the development of formulations suitable for the specific properties of drugs and therapeutic requirements.

- Improved Stability: Foams can guard sensitive pharmaceuticals from degradation and improve stability, particularly in topical applications where exposure to air, light, or other environmental factors may impact drug efficacy.

- Patient Comfort: Most foam formulations are non-greasy, non-sticky, and provide a pleasant feeling when touched. This makes patients feel more comfortable and satisfied while undergoing treatment.

- Cost-Effectiveness: Although the initial expenses for developing foam-based pharmaceuticals are higher, they can reduce overall healthcare expenses by improving treatment effectiveness, decreasing the need for hospitals, and improving patient results.

Foam-based pharmaceuticals altogether represent an encouraging opportunity in drug delivery, presenting benefits that may culminate in better healing results and care for patients in a wide range of medical applications.

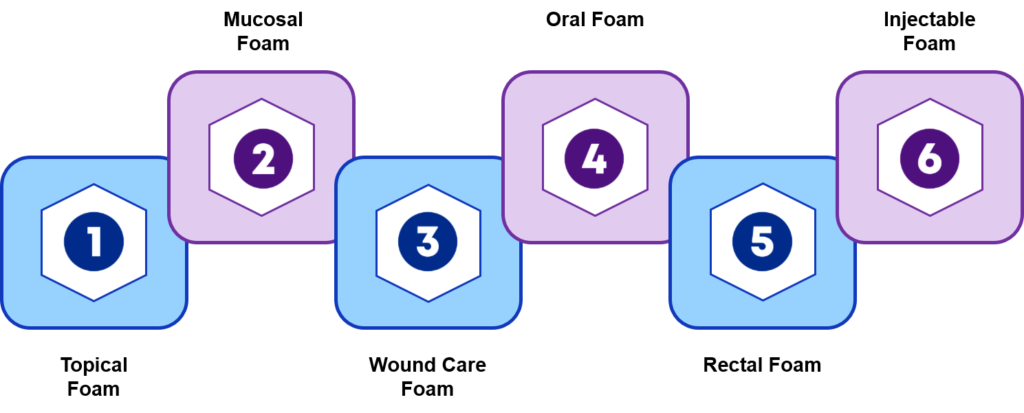

Types of Foam-Based Delivery Systems

There are various types of foam-based delivery systems, each of which is designed for specific applications and drug delivery needs. In various medical and pharmaceutical situations, drug delivery performance is bettered by making the delivery system for foam-based types suited for the purpose. The major types of foam-based delivery systems include:

Figure 2: Types of Foam-Based Delivery Systems

- Topical Foam: These foams are used for skin conditions and dermatological treatments. They may deliver drugs directly to infected areas, ensuring limited action and improved absorption.

- Mucosal Foam: Intended for utilization on mucosal membranes (e.g., nasal, rectal, vaginal), these foams convey drugs to these sensitive spots to boost their effectiveness on application.

- Wound Care Foam: These foams manage wounds by preventing infection, carrying pharmaceutical agents for quick healing, and having moderate evacuation levels, which helps optimize wound care.

- Oral Foam: Using these foams to deliver drugs through the mouth can be more convenient and improve patient compliance because they are used both for medication delivery and oral hygiene.

- Rectal Foam: These foams, particularly for rectal administration, can deliver drugs used to cure conditions like hemorrhoids and inflammatory bowel disease, offering localized therapy.

- Injectable Foam: These foams are suitable for particular applications like sclerotherapy or embolization, where drugs or therapeutic agents can be injected, thereby enabling localized treatments.

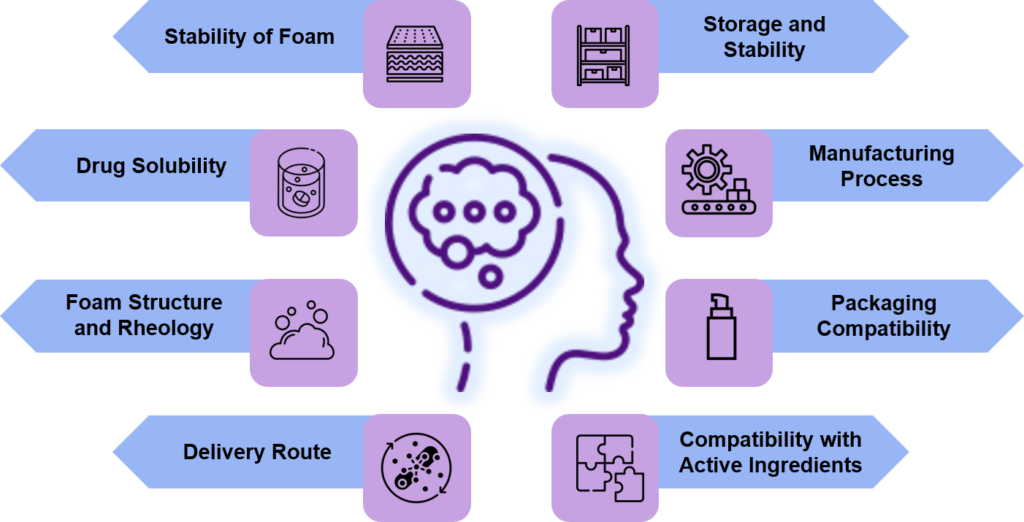

Challenges and Considerations

Foam-based drug forms are dosage forms that have several benefits and features and differ from conventional forms such as tablets and liquids. To ensure the successful development and commercialization of foam-based drug formulations, it is necessary to consider stability, compatibility, manufacturing processes, and regulatory requirements. Below are some critical formulation considerations for foam-based drug forms:

Figure 3: Challenges and Considerations

Stability of Foam: The stability of foam-based pharmaceuticals is of the utmost importance to ensure the drug is equally distributed throughout the formulation. Foam stability is generally affected by surfactant concentrations, viscous-modifying materials, and the gas used to create bubbles (such as nitrogen and carbon dioxide).

Drug Solubility: To guarantee equal distribution within the foam, the drug needs to be capable of dissolving or dispersing within the formula. If it is applied in the latter state, it is necessary to consider how well the substance can dissolve in liquids and gases.

Foam Structure and Rheology: The foam’s structure, including bubble size and distribution, and its rheological properties, such as viscosity and elasticity, influence its application and effectiveness. Modifying these properties could influence the release rate of medication materials and their stability.

Delivery Route: Foam formulations are flexible and can be adapted to serve different routes of administration like topical (skin) application, rectal administration, or sometimes oral administration. The formulation components and stability requirements depend on the route that is chosen.

Compatibility with Active Ingredients: If exposed to gases, foam drugs might react with the foam itself or deteriorate. It is important to conduct compatibility testing with active ingredients to guarantee that they are effective and safe.

Packaging Compatibility: Foam formulations typically necessitate proper packaging to uphold foam integrity while averting any leakage or collapse. Formulation components must be compatible with packaging materials and closures.

Manufacturing Process: Unlike traditional dosage forms, drug-containing foam preparations are generated using specialized machinery, which increases both the production cost and complexity.

Storage and Stability: Foam formations require particular storage conditions, such as temperature and light exposure, to remain stable and maintain shelf life. Therefore, stability studies are necessary to identify suitable storage conditions.

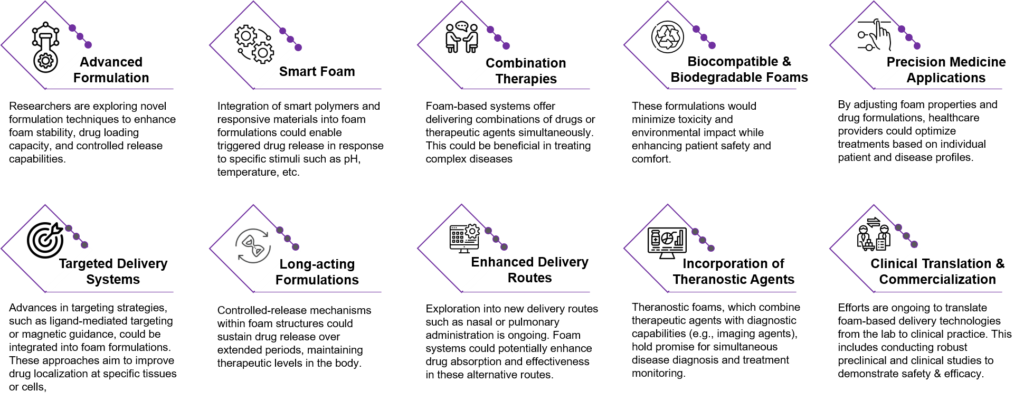

Future Directions and Innovations

In the upcoming days, foam-based drug delivery technologies can be concentrated by perfecting formulation processes, finding new application areas and merging emerging technologies such as nanotechnology and bioengineering. Research still finds a way to improve foam stability, control drug release mechanisms, and expand therapeutic options across various medical disciplines. Here are some areas that can be worked on, and innovations in foam-based drug delivery systems are given below:

Figure 4: Future Directions and Innovations

Market Drivers of Foam-Based Drug Delivery Systems

The unique properties of foam-based drug delivery systems have made them popular in different medical sectors and applications. A variety of market drivers contribute to the raise and acceptance of foam-dependent pharmaceutical delivery technologies:

Figure 5: Market Drivers

Potential Players Shaping the Domain/ Market of Cancer Vaccines

The domain of foam-based pharmaceuticals is quickly changing, and numerous potential players are contributing to it. These groups include pharmaceutical companies, CDMOs, universities, and research institutions. These players show a range of technologies and approaches in improving and developing foam-based drug delivery mechanisms. Working together is changing the future of the larger healthcare domain, aimed at developing strategies to improve patient outcomes. Below are various players, including Hartmann and Hollister, that are engaged in the development and commercialization of foam-based drug delivery systems:

Figure 6: Key Players Actively Working in Foam-Based Pharmaceuticals

Conclusion

In the field of pharmaceutical innovation, foam-based drug delivery systems are a lucrative field for leveraging their exclusive attributes that lead to better patient outcomes in different areas of medicine. Their non-invasiveness and their potential for applying drugs directly to exact places have minimized the total number of side reactions and increased the outcomes of medicine. Despite these promising attributes, more research is needed to fine-tune formulation techniques. The foam-based drug delivery systems appear as a valid alternative for the future of pharmaceutical innovation and hold great potential across many different medical applications. Further explorations and technological advances continually drive their global healthcare market adaptation and growth.