Alternatives To Li-Ion Battery

The proliferation of handheld devices, ranging from industrial measuring equipment to mobile phones, and the advancement of electric vehicles necessitated higher energy densities. Interestingly, Li-ion battery technology has advanced greatly in the last 30 years. However, the best Li-ion batteries are approaching their performance limits due to material restrictions. Thus, alternatives to li-ion battery is being found. Moreover, they also pose considerable safety risks, like catching fire if overheated. This results in higher costs as safety features need to be incorporated into the battery system.

Alternative materials and battery chemistry are being explored to go beyond Li-ion, including lithium-sulfur, sodium, magnesium, zinc, and dual carbon-based battery designs. Some more advanced technologies, like solid-state batteries, flow batteries, etc., play a vital role in the market.

Some battery manufacturing companies, such as Contemporary Amperex Technology Limited (CATL), Toyota, Gogoro, ProLogium’s, Ambri, etc., and some startups, like ViZn Energy Systems, Jena Batteries, ESS lnc, etc., are developing advanced battery systems that help in multiple applications, such as consumer devices, grid-level energy storage systems, electronic vehicles, aerospace, and many more.

Why Move Away from Li-ion Batteries?

Lithium-ion batteries are vital to the growing electric vehicle industry because they are lightweight, have a high energy density, and have a low lifespan cost compared to older alkaline-based batteries. There is, however, insufficient production of lithium-ion raw materials to meet upcoming demands. Within a few years, there will be severe restrictions on the lithium supply chain based on projections regarding the adoption of these technologies and miner investments. As governments throughout the world approve legislation to speed up the shift to electric vehicles and renewable energy, the shortfall will worsen.

Additionally, lithium-ion battery manufacturing has a strong market investment, which necessitates developing technologies and standardizing production procedures to enable low-cost, rapid conversion and scale-up using existing infrastructure.

Possible Alternatives to Li-ion Battery

1. Sodium-ion

Na-ion batteries, which have hard-carbon anodes and cobalt-free cathodes, are a low-cost, long-term alternative to Li-ion batteries for applications such as short-range electric vehicles and large-scale energy storage systems (ESS) in a world where wind, solar, and hydroelectric power are increasingly being replaced by battery energy storage for continuous, round-the-clock performance. The main benefit of Na-ion batteries is their long-term viability, which is critical in a world aiming to eliminate carbon-based energy sources.

Overcoming the problem of Li-ion battery

In the earth’s crust, the ratio of Na to Li is 23600 ppm to 20 ppm, and the cost of extracting and purifying Na is less than that of Li.

These use naturally plentiful transition metals such as iron, manganese, vanadium, and titanium without using cobalt, making Na-ion batteries sustainable and affordable. They are also used to make Na-containing metal oxide and polyanion cathode materials.

Alternatives To Li-Ion Battery: Drawbacks

Organic solvents in sodium batteries can generate major safety concerns such as fire or explosions due to their high flammability, similar to lithium-ion batteries.

2. Dual carbon

Dual carbon technology employs carbon in both the anode and cathode of the battery, providing a higher energy density comparable to lithium-ion but with a longer theoretical functional lifetime, enhanced safety, and significantly lower raw material costs. It charges much faster than typical Lithium-ion batteries and can be manufactured on current lines.

Overcoming the problem of Li-ion battery

Using a dual carbon battery will help stabilize market prices, as it employs carbon, which is readily available and not as hazardous as heavy metals.

The new dual carbon battery is environmentally benign and less expensive, saving overall battery costs and being environmentally friendly. The use of common carbon as an electrode active material and a current collector, rather than heavy metals, adds lightness and flexibility.

3. Zinc-ion battery

Zinc anodes and cathodes are used in zinc-ion batteries, another type of intercalation battery. With four-hour charge/discharging cycles and comparably sized battery packs, zinc-ion batteries could potentially last 15-20 years and perform similarly in terms of energy density.

The method employs a water-based electrolyte that is far safer than lithium, as zinc is another stable element that does not react with oxygen. Zinc, which is stable in air and compatible with aqueous electrolytes, is a less expensive and perhaps safer alternative to lithium and sodium, which both employ flammable organic electrolytes. A thick zinc foil acts as the anode and source of zinc ions in many rechargeable zinc-based batteries.

Drawbacks

The difficulty is that the extra zinc masks inefficiencies in the battery’s charging and discharging processes. It also raises the battery’s cost and is heavier than identical lithium-ion batteries.

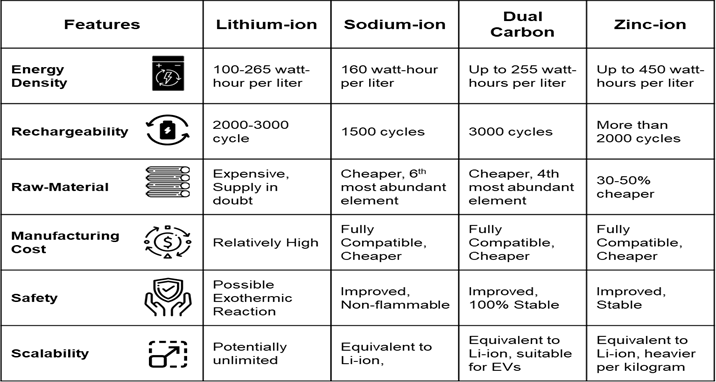

The table below determines which battery is best according to the manufacturer’s feature requirements.

Figure: Comparison of Li-ion battery with its possible alternatives

Advanced Alternatives to Li-ion Battery

A.) Solid-state batteries

In terms of technology, solid-state batteries constitute a paradigm change. In modern lithium-ion batteries, the ions flow from one electrode to another across the liquid electrolyte. Unlike conventional batteries, all-solid-state batteries have a solid electrolyte, but lithium ions can still travel through it. It has solid metal electrodes and a solid electrolyte. Solid-state systems reduce leakage and corrosion at the electrodes, saving design costs and minimizing the risk of fire by obviating the need for safety measures. Furthermore, the solid electrolyte architecture enables a smaller form factor, resulting in reduced weight.

How does it overcome the problem of Li-ion battery?

The first major benefit is a significant increase in cell and battery safety, as solid electrolytes, unlike liquid electrolytes, are non-flammable when heated. It allows for the use of cutting-edge, high-voltage, high-capacity materials, resulting in denser, lighter batteries with longer shelf lives due to reduced self-discharge.

It provides additional benefits at the system level, such as simplified mechanics, as well as thermal and safety control. Solid-state lithium-metal batteries are much lighter, more powerful, take up less space, charge faster, last longer, and pose significantly lower flammability risks than conventional lithium-ion batteries.

The solid-state batteries are projected to be approx. twice as energy-dense as existing li-ion batteries, which means automakers could theoretically require half as many cells to attain the same range as present vehicles. The batteries will also be able to charge faster.

B.) Flow batteries

A flow battery is an electrochemical conversion device that generates electricity by leveraging energy differences in the oxidation states of specific materials. Flow batteries are classified as redox, hybrid, or membrane-less.

How does it overcome the problem of Li-ion battery?

One of flow batteries’ most appealing features is their modularity. They can be modified to provide the necessary energy capacity by merging several electrolyte tanks or simply adding larger tanks.

In contrast to li-ion batteries, they are a good choice for big energy storage systems due to their scalability. Flow batteries can discharge the system for extended periods without affecting its capacity. The battery will not be permanently damaged even if the electrolytes unintentionally combine. This means that the Flow battery will last virtually indefinitely, as it will manage the storage system far longer than a lithium-ion battery, resulting in longer durations between the need to replace the battery.

Alternatives To Li-Ion Battery: Possible Roadmap for Next 3-5 Years

In the coming years, some batteries, like redox flow batteries, metal-anode solid-state batteries (beyond Li and Na), high-temperature batteries, seasonal battery storage systems, anion shuttle batteries, and many more, will provide various advantages in the energy management system. Essential benefits of vanadium redox flow batteries include long service life, no standby losses, low maintenance cost, environmental friendliness, fluctuating power demand, charging and discharging rates that do not affect the operation, and the ability to supply nearly infinite energy capacity by simply using larger electrolyte storage tanks. The battery won’t be irreversibly harmed if the electrolytes inside are accidentally combined. It can be kept completely drained for extended periods of time. Its electrolyte is aqueous, making it safer than its lithium-ion competitors, and it has a cycle durability of approximately 20 thousand. Therefore, flow battery systems are the right solution for complex energy management systems.

Zinc-iodine batteries (ZIBs), including zinc-iodine redox flow batteries and static ZIBs, are attractive prospects for grid-scale electrochemical energy storage in the future. They’re safe because they have a lot of theoretical capacity, energy, and power density. Self-discharge, sluggish kinetics, low energy density, and instability of Zn metal anodes are only a few of the challenges that must be solved before aqueous rechargeable ZIBs can be made practical.

Conclusion

The race has begun. As EV sales are rising, the need for high-density, long-life, and low-cost batteries is growing, resulting in a competitive solid-state battery market. The investigation of several materials and concepts is currently making significant strides. Metallic lithium, if correctly developed, could double the capacity of Li-ion cell technology. Metal lithium anodes have ten times the capacity of ordinary carbon anodes used in modern Li-ion batteries.

Small cells have already demonstrated the increased capabilities required of solid-state batteries, so it’s only a matter of time before larger battery production processes catch up. Once manufacturing catches up, technological developments will push it further, like liquid electrolytes and Li-ion batteries. As a result, materials and design strategies will probably change in the upcoming years to increase battery capacity.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.