Movement, silence, and motors are familiar and germane words for car manufacturers and steerer (s). This blog will focus on coupe motors and alternative fuels, a.k.a. car heat source (s). It is well documented that climate emergency, climate change, and global warming are all corollaries of the unabated use of fossil fuels. Alternative fuel ammonia is one of the instruments going forward.

A total of 1.474 billion cars, vans, and other vehicles contributed to the largest CO2 emissions in 2023. As per estimates by researchers, 2023 witnessed 40 billion-plus tons of CO2 release worldwide, and fossil fuels remained the major contributor with 37 billion tons of emission. Further, the three big Internal Combustion Engine (ICE) vehicle sales regions will be projected to produce 48,922 new units by 2025. Hence, compelled and propelled to cut down on CO2 emissions in the future, government/manufacturers/car users will push the growth of alternative fuels to a good 37% growth by 2050. Alternative Fuel Ammonia is the newest green fuel, and it is different from hydrogen and CNG, which car producers are exploring. This blog will consider everything around alternative IC engines fuelled by ammonia.

GAC Motor Makes First Alternate Fuel Ammonia-Powered Engine

The research and development team of Guangzhou Automobile Group Motor Co., Ltd (GAC) has pioneered an ammonia-fuelled ignition engine for passenger cars. The company achieved success in building the first ammonia-based engine with reliable fuel ignition. The engine produces a decent 160.92 hp and 90% less carbon emissions. Thus, to remove carbon, the development of ammonia as an alternate fuel is a great achievement for the transportation industry.

Need for Continuous Research in Green Fuel Ammonia

GAC is further tasked with getting the ammonia-powered engine environmental clearance, meeting safety needs, and becoming mainstream. Using ammonia as motor fuel generally is complicated, for if it is unburned, it would release other GHG (s) like nitrogen (NOx) and nitrogen oxide (N2O). Ammonia is difficult to ignite due to its high ignition energy (impacting efficiency), low flame speed (causing release of unburned ammonia), and slow chemical reaction due to lower chemical kinetics.

Possible solutions to these concerns include using blended fuels, preheating ammonia, and higher compressed ratios. The designing of the ammonia (NH3) engine and fuel-burning process needs careful iterations with respect to better injection design and combustion dynamics. Until the widespread adoption of ammonia as motive fuel becomes common, industry pundits, scientists, and naysayers will continue to have their burning questions and skepticism.

Compression Engines And Ammonia

Experiments are ongoing on using ammonia in compression ignition (CI) engines. In tests conducted with increased use of diesel and ammonia mix, it was seen that more NOx was released and showed reduced engine performance. Moreover, possible solutions to these challenges have been demonstrated using high-stability Diethyl Ether (DEE) and ammonia blends.

The higher percentage of ammonia leads to better brake thermal performance and combustion reliability. Another possible solution that has been tested is the use of Exhaust gas recirculation (EGR) to decrease nitrogen emissions. It was seen that increasing the compression ratio and intake strokes was necessary for improved engine functioning.

Future Demand for Alternate Fuel Ammonia

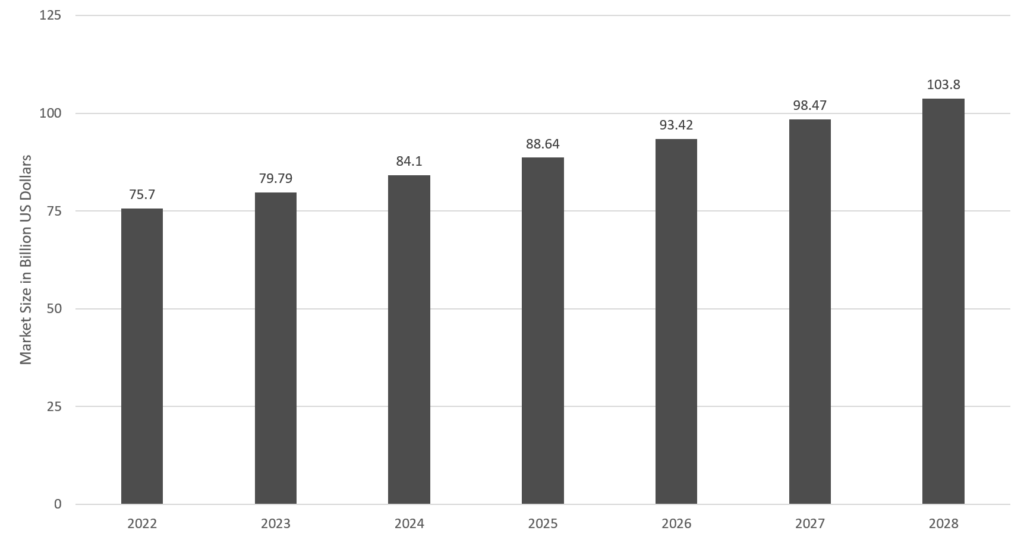

The worldwide market of ammonia is expected to reach $103.8 billion by 2028 from a 79.79 billion market in 2023, a CAGR of 4.6131%, as per Stellarix’s analysis. This growth is subject to increased demand for fertilizers, pharmaceuticals, chemicals, and transport fuel.

Figure 1: Market value of ammonia worldwide

Key Companies Exploring Alternative Fuel Ammonia

Many top companies are working on green ammonia and its innovative applications.

NYK’s A-Tug project

MAN B&W has recently achieved a milestone by developing an ammonia-powered, two-stroke, 4T50ME-X type engine. The MAN ES’s Research Centre Copenhagen (RCC) has tested it well for safety, heat-release, ignition, and harmful emissions. The company foresees a 27% increase in the use of ammonia fuel by large merchant-marine vessels by 2050. Höegh Autoliners is strongly committed to employing carbon-free fuel for its car carriers and using alternate fuel ammonia. Also, Hoeigh Autoliners has partnered with Norwegian North Ammonia to provide green ammonia to fuel their vessels.

NYK’s A-Tug project will see retrofitting the LNG-fuelled tugboat Sakigake into an ammonia-fuelled one built by IHI Power Systems, NYK, Japan Engine Corporation, and Nihon Shipyard. Below is the timeline of NYK’s A-Tug project:

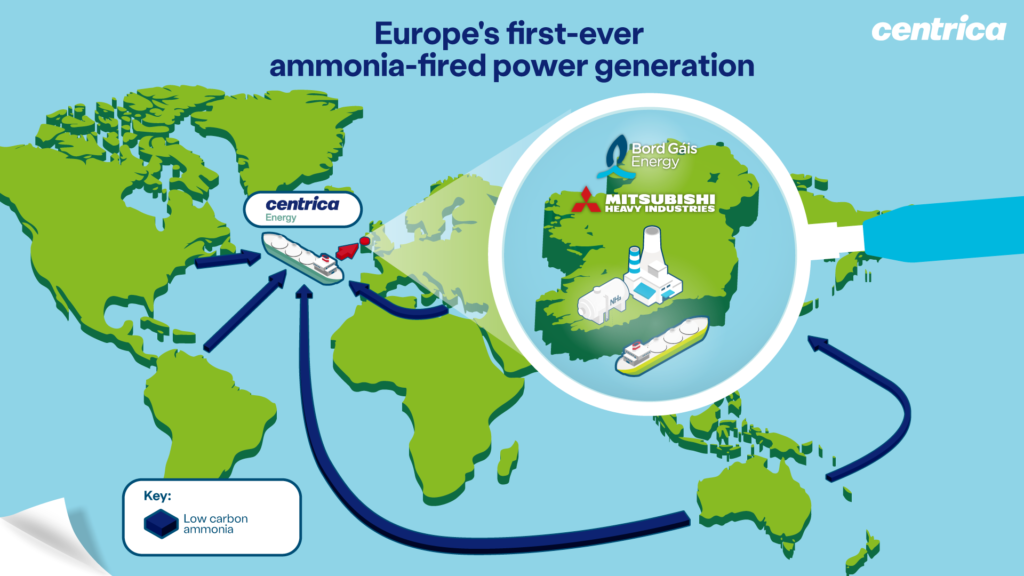

Boris Gáis Energy’s Whitegate Energy Station

A first-of-its-kind ammonia-fired power generation is being developed at Boris Gáis Energy’s Whitegate combined cycle gas turbine (CCGT) energy station in Ireland. The same is built with a partnership between three major entities: Boris Gáis Energy, Centric plc, and Mitsubishi Power Europe Limited. Low-carbon ammonia fuel will help in the much-needed clean energy transition.

Source: www.bordgaisenergy.ie

Figure 2: Europe’s ammonia-fired power generation plant in Ireland

Allied Ammonia will deploy Topsoe’s new dynamic ammonia technology for its e-fuel export energy project in Australia. Moreover, production is estimated to start in Q4 of 2028 and produce 900,000 tonnes per year.

Yara Eyde First Ammonia-Based Container Ship

It will act as the first ammonia-fuelled vessel to export products from Norway to Europe by 2026. Additionally, Yara Clean Ammonia has partnered with Yara Eyde to provide clean fuel for this carbon-free project. North Sea Container Line (NCL Oslofjord AS) and Yara Clean Ammonia are cooperating with the first ammonia-powered container ships. Enova has funded the project with NOK 40 million.

Other Ammonia Projects in the Pipeline

Wärtsilä, a Finnish propulsion system maker, modeled the first engine that runs on ammonia. The engine will be set up to power Viridis bulk carriers. First Ammonia, U.S.A, and Uniper, Germany, have joined hands on a green ammonia plant that deploys a unique solid oxide electrolyzer cell (SOEC). It is 30% more efficient than the traditional electrolysis process.

Conclusion

Engines are necessary, and so is fuel to power them. Most power-intensive industries, i.e., transportation and maritime, have used coal and petroleum for decades. Also, green change is happening slowly yet steadily in many global car manufacturing companies, shipping companies, and power-generating entities. Alternate fuel ammonia, in spite of being difficult to handle, is being explored cautiously and courageously. The total alternative fuel production will happen after a few years, whether green cars, ammonia fuel projects in Australia, or ammonia-based maritime engines.