Equipment & Manufacturing Processes

Driving Change in Manufacturing for Advanced and Sustainable Solutions

The Future of Making: Smart Manufacturing Consulting Solutions

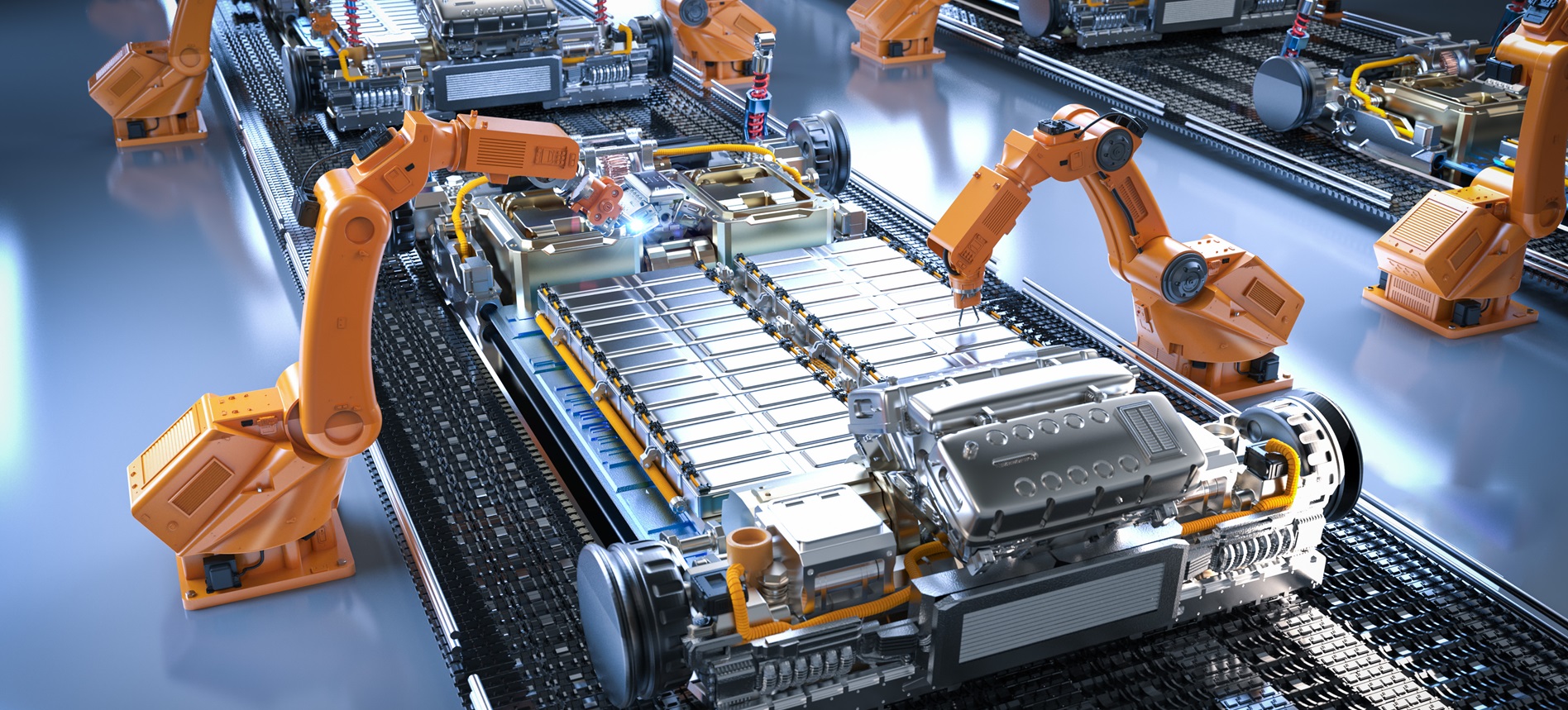

Manufacturing is an ever-expanding and progressive domain. Technological disruptions like Equipment-as-a-Service (EaaS), Big Data Analysis, and Hyper automation are revamping sales plans, technical fronts, organizational structure, and manufacturing & processing capabilities to establish Industry 4.0 dynamics, which will someday lead to Industry 5.0 and thereafter. Manufacturers are automating the data-collection process with the Industrial Internet of Things (IIoT) and utilizing predictive analytics to monitor equipment performance using a range of performance parameters. It allows them to guarantee peak performance and potential harnessing of equipment. An essential component of contemporary industrial manufacturing is automation. It helps businesses accelerate work processes and foresee issues that may hamper the manufacturing process. Also, manufacturers are prioritizing sustainability and carbon neutrality to align with climate change and increasing demand for green products and business practices. We offer experience and expertise to ensure safe navigation and resilience throughout the process.

Industry Trends

Manufacturing Trends

IIOT

Equipment-as-a-Service

Big Data Analytics

5G & Edge Computing

Carbon Neutrality

IIOT

IIOT walks hand-in-hand with technology and sustainability integration in manufacturing equipment and processes. From asset control to predictive maintenance, real-time monitoring, quality assurance, inventory management, and industry 5.0 integration, it is an upscaling transformation on all levels. As our manufacturing consulting team puts it, these applications will evolve further as smart manufacturing, micro-factories, and similar concepts take center stage to inculcate sustainability and Industry 5.0 basics in this niche.

How Can We Help You?

The headwinds emanating from industry 4.0 and 5.0 are challenging the industrial world’s growth and profit trajectory. The mandate for early enablement of innovation and technical expertise befalls all players, implying the need to act early for a strong market footing and competitive edge. Our industrial consulting services entail strategic guidance and support to nail informed decision-making, business transformation, and safeguarding growth and profits from disruptions in the foreseeable future. We furnish world-class services like market trends analysis, monitoring of emerging technologies, identifying competitors’ activities, benchmarking the company’s performance, anticipating risks, developing alternative future scenarios, assessing their potential impact, scenario planning, identifying key stakeholders, developing long-term strategic planning and setting investment priorities for the smooth execution of plans.

ExploreIndustries worldwide are looking to accelerate and streamline their operations. The scope for R&D and innovation expands as companies navigate challenges associated with complex automation systems, fragmented value chains, industry 4.0, and diversifying regulatory and market dynamics. Our manufacturing consultants are helping organizations capture market opportunities, navigate major future turbulences, and develop enough resilience to sustain business growth while addressing sustainability, regulatory, and economic complexities. Our innovation consulting team is well-equipped to address research & development, testing and validation, environmental innovation and sustainability, and digitalization requirements in the industrial ecosystem.

ExploreThe industrial sector is surging ahead in the shadows of automation, sustainability, and Industry 4.0. Companies aiming for market or technology leadership need to leverage these opportunities and claim a deeper footing in this domain. This raises the need to align strategy with these developments for long-term sustained results and profits. Our industrial consulting team combines technological expertise and industrial experience to help companies capitalize on emerging possibilities and gain a strong competitive edge. We analyze market trends and dynamics, look into the competitive landscape, perform strategic planning, relay opportunity identification, develop product roadmaps, ecosystems and partnership development, international expansion, data analytics implementation, portfolio, and product strategy to provide systematic advantages to investors.

Explore

Sustainability has emerged as a pivotal value differentiator that is quantifying brand equity, growth prospects, and resilience for various business verticals, including the industrial and mobility sectors. However, a gap between ideation and tangible reality awaits to be abridged as industry leaders navigate the undercurrents of circular economy, decarbonization, energy consumption, and resource conservation. As consulting partners, our industrial manufacturing experts are lending a helping hand to industry participants to integrate green standards in their product development, innovation, and company culture, along with answers to all “how to” related to services. We conduct comprehensive assessments that the environment may have, look into energy consumption, set sustainable goals, focus on circular economic strategies, resource utilization, product and process innovation, incorporate eco-design principles, electrification and alternative fuels, legal and regulatory obligations, and anticipate regulatory changes.

Explore

The manufacturing sector faces core challenges with respect to innovation acceleration, constricting GTM timelines, and rephrasing the product development process. This necessitates strategic partnerships and partner identification as they are key in turning innovative ideas into tangible realities. Our consulting team assists key players in staying agile, innovative, and competitive by pinpointing co-mans and partners. For clients, we evaluate potential partners, explore opportunities for co-manufacturing, shortlist strategic partners, facilitate discussions and negotiations, optimize the supply chain, identify potential suppliers and vendors, channel partnerships, technology licensing, market-entry, and potential international partners.

Explore

As the value chain stakeholders in the manufacturing domain strive to stay ahead of the curve, proactive technological innovation and benchmarking take center stage. The shift also demands swift and well-informed decisions to accelerate technical advancement, commencing a strong edge over niche-specific competition. As a strategic industrial consulting partner, we understand the challenge posed by the rapidly changing scenario in this respect, and we carry the ability to resolve all perplexing dilemmas with actionable insights, diligently curated benchmarking assessments, and proactive measures needed to thrive in this ever-evolving industry. From a startup acquisition perspective, Stellarix validates startup ideas, performs thorough market surveys, explores myriad revenue streams, go-to-target approaches, prototyping, and product development.

ExploreOur Experience

Landscape Study: EV Charging Station Management Software

A leading automotive company engaged with Stellarix to understand the EV charging software landscape and leverage the emerging growth opportunities. Our in-depth analysis enabled the client to prioritize its investments, partnerships, and technology adoption strategies for long-term growth. Client Background: A leading automotive company known for reliability, innovation, and sustainability Engagement Objective: The objective of […]

AI in Industrial Automation

A multinational company sought to enhance its portfolio with AI integration. Our team responded with a structured, insight-driven approach built on competitive intelligence, early research, and strategic opportunity analysis. Client Background: The client is a multinational industrial technology company specializing in energy management, smart manufacturing, and automation solutions. With a strong global presence and a […]

Edge AI for Traffic Management

A leading automation player sought to identify the most advanced Edge AI technologies supporting smart urban mobility and better traffic management. Our research insights enabled the client to make strategic investments and partnerships, improving their market position and capitalizing on available opportunities. Client Background: A leading automation company sought to explore and identify cutting-edge technologies […]

Client Queries Addressed

Q1. Which industries are leading the adoption of electrified machinery? Q2. What are the key technological barriers to widespread electrification? Q3. How does electrification impact the overall lifecycle cost of industrial machinery? Q4. What government incentives are available to support electrification efforts?

Q1. What are the key advantages of additive manufacturing over traditional methods? Q2. How does additive manufacturing impact material waste and production costs? Q3. Which industries are seeing the most significant benefits from additive manufacturing?

Q1. How do these materials enhance the performance and longevity of equipment? Q2. What are the environmental benefits of using new materials in manufacturing? Q3. Which suppliers are at the forefront of materials innovation for manufacturing equipment? Q4. How do new materials impact the total cost of ownership for manufacturing equipment?

Q1. How do these technologies enhance the efficiency and flexibility of manufacturing processes? Q2. How do smart factories impact the overall competitiveness of manufacturers?

Q1. How do digital twins enhance the design and prototyping of manufacturing equipment? Q2. Which companies are leading the development of digital twin technologies? Q3. What are the challenges in integrating digital twins with existing equipment and processes?

Insights

See All

Blogs

Articles

Articles

Articles