Solar Cars: A Far-Fetched Reality or Complete Truth?

Transportation constitutes roughly 27% of the total greenhouse gas (GHG) emissions. Governments across the globe are tackling this issue by setting stringent rules and regulations for IC engine vehicles and promoting the use of electric vehicles (EVs) by providing subsidies. However, EVs can potentially create a huge demand on the grid, burdening both the transmission and distribution systems. Solar cars, also known as vehicle-integrated photovoltaic vehicles (VIPVs), can reduce this. Here, we integrate PV modules into the vehicle’s exterior and connect them to electric loads or the vehicle’s driving batteries. This concept is still in the nascent phase as the mass-scale vehicle launch is awaited. However, a significant rise in research and development can be seen in recent years.

Solar Cars: Background & Market Implications

The concept of integrating solar modules in a vehicle has existed since the early 2000s. However, it still hasn’t gained traction in the market. Although benefits included relative cabin cooling when parked under no shade, a slight reduction in parking time, and lesser carbon emissions, they were all valued little compared to the elevated cost of a solar roof.

According to estimates, the solar vehicle market is projected to reach USD 689.5 million by 2027, with a CAGR of 18.1%.

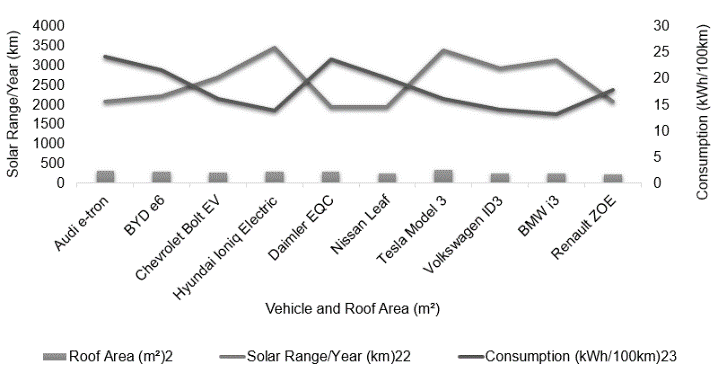

Toyota commercially launched Prius IV in 2017, with a solar roof of about 1 m2, generating a power of 0.18KWp. Other examples include start-ups like Sono Motors, Aptera Motors, and Lightyear, which plan to equip the roof and other body parts with photovoltaic material. We can account for the recent affinity by increasing the power density, thereby substantially raising the potential of power generated on a car roof. A significant extension in the driving distance of EVs is possible, along with the previous feature of cabin cooling. Another important catalyst is the cost of solar cells, which has decreased rapidly in the last 10-15 years.

For excellent insolation conditions, onboard solar may supply up to 70% of the vehicle’s energy needs, based on the current state-of-the-art extremely efficient solar cells (above 30% efficiency ideally) and a 3m2 accessible surface.

Solar Cars: Challenges & Solutions

Challenges: Specific automobile regulations are proving exceptionally challenging for the integration of photovoltaics into vehicle chassis; a few of the regulatory constraints are:

- Safety of the vehicle (accident safe, electrostatic discharge, vibration or fatigue, etc.)

- Acoustic emissions

- Recycling of the vehicle

- Purchase cost or lifetime profitability

The key technical barriers are:

- The usage of the generated power

- Large transmission losses and related safety risks

- Adding an improved battery management system

- Irradiance mismatch due to vehicle curvature

Solutions: Solar energy accelerates the transition to electric mobility. Vehicle-integrated photovoltaics is the natural next step toward zero emissions. This decade, solar mobility will provide energy on a gigawatt scale, which means millions of kilometers driven by solar power. That’s a huge release for the grid, the charging infrastructure, and the environment.

Integrating photovoltaics is achieved by a calculated approach that considers factors such as the area of rooftop or integrated surface areas, cell interconnection architectures, selecting the best cell module efficiency based on the design, such as flexible or curved, and also considering the weight of the integrated chassis along with the PV cells. Crystalline silicon-based PV modules offer lightweight PV modules with the highest energy density.

Electronic Architecture & Designs

Cut-cell interconnection systems have several advantages in EV applications. A curved shape can be embraced by the cells. Furthermore, smaller cells allow for the formation of higher parallel sections of cells in series for the same module voltage. Such architectures would help to lessen the impact of partial shadowing because the voltage follows a logarithmic relationship with the irradiance while the current is proportionate to the irradiance. PV technologies have different properties based on the application. Integrating module-level electronics (typically bypass diodes or MOSFETs) into the module laminate could make inserting modules in and on electric vehicles more accessible. The increased frequency of partial shadowing in EV applications compared to power plants necessitates considering a more resilient electrical architecture.

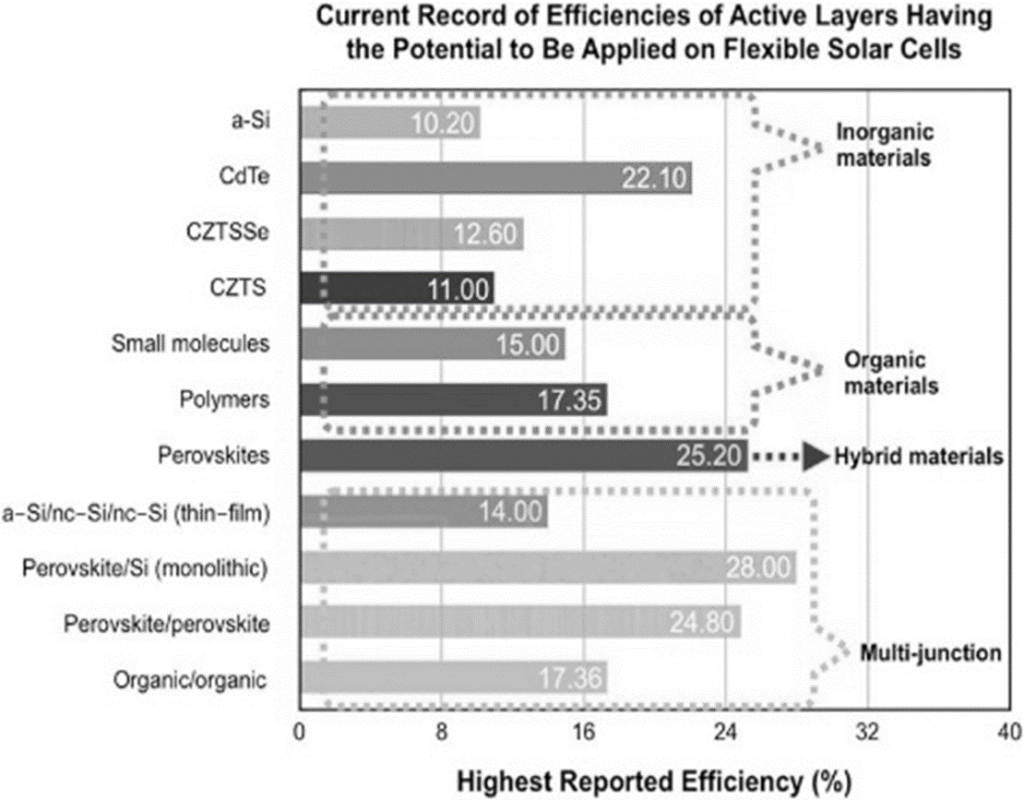

- Flexible Modules: These can be easily added onto the existing EV chassis. They include limited added weight but are the fastest way to integrate photovoltaics. Flexible PV module technologies have the advantage of lower weight (0.7 to 6.7 kg/m2) and power densities close to standard flat PV modules. They employ various technologies, from crystalline silicon-based cells to thin-film technologies such as copper indium gallium selenide solar cells or organic films.

- 3D Curved PVs: Glass/backsheet or glass-glass arched photovoltaic modules have a similar structure to standard PV panels with a thick front glass cover of 2.0 to 3.2 mm. This architecture utilizes 3D curved glass.

- Light Rigid PVs: With their lightweight design (weighing less than 4 kg/m2), they have the potential to be 3D curved and easily replace existing body chassis.

Ecosystem

Figure 3: Solar Car Ecosystem

Conclusion

Integrating photovoltaic systems into automobiles is not difficult, from production to usage to recycling. Production can use processes with minimal negative effects on the environment. We must optimize vehicle energy harvesting and consumption for the use phase. Techniques like excess energy transfer from vehicles to the grid can accomplish this. Likewise, we can identify creative strategies for recycling PV panels.

With the advent of perovskite-based photovoltaics, efficiency improvement paves the way for further research and development into vehicle-integrated photovoltaics. Also, light and rigid PV modules can replace a vehicle’s body parts. Furthermore, we can explore carbon capture device-fitted solar cars, as demonstrated by the students at Eindhoven University.