Impact of Copper Shortages on Semiconductor Industry

In recent years, the world has become increasingly reliant on technology, with semiconductors at the heart of many technological advancements. These semiconductor components power everything from smartphones and laptops to cars and medical devices. However, a concerning trend has emerged in the semiconductor industry – copper shortages.

Copper, a vital element in semiconductor manufacturing, is crucial in connecting and transmitting signals within these intricate circuits. It is used to produce interconnects, electrodes, memory chips, electronic devices, and wires connecting them. This article delves into the ramifications of copper shortages on semiconductor applications, exploring the causes, consequences, and potential solutions to this growing challenge.

The Role Of Copper In Semiconductors

Semiconductors are the building blocks of modern electronics, consisting of complex arrangements of transistors and interconnections. Copper, with its exceptional electrical conductivity, mechanical strength, thermal conductivity, and corrosion resistance, has been a staple material for interconnects that link these transistors. Its ability to efficiently transmit electrical signals with minimal resistance is paramount to the functionality and performance of semiconductor devices.

Semiconductor Industry: Causes of Copper Shortages

However, copper is also facing a global shortage due to several factors that have converged to create the copper shortages affecting the semiconductor industry:

- Increasing Demand for Electronics: The digital age has driven an insatiable demand for electronics, from consumer devices to industrial applications. The rapid proliferation of technologies like 5G, the Internet of Things (IoT), and digital economy and artificial intelligence has fueled the need for more powerful and efficient semiconductor components, placing higher demands on copper supply.

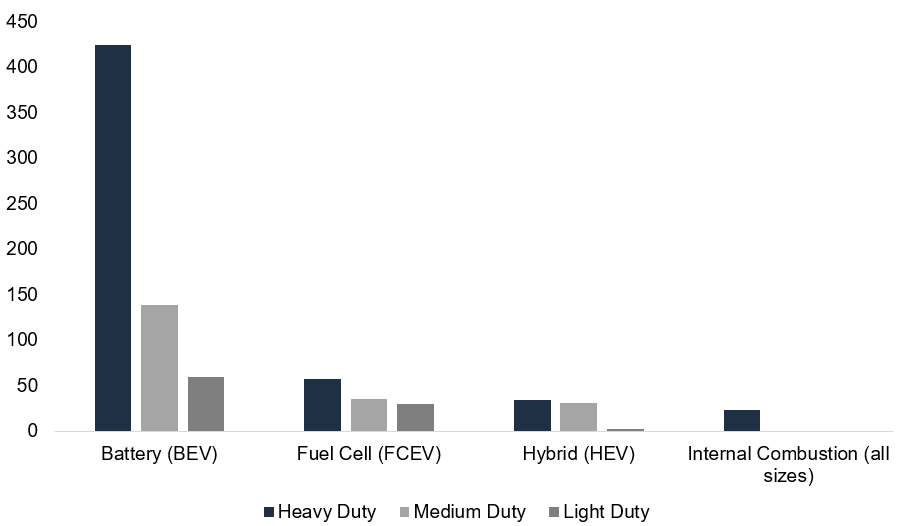

Current copper content by vehicle for key powertrains (Kilograms of copper per vehicle)

Figure 1: Copper Content For Electric Vehicle

- Supply Chain Disruptions: The COVID-19 pandemic exposed vulnerabilities in global supply chains. Shutdowns, restrictions, and workforce shortages disrupted copper mining, processing, and transportation, leading to supply chain bottlenecks in the semiconductor industry.

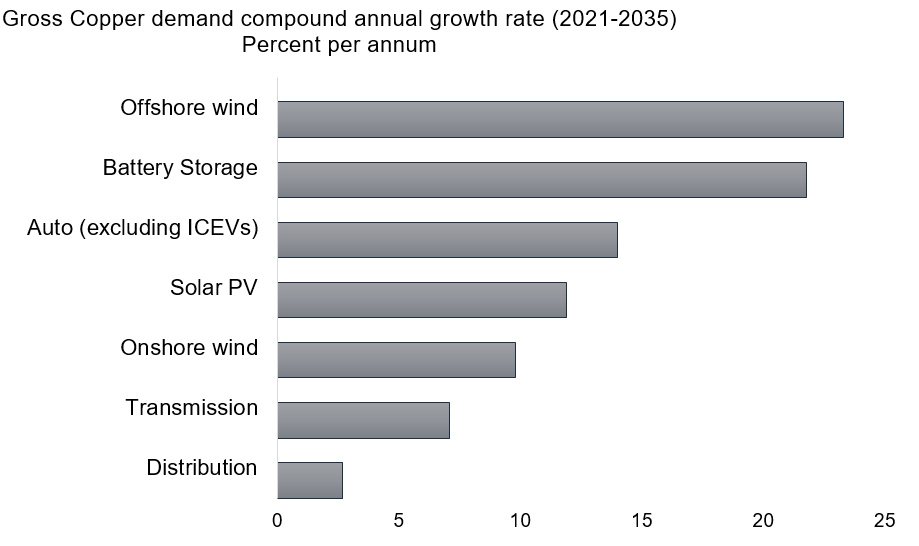

- Energy Transition: The global push towards renewable energy sources like wind and solar power relies heavily on copper for wiring and connections. This increased demand for copper in the energy sector further strains available supplies.

Figure 2: Gross Copper Demand

- Geopolitical Factors: Trade tensions and geopolitical conflicts can disrupt the flow of raw materials, including copper, affecting supply chains and causing uncertainty in the semiconductor industry.

- Clean Energy Requirement: The push for clean energy has increased the demand for copper, a vital component in renewable energy technologies such as wind turbines and solar panels.

- Deterioration in Copper Ore Quality: The declining quality of copper ore presents increased challenges in the extraction process.

Impacts of Copper Shortage on the Semiconductor Industry

The shortage of copper has far-reaching consequences for semiconductor applications and the technology sector as a whole:

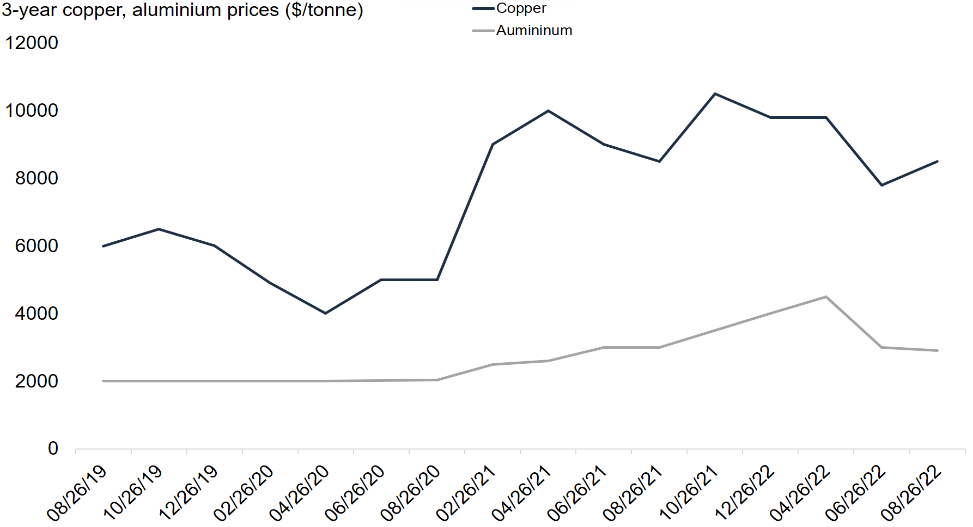

- Rising Costs: As supply struggles to meet demand, the cost of copper has surged. Semiconductor manufacturers, already dealing with thin profit margins due to intense competition, now face increased production costs, potentially leading to higher consumer prices for electronics.

Figure 3: Copper Pricing

- Production Delays: Copper shortages can disrupt production timelines, delaying the release of new semiconductor products. This delay could have cascading effects on various industries that rely on these components, from automotive manufacturing to healthcare equipment.

- Reduced Performance: Copper shortages may force semiconductor manufacturers to explore alternatives with inferior electrical conductivity. Substituting materials could compromise semiconductors’ performance and reliability, impacting their functionality and longevity.

- Innovation Slowdown: The shortage of a critical component like copper could hinder innovation in the semiconductor industry. Research and development efforts might be diverted towards finding solutions to the copper shortage rather than pushing the boundaries of semiconductor technology.

Potential Solutions And Mitigation Strategies

Addressing the copper shortage requires a multi-faceted approach that combines supply chain resilience, technological innovation, and sustainable practices:

- Diversification of Suppliers: Semiconductor manufacturers can mitigate supply chain disruptions by diversifying their sources of copper. This reduces reliance on a single supplier or geographic region, enhancing resilience in the face of global uncertainties.

- Recycling and Circular Economy: Encouraging electronic waste recycling can alleviate some pressure on the copper supply. Implementing circular economy principles can reduce the need for virgin copper while minimizing environmental impact.

- Material Substitution: Researchers are exploring alternatives to copper, such as materials with higher electrical conductivity or lower susceptibility to shortages. Transitioning to these materials could help mitigate the effects of copper scarcity.

- Efficiency Improvements: Semiconductor manufacturers can work on designing more efficient and compact circuits, reducing the overall amount of copper needed in each device. This approach not only conserves resources but also enhances the performance of electronics.

Bridging The Copper Supply Gap

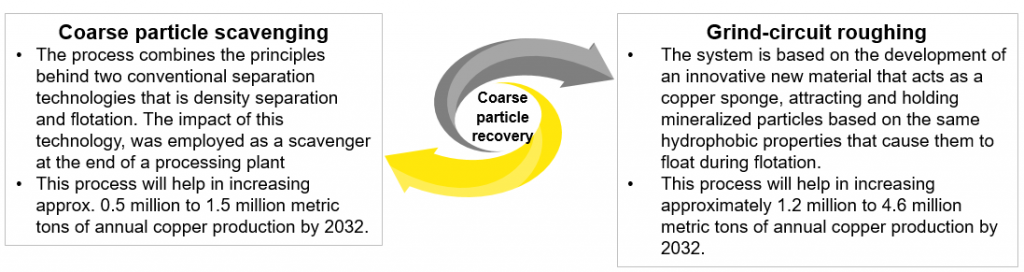

With the demand for copper rapidly increasing, new processing technologies will help meet the shortfall in supply from existing operations. Coarse particle recovery and Sulfide leaching are some technological developments that can contribute meaningfully to bridging the supply gap.

In 2022, global refined copper usage reached a record high of almost 26.1 million metric tons, marking a notable three percent increase compared to the previous year and representing the highest reported figure since 2010.

Coarse Particle Recovery

This is a process of efficiently capturing and extracting larger-sized particles in various mineral processing operations. The process will improve energy efficiency, reduce water consumption, and enhance overall processing efficiency in mining operations. Two prominent approaches to coarse particle recovery are:

- Grind-circuit roughing

- Coarse particle scavenging

Figure 4: Coarse Particle Recovery Process

Semiconductor Industry: Sulfide Leaching

The flotation-based process is used in sulfide leaching; the process is economical for ores with levels of copper greater than 0.25 percent, from which flotation can recover 85 to 90 percent. This process recovers the copper from material below mill head grade, which is considered waste. This process help in increasing the demand for copper by 2.4 million metric tons per annum by 2032.

Conclusion

The copper shortages impacting semiconductor applications reflect the intricate and interconnected nature of today’s global supply chains. Addressing supply chain vulnerabilities is crucial as the world becomes increasingly dependent on technology. The semiconductor industry must collaborate across sectors to develop sustainable solutions, ensuring a stable supply of critical materials like copper. Only through innovative strategies and collective efforts can we maintain the momentum of technological advancement while safeguarding against the disruptions caused by material shortages.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.