Robots in Manufacturing: Autonomy, Design, Advanced Materials

Autonomous robots have the capability to navigate autonomously and adjust to diverse situations, in contrast to traditional industrial robots, which are engineered to execute repetitive tasks in a fixed place. Robots in manufacturing prioritize sustainability and energy efficiency in design. With advancements in AI/ML, automation and precision can be enhanced. The demand for advanced manufacturing grippers grows to automate processes and reduce manual workloads.

SCARA, Delta, Cobots, and Cartesian are commonly used robots in manufacturing industries. They are controlled using vacuum, pneumatic, hydraulic, and electric techniques. These robots are used for pick-and-place operations, handling, palletizing, and assembly.

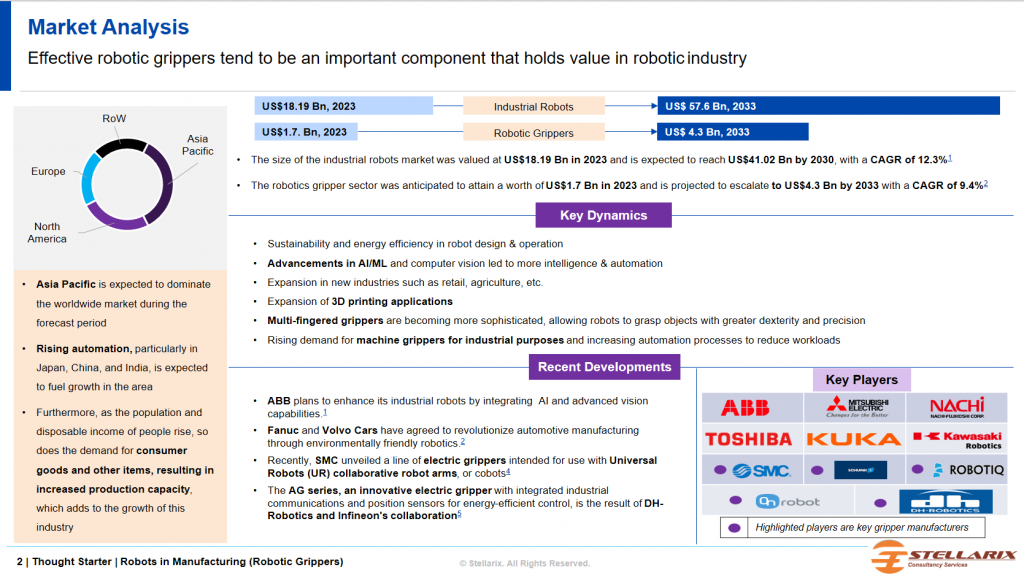

The industrial robots market was valued at 18.19 USD Bn in 2023, and it is forecasted to grow to 41.02 USD Bn by 2030, boasting a CAGR of 12.3%. Similarly, the robotics gripper sector, valued at 1.7 USD Bn in 2023, is expected to rise to 4.3 USD Bn by 2033, with a CAGR of 9.4%.

Figure 1: Market Analysis of Robots in Manufacturing

- ABB plans to enhance its industrial robots by integrating AI and advanced vision capabilities

- SMC Corporation is the leader in providing collaborative robot grippers to key players like FANUC, Yaskawa, Mitsubishi Electrics, etc. SMC robot grippers are compact and lightweight, with comparatively high gripping force due to air operation and a high-precision linear guide.

- Bedeschi’s R&D team has developed grippers that are lighter and stronger, capable of preventing wear and guaranteeing grip elasticity to avoid product damage

- Design, advanced materials, and integrated components are the main areas of focus in the R&D of robotic grippers

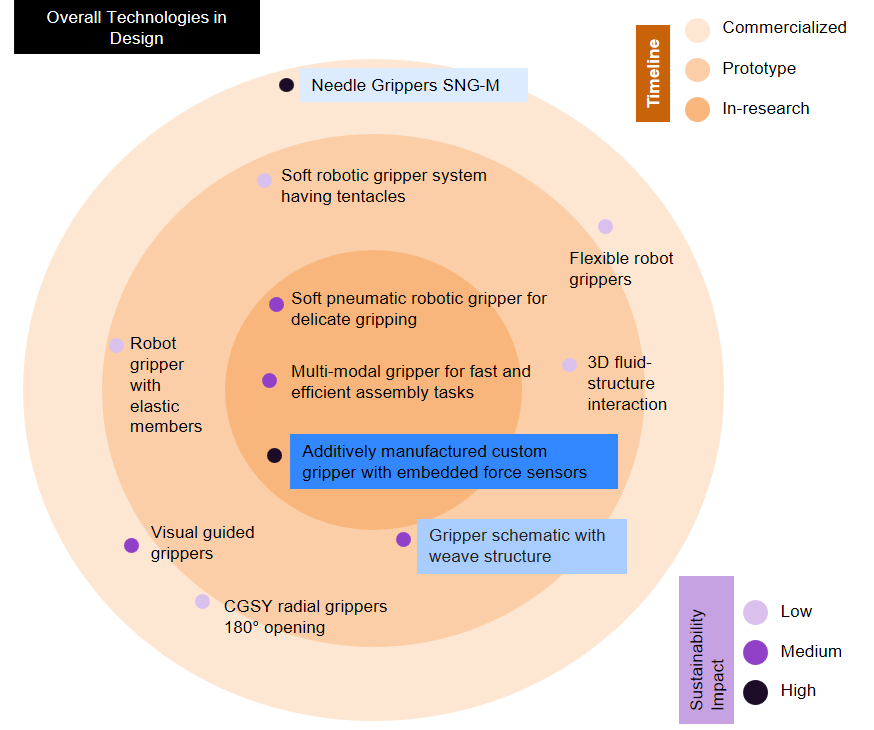

- The sustainable robotic gripper, crafted from eco-friendly materials such as PCL and PLA, prioritizes safety, modularity, and flexibility. Its durability and affordability drive widespread adoption, fostering a circular economy and advancing sustainable development goals.

- The ground-breaking advancements in haptic feedback, AI integration, and materials science will drive innovation in the robotics grippers market

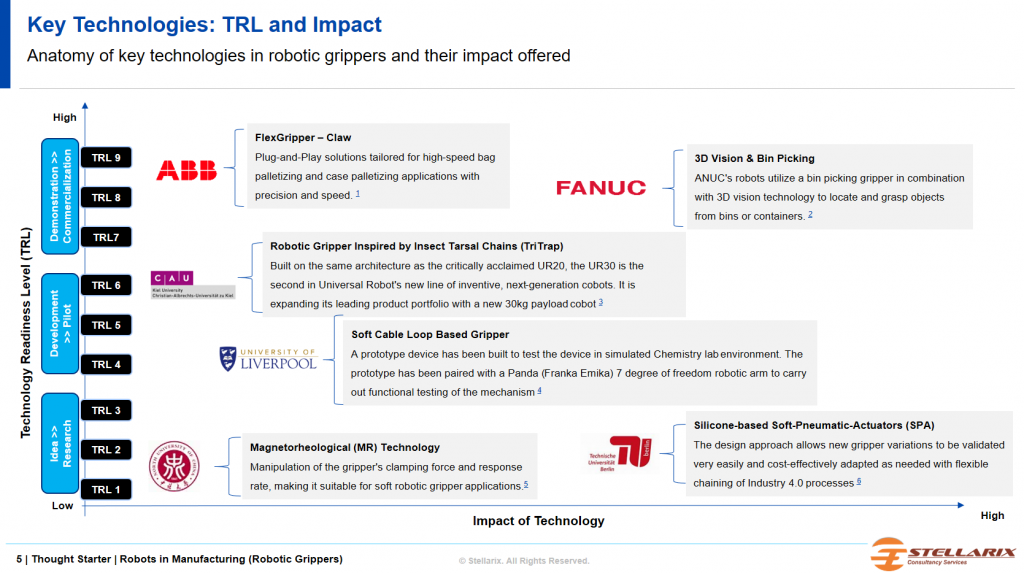

- The 3D vision & bin-picking technology developed by FANUC utilizes 3D vision technology to locate and grasp objects from bins or containers

- The OnRobot’s RG2-FT gripper boasts built-in sensors for precise automation, aiding in correct part mounting during assembly. It detects slipping risks and offers customizable fingertips for versatility.

- Festo’s GripperAI software allows blind bin picking and autonomous handling with different robots and gantries. Its sophisticated AI technology enables flexible and adaptive production processes by effectively capturing any part.

Figure 2: Key Technologies

- INNOCISE and SCHUNK gained international support for their green and efficient technology in robot grippers, where it has integrated tiny polymer chains for gripping, eliminating the external power as it adheres to the surface without pneumatic or electrical assistance

- A design technique developed by the Technical University of Berlin for Silicon-Based Soft-Pneumatic-Actuators (SPA) makes it possible to evaluate gripper modifications for soft robot grippers with limited payload capacity quickly and affordably

- With accuracy and speed, ABB’s Flex Gripper-Claw offers a seamless plug-and-play solution designed for high-speed bag and case palletizing applications

- The National University of Singapore developed a wooden robotic gripper prototype that adapts to hot environments while maintaining a gentle touch. It operates on moisture, temperature, and light changes, reducing energy usage.

- The TriTrap gripper developed by Kiel University is a versatile, robust, and cost-effective device using under-actuated digits with passive conformation. It securely holds various objects of different sizes, weights, and shapes without requiring further optimization.

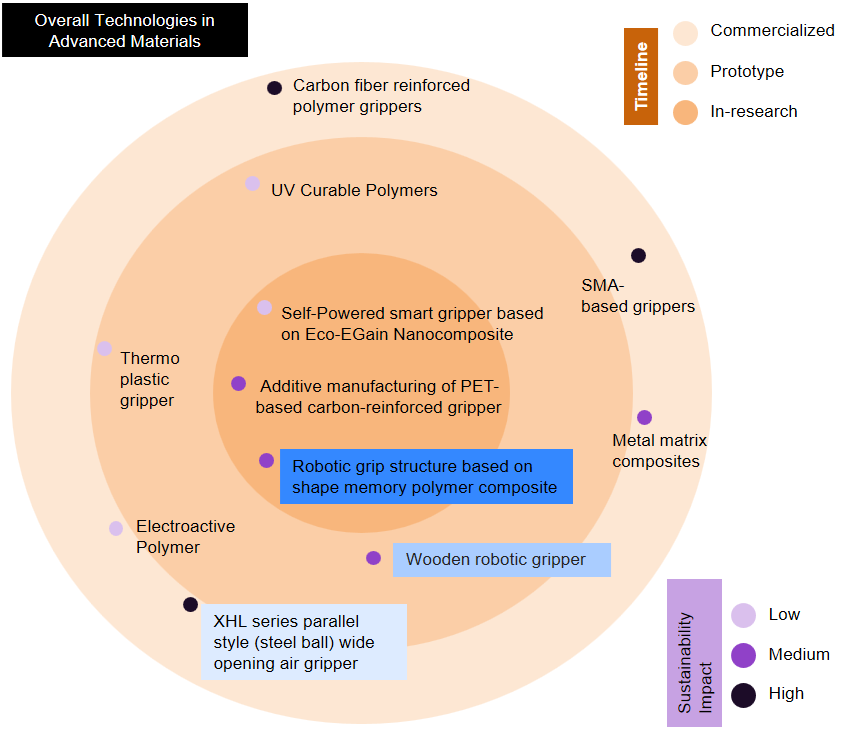

Figure 3: Overall Technologies in Design and Advanced Materials