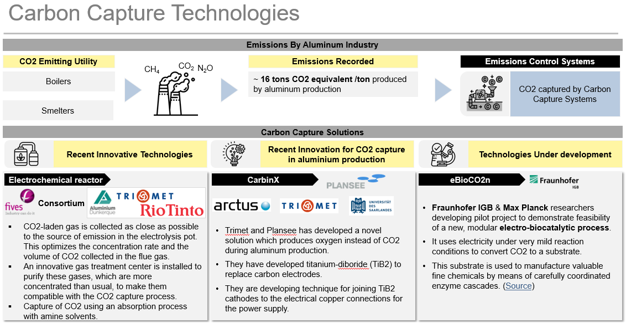

In this case study, we embark on a journey into the world of technology scouting, with a keen focus on ‘carbon capture’ solutions within the aluminum production industry. With the insights gained from extensive consulting experience, we navigate the intricacies of this field, exploring innovative ways to curb the carbon footprint of aluminum manufacturing. As global environmental concerns intensify, our exploration underscores the pivotal role technology scouting plays in shaping a more sustainable future for aluminum production while addressing the crucial keyword ‘carbon capture.

Industry

Aluminum Production

Client Overview

The client is a multinational company that is the world’s one of the largest metals and mining corporation.

Objective

The client was interested in identifying commercial as well as under-research technologies for reducing CO2 emissions from aluminum production process. The client was interested to evaluate the efficiency of the CO2 capture processes to finalize technology and deploy it at their plant.

Outcome Snapshot

Business Impact

The process diagram highlighted key areas where the carbon footprint is high. This helped the client to understand areas apart from exhaust gases that lead to CO2 emissions.

Comparison of commercialized technologies and under-research technologies basis their CO2 capture efficiency helped the client to shortlist vendors from whom they could purchase the technology as well as companies with whom they can partner to further develop the under-research technology.

The client also gained insight into startups with good technologies and patents, which they intend to capitalize on by investing in those companies.