Smart Mineral Beneficiation: AI-driven Testing for Optimal Resource Recovery

Is Your Operation Hitting a Physical Limit?

The mineral extraction process is a crucial part of the global industry, spanning electronics, construction, energy, and manufacturing. For decades, the industry has depended on balanced mechanical and chemical precision. However, depleting ore grades and increasing mineralogical complexity are pushing traditional methods to their limits, creating a need for new solutions that offer real-time outputs and improved efficiency.

The industry has reached a point where building more mills or adding more chemicals is no longer the solution, making AI the new digital pathway to recovery. AI-driven testing has become a groundbreaking method that minimizes environmental impact, reduces waste, optimizes resource use, and provides real-time data. Operations are changing to become safer, less time-consuming, more efficient, and more sustainable.

Stellarix assists clients in finding tailored solutions for their challenges, including technology integration and partner collaboration, to improve the mineral extraction process and stay competitive.

The Intelligence Behind Recovery: How AI Sees and Solves

AI and Machine Learning have moved beyond the laboratory and are actively transforming industries by providing unprecedented accuracy and cost-effectiveness.

- Artificial Neural Networks (ANNs): For on-site mineral analysis where rapid identification without time-consuming pre-processing is required, ANNs are a viable option.

- The Advantage: ANNs enhance the capabilities of feature extraction from unprocessed data, including spectroscopic and imaging data

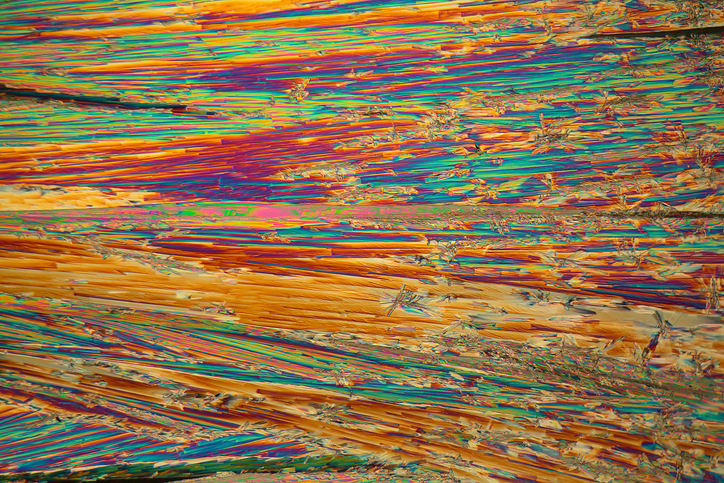

- Convolutional Neural Networks (CNNs): CNNs excel at visual inspection and areeffective for analyzing visual data, such as images or spectral data, with great precision.

- The Advantage: By handling the complex and intricate data automatically, it reduces the need for manual interventions, allowing faster operations with fewer bottlenecks.

Where is the Value: AI in Different Mineral Beneficiation Processes

- Comminution (Crushing & Grinding): The AI-optimized semi-autogenous grinding (SAG) mill boosts output by 4.42% and lowers energy consumption by up to 7.62% through the use of statistical analysis and machine learning (ML) techniques.

- Chemical and Mineralogical Analysis: AI-assisted multi-energy X-ray imaging and laser-induced plasma spectroscopy support continuous and precise mineral content monitoring. While ME-XRT determines basic information about the overall item volume, LIPS analyzes the surface’s chemical composition.

- Automated Mineralogy (SEM-EDS): Using chemical composition and texture data from SEM-EDS, AI classifies minerals with 92–98% accuracy using Support Vector Machines (SVMs) for mineral classification and Convolutional Neural Networks (CNNs) for picture analysis.

- Automated Mineralogy (EPMA): Since the electron probe micro-analyzer (EPMA) relies on manual analysis, AI-driven processes help to automatically map elements and identify phases, saving about 50% of the time.

Are you interested in understanding the CapEx and ROI related to AI integration in beneficiation? At Stellarix, we assist our clients in identifying the most suitable technology for their specific mineralogy, highlighting value drivers that generate substantial ROI with manageable CapEx.

Innovations for Future Proofing Recovery

Mineral beneficiation is rapidly evolving with AI, automation, and smart sensing transforming ore analysis and processing. Staying ahead of these trends makes the difference between a future-proof asset and a legacy bottleneck. Stellarix supports this transition by identifying cutting-edge technologies, mapping emerging research trends, and evaluating high-impact innovation pathways.

Key research innovations are:

- Hybrid Intelligence (PINN): Researchers at Aalto University are advancing beyond “Pure” AI by combining deep learning with physics-based models to improve the accuracy of flotation process predictions. The PINN is trained using data from a digital twin that mimics real flotation cells, incorporating both actual plant data and physics-based simulations. This innovation enables precise predictions, enhancing automated control and optimization of mineral processing plants, and increasing the efficiency and recovery of valuable materials like gold. (Source)

- Smart Sorting: Managing the complex ores is challenging, and if they are stuck together, it becomes even more complex to sort them. China University of Mining and Technology is solving this using a multi-step approach, where first, the images are converted to black-and-white using an automatic threshold, and the edges of the ore are detected. To find the curved-in (concave) points on the ore’s outline, special techniques are used, and the “three-wire method” helps reduce errors from irrelevant points. Tiny noise spots are removed using shape and size filters. This allows the system to correctly separate ore pieces that are stuck together. For classifying different types of ore, it uses an innovative training approach with transfer learning, starting from a deep learning model trained on another dataset. Some parts of the model are reset to better fit the ore data, and then fine-tuned using the new dataset. This approach works well even with limited data and avoids unnecessary parts of the original model. (Source)

- Temporal Awareness: This method uses ConvLSTM, a special neural network that combines CNNs (which analyze images) and LSTMs (which capture time-based patterns). By processing video data of the froth, the ConvLSTM model can understand both the appearance of the froth and how it changes over time, improving analysis and control of the flotation process. (Source). In partnership with the Managem Group, the model was tested at a site where lead, copper, and zinc are separated. It improves flotation monitoring by being more precise, cheaper, and easier to maintain than current methods. It provides real-time information on mineral quality, enabling control and optimization of the flotation process.

Real-World Impact: From Theory to Throughput

Case 1: Reducing Failure Events: Unwanted mill stoppages and overloads happen because the operator cannot see what’s going on inside. The IntelliSense.io enables the operator to foresee what is going to happen. Using IntelliSense.io’s Scientific-AI, operations can now predict mill performance 20 minutes ahead.

Result: It boosts throughput by 1% by keeping the circuit productive and reducing the frequency of mill shutdowns.

Case 2: Removing Operator Bias: In mining operations, flotation is a crucial process. However, there are issues with the current manual control of the flotation process, including differences in recovery and grade caused by operators’ disparate operating philosophies. SentianController, an AI-assisted solution developed by SentianAI, helps optimize the flotation process. It analyzes past and current data using prediction models, an imitation model, and inferred system dynamics. To determine the ideal set points based on the current process state, it considers both historical and prospective data.

Result: By providing operators with optimal sets and anticipated process outputs, it improves their decision-making, thereby increasing the recovery rate of precious minerals.

Navigating the Ecosystem

The market is currently flooded with many AI solutions; however, the key challenge for any organization is to filter out noise from value. Companies like Luffy.ai are providing adaptive intelligence that not only follows rules but also adjusts to mine changes.

Luffy.ai’s Industry Applications of Adaptive Intelligence in Mining and Minerals reduce energy use and environmental effects while increasing production output and yield. Their Neural networks optimize processes and streamline resources by continuously analyzing data from sensors and equipment, which raises profitability, quality, and productivity. To assist manufacturers in adjusting to variation and increasing the robustness of their plants, adaptive intelligence provides potent new control and optimization tools. The system can be scaled up to complete plant optimization or applied to a process’s primary control loops.

Last Words: Future is Predictive Recovery

The industry is currently moving toward automation and a data-driven ecosystem. Mineral beneficiation is undergoing a shift driven by AI-driven testing and process improvements.

By embracing AI, mining companies can gain three key benefits: Resource Optimization, Waste Recovery, and Real-Time Decision-Making. While AI-optimized automated mineralogy can save about half the time and classify minerals accurately, AI-optimized communication procedures can boost output and lower energy consumption.

Stellarix is supporting this transition by identifying cutting-edge AI models, evaluating solution providers, and mapping adoption pathways for mining operations.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.