From Performance to Purpose: The New Age of High-Performance Polymers

Beyond the Benchmark Performance: Why High-Performance Polymers (HPPs) Need Reinvention

High-performance polymers (HPPs) have dominated applications where commodity plastics fail for decades. Their potential to perform at extreme temperatures, resist chemicals and wear, and be lightweight has made them one of the top choices for applications ranging from electronics to medical spaces, where even metals or commodity plastics fail to match.

Over the past few years, the sector has seen significant growth, with the HPP market expected to surpass $60 billion USD worldwide by 2030. Since these polymers enable more precise engineering for critical, small-volume, high-value applications, like spinal cages and semiconductor tool parts, the low production volumes keep the per-kg costs high and limit supply to only a few global companies.

Despite improved performance, there are still some limitations. For example, the inherent strength of HPPs, which is crucial for demanding applications like aerospace and medical fields, can also be a double-edged sword. This strength presents challenges, including difficult processing and recycling, limited resistance to certain chemicals (such as H2 permeation or electrolyte attack), and regulatory pressures on fluorinated chemistries. Currently, the exciting story is how challenge-driven innovations ranging from 3D-printable PEEK implants to ultra-pure fluoropolymers for semiconductors are bridging these gaps and enabling tangible, application-level shifts across multiple domains.

Innovation by Necessity – Towards Practicality (not hype)

Since the performance of existing HPPs has made them indispensable, recent innovations are transforming the outlook for HPPs by leveraging advancements in processing and chemistry.

From Rigid to Reworkable Designs:

Vitrimers- one of the most innovative classes of polymers that bridge the gap between thermosets and thermoplastics. They induce a blend of the mechanical resilience of thermosets with the re-processing ability of thermoplastics. With this combination, they can be processed easily at elevated temperatures, allowing for reshaping, reparability, and recyclability with improved performance. A new class of epoxy-based vitrimers, Recyclamine, was developed by Aditya Birla and the University of Lyon. It exhibits a 90–95% recovery of tensile strength after two reprocessing cycles and maintains a modulus retention of more than 80% after heat aging at 200 °C for 1,000 hours. These properties expand the potential applications of these recyclable composites, enabling them to be utilized in emerging fields such as wind turbine blades, skis, kayaks, and even surfboards.

In collaboration with Vitrimer pioneer Ludwik Leibler, it continues to invest in and scale these vitrimers for use in construction (such as for reinforcement bars), renewable energy (including recyclable wind turbine blades), and numerous other industrial applications.

The University of Washington has recently developed a recyclable vitrimer-based printed circuit board. Here, the recycling process achieves 98% vitrimer recovery, 100% glass fiber recovery, and 91% solvent recovery, resulting in the production of new vPCBs without performance degradation.

Additive Manufacturing (AM) Ready HPPs:

Newly developed HPP grades optimized for additive manufacturing enable the creation of geometrically complex materials while minimizing waste, reducing the need for joints and seals, and enhancing dimensional stability. These AM-compatible HPP grades offer enhanced mechanical strength and chemical resistance, supporting applications across the aerospace, medical, and electronics domains. 3D-printed PEEK parts are now achieving surface finishes and mechanical properties that meet the requirements of demanding sectors. Invibio launched PEEK-OPTIMA™ AM Filament as a solution for the additive manufacturing of medical devices. Supported with Fused Deposition Modelling (FDM) and Fused Filament Fabrication (FFF) processes, the development of important products, such as cranio-maxillofacial (CMF) devices, spinal and orthopedic implants, has become cost-effective.

PFAS-Free and Sustainable Alternatives:

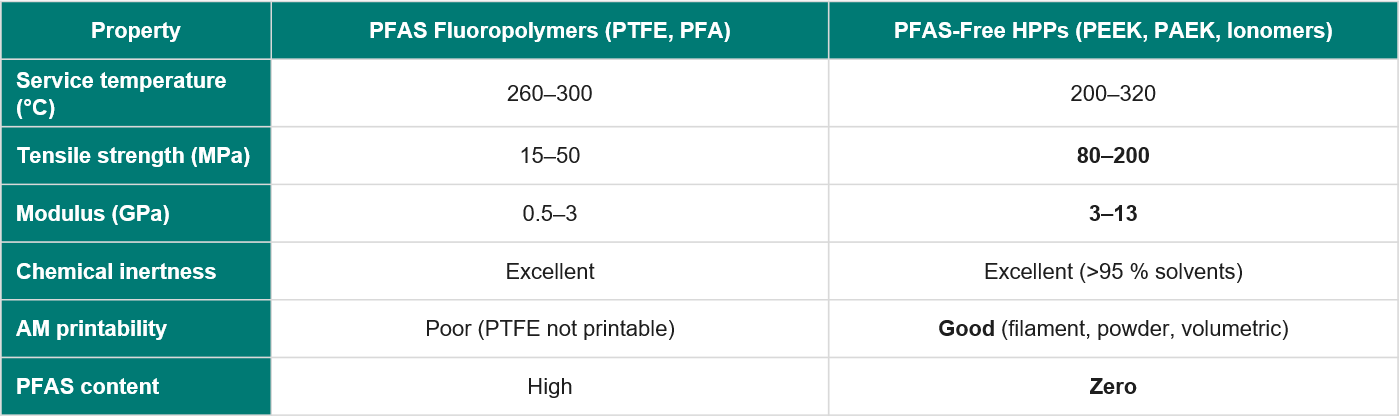

These AM-compatible directions also address the regulatory concerns with PFAS-free formulations. PFAS-free AM-ready HPPs target three critical metrics simultaneously:

- Achieving thermal stability above 200–250 °C

- Mechanical performance comparable to engineering HPPs (tensile strength ~80–130 MPa; modulus 3–10 GPa depending on reinforcement)

- Surface/chemical purity sufficient for semiconductor, medical, and microfluidic components (metal ion leach <10–50 ppb targets for critical parts).

With stricter PFAS regulations in the West and the rapid scale-up of AM manufacturing in Asia, the global PFAS-free HPP ecosystem is set to deliver materials that combine high performance with a clear purpose.

The regulatory clampdown has also fueled innovation in bio-derived HPPs for over a decade. Solvay’s Amodel® Bio PPA and Arkema’s Rilsan® T, based on castor oil, exhibit CO₂ reductions of 30–46% vs petroleum-based analogues and retain >95% mechanical performance. The next frontier for High-Performance Polymers (HPPs) lies in the lab, where they are pioneering bio-based materials, such as polyketones and sugar-derived monomers—an early step toward circularity in a linear, high-waste industry.

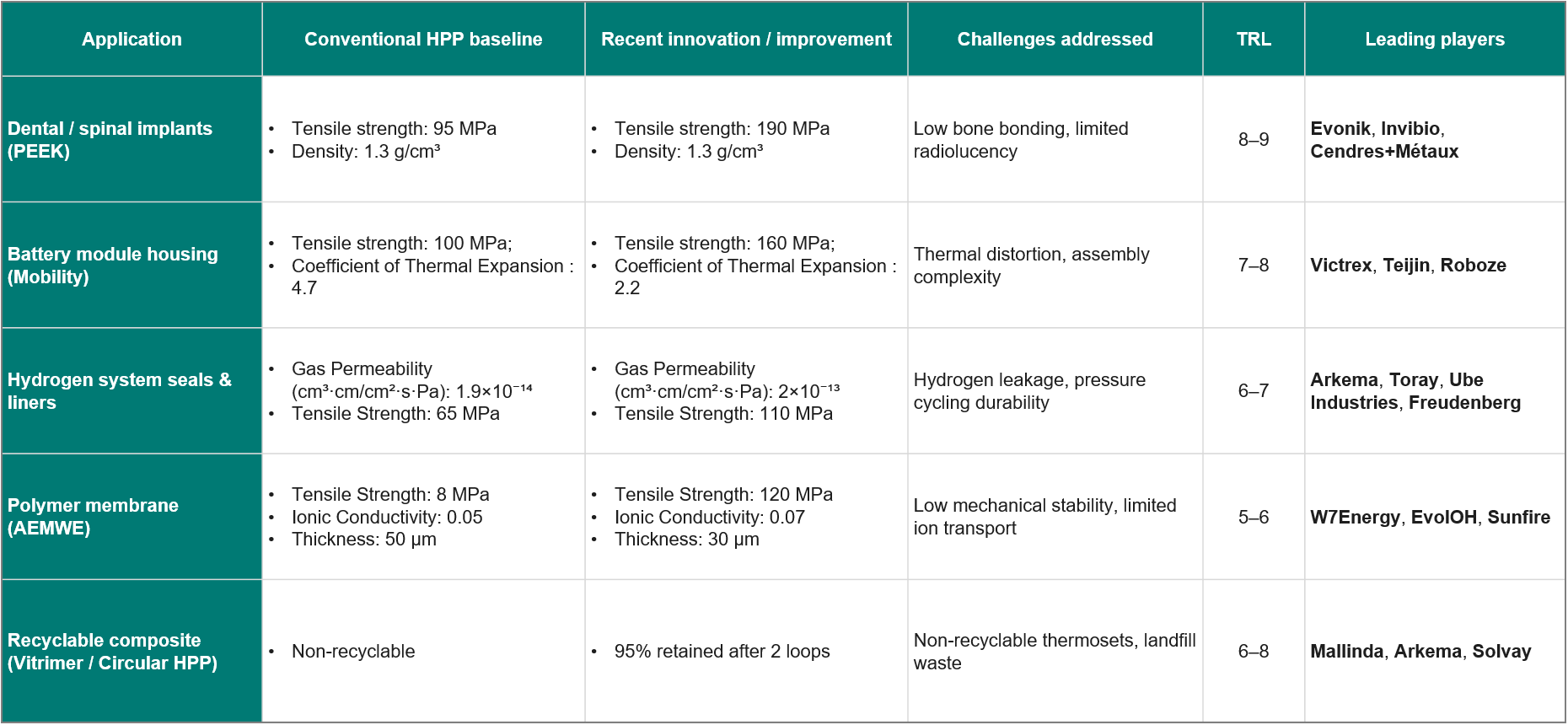

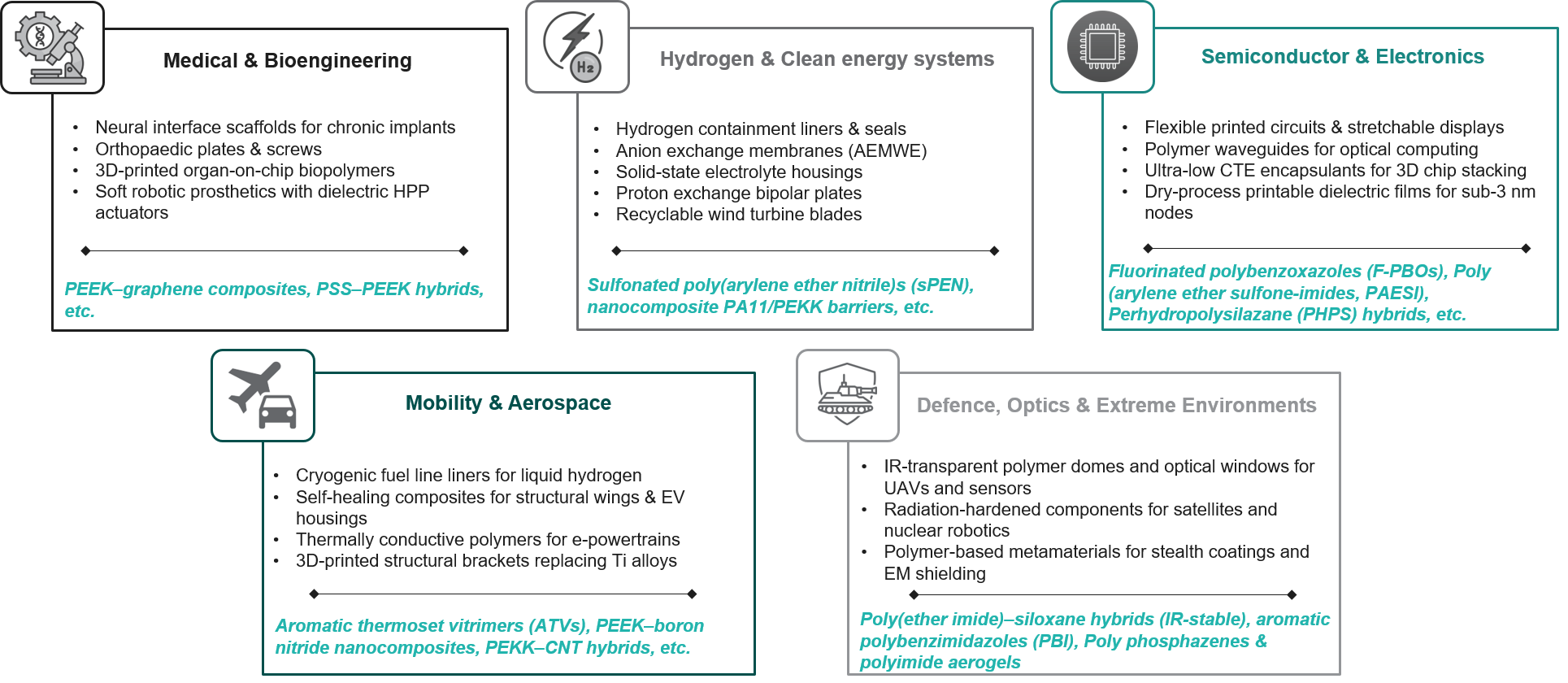

Applications Defining the Next Decade

High-performance polymers (HPPs) are no longer simply pushing mechanical or thermal limits across the healthcare, energy, semiconductor, and mobility industries. Material innovation is now closely tied to digital manufacturing, precision design, and application-driven performance.

The medical field is shifting the momentum toward next-gen customised implants for patients made from advanced polymers rather than metals. For example, in 2024, Curiteva announced its Inspire platform for 3D-printed transfacet interbody-fusion (TLIF) implants using AM-grade PEEK filament. These implants offer targeted porosity and trabecular architecture designed for faster bone integration. This enables not just comparable strength to conventional implants (~90–110 MPa tensile, ~4-5 GPa modulus), but also an improved anatomical fit and minimized post-operative adjustment. This shift from standard bars or plates to patient-printed lattice geometries underscores how HPPs are leaning towards a more design-for-function approach rather than simply material substitution.

The hydrogen and heavy-duty energy sector polymers need to meet extreme performance demands. Innovations such as advanced polymer-matrix systems incorporating PEEK blends for applications like composite battery and hydrogen tank enclosures effectively manage hydrogen permeation, pressure cycles, and elevated temperatures. This reflects the readiness of HPPs to transition from merely surviving harsh conditions to optimizing system reliability and efficiency for the clean-energy infrastructure.

A consistent pattern across various sectors shows that innovation is driven by application rather than just chemistry. R&D focuses on target metrics, with material systems designed to meet performance goals. Digital manufacturing speeds up iteration and reduces qualification times.

This shift from performance improvement to purpose-led innovation indicates that high-performance plastics are now enabling solutions for lighter, smarter, and more efficient technologies, rather than merely existing as stronger materials.

The Way Forward

High-Performance Polymers (HPPs) are transforming from just specialty materials into strategic assets that support global decarbonization and supply chain resilience. The next decade of value creation depends on two connected shifts: Circularity at Scale and Geopolitical Localization.

Circularity is transitioning the industry from “recyclable-if-possible” to “reprocessable-by-design.” Through advanced technologies like chemical depolymerization (as exemplified by Arkema’s Virtucycle), firms are establishing industrial-scale, closed-loop systems that target a 60% reduction in carbon footprint while maintaining mechanical integrity.

Simultaneously, localization is reshaping the global HPP map to ensure supply resilience. Europe’s “Green Mandate” (driven by REACH and PFAS bans) encourages local biopolymer and recycling hubs, such as Arkema’s PA11 plant in Normandy. North America’s “Digital Mandate” leverages additive manufacturing for on-demand aerospace and defense components. Asia-Pacific, conversely, doubles down on purity-led growth for demanding applications, such as semiconductors, meeting contamination thresholds of below 10 ppb.

This dual transformation presents a clear strategic imperative: stakeholders must incorporate circularity early, address high-value application pain points, and collaborate in system integration rather than treat the HPP as a commodity drop-in. The future of HPPs depends not only on achieving extreme properties for new applications but also on their sustainable and local deployment, forming a critical formula for next-generation material implementation.

We at Stellarix assist businesses to capture the full potential of high-performance polymers (HPPs), find and build connections across the value chain in order to position them at the forefront of next-generation HPPs. We would be more than happy to connect, discuss, and assist you in achieving your goal with a personalized approach.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.