GenAI Changing the Manufacturing Landscape

Generative AI causes a significant shift in the way manufacturing businesses innovate. This technology can analyze enormous amounts of data through machine learning algorithms, including market trends, customer preferences, and historical performance. It can now identify trends and generate fresh concepts. This could assist producers in finding innovative methods to produce items, streamlining production procedures, and developing fresh business concepts. Data-driven innovation also helps manufacturers remain ahead of the competition and meet evolving customer demands.

Significant Use of GenAI in Manufacturing

In the manufacturing sector, generative AI is a powerful tool that allows for fully automated workplaces and efficient operations. The possibility for more integration allows it to spot inefficiencies and provide insightful data about every component, including client relations, supply chain management, and manufacturing. This technology, which sustains high levels of productivity and efficiency throughout procedures, represents Industry 4.0 and smart manufacturing in the future. Automated tasks driven by generative AI are known to be finished quickly, more consistently, and error-free, resulting in increased productivity. The analytical skills of Gen AI can prevent expensive interruptions brought on by maintained breakdowns. It reduces costs by monitoring and resolving technical problems before they increase. AI can also reduce variability while enhancing product consistency through simulations to optimize manufacturing parameters and determine the ideal settings for high-quality output.

GenAI Models in Manufacturing Space

The transformative capabilities of GenAI have propelled the manufacturing industry into an era of intelligent operations. GenAI is a powerful tool for facilitating data-driven research and development (R&D) in manufacturing. Its capacity to transform raw data into valuable products and services has revolutionized the manufacturing sector.

| GenAI Model | Details | Application in Manufacturing |

| Variational Autoencoder (VAE) | Frequently used in processing images and videos | Intelligent assurance of quality |

| Generative adversarial networks | Used to generate new samples with a similarity to the training data | Used in the research & development of the product and inbound/outbound activities |

| Recurrent neural networks | Applied for sequential data processing, including time-series analysis and natural language processing | Better customer experience and product development |

| Long short-term memory networks | Type of networks that are used to analyze complex data | It can be used for smart supplier management, contract negotiation, and optimization |

Comparison with Traditional Quality Control Process

| Aspect | Traditional Quality Control Process | GenAI-based Quality Control Process |

| Scalability | Results generation cannot be so accurate | Complex scenarios can be easily handled, making them highly scalable |

| Execution | Requires human/manual intervention to test the results | Generate actionable results using automated testing, which reduces human intervention and generates concise reports |

| Prediction of Defects | Manually examining the flaws and not taking any preventative action | Consistently finding the defects by taking proactive and automated measures |

| Accuracy | Results generation can be not so accurate | Automatic testing generates more accurate results with great efficiency and less human intervention |

| Recognizing previous errors | Limited ability to draw insights from past data | Continuous learning and improvement over time |

GenAI Technologies in the Manufacturing Field

GenAI technologies have transformed manufacturing in several ways, including process optimization, productivity enhancement, and more effective resource allocation. These technologies are transforming the manufacturing sector and increasing competitiveness, efficiency, and creativity in a rapidly evolving global market.

- Deep Neural Network: In manufacturing, Deep Neural Networks forecast the quality of final products, resulting in improved product design and reduced defects. This technology detects possible equipment issues, thereby avoiding expensive downtime, enabling proactive maintenance, and ultimately saving time and money.

- 7D Printing: The innovative technology known as 7D printing can drastically change how we design and build products. It can produce complex, detailed, and intricate parts and products that are impossible with traditional manufacturing methods.

- Large Language Model: Large Language Models can help automate certain inspections to capture defects rapidly. To improve demand forecasting, inventory, and supply management, LLMs can help analyze and optimize all relevant supply chain data. This leads to a perfect balance between the demand and supply of raw materials, creating the right inventory stock.

- Digital Twin: Generative AI combined with digital twins has the potential to transform the manufacturing industry by sparking a significant surge of creativity. This partnership allows for immediate data analysis, anticipation of maintenance needs, fine-tuning of performance, simulation, and advanced decision-making. These technologies enhance operational efficiency, reliability, and innovation in manufacturing and maintenance processes.

Application of GenAI in Manufacturing

- Quality Control Assurance: GenAI analyses large datasets using sophisticated algorithms. This method swiftly finds anomalies and flaws that a manual assessment would ignore. GenAI makes real-time information analysis and threat identification possible with little effort.

- Supply Chain Enhancement: GenAI accurately predicts demand patterns. It matches production and inventory levels with actual demand by revealing hidden correlations, keeping stock levels at ideal levels, and reducing operating costs.

- Predictive Maintenance: GenAI can be used for predictive maintenance of manufacturing equipment by examining historical data to find trends that indicate upcoming equipment breakdowns.

- Design and Optimization of Products: GenAI algorithms examine various design possibilities and choose the best ones based on manufacturing, performance, and cost considerations.

- Optimization of Energy Efficiency: GenAI can optimize the utilization of energy in manufacturing processes by identifying areas for improved effectiveness and energy conservation. GenAI can assist manufacturers in lowering their operational costs and environmental impact by developing solutions that maximize energy consumption while meeting production needs.

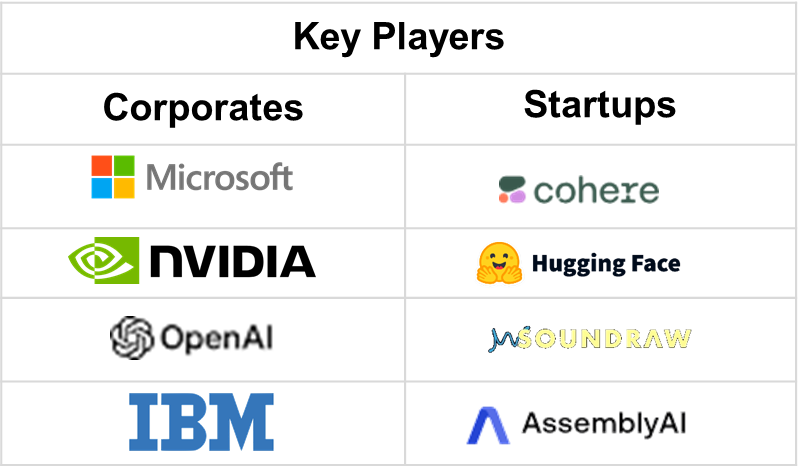

Key Players

Pegatron, an electronics manufacturer, used NVIDIA AI, NVIDIA Omniverse, and Universal Scene Description (OpenUSD) to build PEGAVERSE, which is a digital platform that transformed manufacturing operations. This platform by NVIDIA helps them fulfill their needs with real-time visibility, predictive maintenance, process optimization, remote operations, quality assurance, risk management, innovation, and cost reduction.

IBM® Watsonx.ai™ is the next-generation enterprise studio for AI developers that IBM introduced. The IBM® Watsonx.ai™ AI and data platform includes the ai™ AI Studio, which combines classic machine learning (ML) and new generative AI (gen AI) capabilities into an effective studio that spans the AI lifecycle.

Sustainable Design Techniques Using GenAI

In the manufacturing sector, generative AI stimulates environmentally friendly and sustainable product design. When designing products, it carefully considers several factors, including environmental effects and recyclability. This makes it possible for manufacturers to design goods that comply with environmentally friendly standards, reducing their environmental impact. Manufacturers can significantly lower their carbon emissions and actively contribute to environmental conservation by considering these factors. Manufacturers can align their processes with the concepts of green manufacturing by using generative AI to optimize product designs with a focus on sustainability. Manufacturers may create high-performing, economical, and ecologically friendly goods using generative AI.

Advancements

Recent advancements highlight the path to future developments:

- Wipro recently collaborated with Hewlett-Packard Enterprise to launch a GenAI solution, aiming to enhance operational excellence across industries such as financial services, healthcare, and manufacturing that significantly depend on IT support and customer service. The solution is designed to decrease the inflow of incidents by 30%, increase overall equipment effectiveness (OEE), shorten process cycle times, and reduce the mean time to resolution (MTTR) duration for GenAI applications by roughly 50% based on field testing results.

- The most recent study by Info-Tech has combined digital twins with GenAI, resulting in a significant advancement in design, simulation, and real-time predictive analysis within the manufacturing industry. This progress enables businesses to enhance their efficiency, sustainability, and adaptability in the highly competitive and ever-evolving global market.

Future Prospects

Smart manufacturing facilities can be created by combining GenAI with other technologies such as robotics and IoT. More sophisticated manufacturing processes could be expected to integrate GenAI with cutting-edge technologies in the future. Customized products that meet the needs and preferences of every consumer can be made with the help of generative AI. Generative AI will likely be used to make more customized products in the future. Additionally, GenAI can lower maintenance costs and downtime by predicting potential challenges before they emerge. As predictive maintenance positions become more complex, it could be anticipated that more manufacturers will employ generative AI.

Conclusion

Gen AI can completely transform the manufacturing sector by improving customer satisfaction, increasing output, cutting expenses, and reinventing every step of the process. It also has the power to improve business operations, promote economic expansion, and drastically change how businesses function and serve society as a whole. Even though the technology is still developing, companies should investigate and launch their own Gen AI programs because of the potential benefits that it brings.

Let's Take the Conversation Forward

Reach out to Stellarix experts for tailored solutions to streamline your operations and achieve

measurable business excellence.